Description

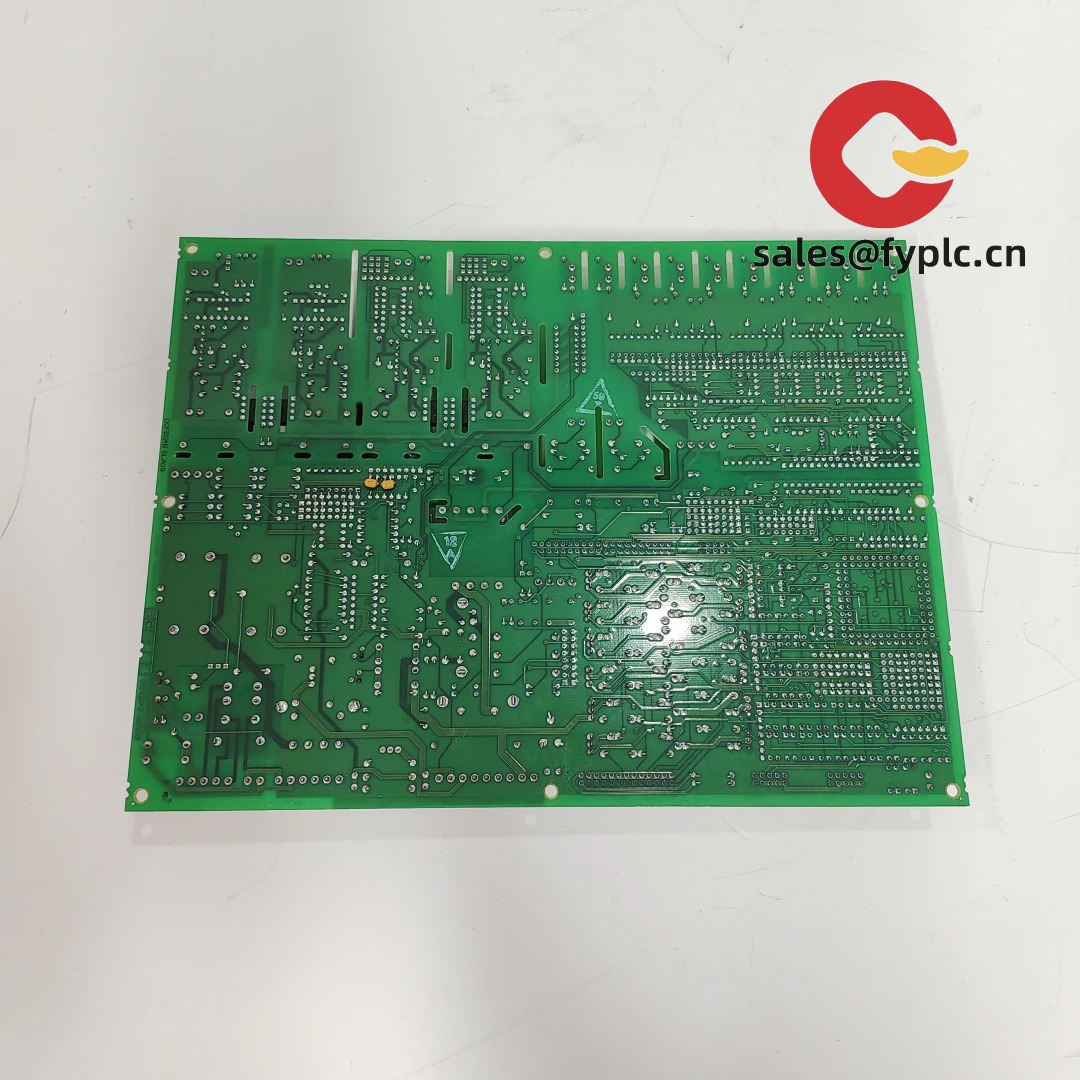

GE DS200DCFBG2BNC – Power Supply Board for GE Mark V and GE Drives Control Cabinets

The GE DS200DCFBG2BNC is a robust power supply board used across GE Mark V Speedtronic turbine controls and many GE industrial drive platforms. From my experience, it’s the go-to replacement when you need stable regulated DC rails (+5 V, ±15 V, +24 V) for logic, I/O, and analog sections in legacy GE panels. One thing I appreciate is how it drops into existing racks with minimal fuss—keeping downtime to a minimum in most cases.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express shipping: FedEx, UPS, DHL

- Every unit is function-tested before shipment; test report available upon request

Key Features

- Regulated multi-rail outputs – Provides +5 V, ±15 V, and +24 V DC rails typically used by CPU, I/O, and analog circuitry.

- Rugged GE design – Built for continuous operation in turbine and drive environments; seems to handle vibration and thermal cycling well.

- On-board protection – Fusing and test points simplify troubleshooting and help isolate downstream faults.

- Status indication – LEDs (where fitted) give quick visual checks of rail health; technicians usually spot issues faster.

- Direct replacement – Designed as a drop-in for compatible GE racks, keeping wiring and mounting the same.

- Backplane connectivity – Standard GE edge connectors interface cleanly with the host cabinet.

Technical Specifications

| Brand / Model | GE DS200DCFBG2BNC |

| HS Code | 8538.90 (Parts suitable for electrical control equipment) |

| Power Requirements | Supplied from cabinet auxiliary AC via isolation/rectification (commonly 115 VAC feed in GE panels); provides regulated +5 V, ±15 V, and +24 V DC rails to the backplane. |

| Dimensions & Weight | Approx. 330 × 280 mm; ~1.3 kg (typical board size for DS200 series) |

| Operating Temperature | 0 to +60 °C (cabinet-rated; ensure adequate airflow) |

| Signal I/O Types | DC output rails to backplane; status LEDs (where fitted); on-board test points; fused outputs. |

| Communication Interfaces | None (power distribution board; interfaces via GE backplane connectors) |

| Installation Method | Mounts on standoffs within GE Mark V / drive racks; mates to backplane; retain via screws and factory connector hardware. |

Application Fields

Typical deployments include:

- GE Mark V Speedtronic gas and steam turbine control cabinets

- GE industrial drive systems (DC2000 / EX2000 and related families)

- Balance-of-plant control panels using GE DS200-series backplanes

- Retrofit or life-extension projects where a stable multi-rail supply is required

A maintenance lead from a combined-cycle plant put it simply: “We swapped in DS200DCFBG2BNC during a hot-standby. Power rails came up in spec immediately, and commissioning took less than 30 minutes.”

Advantages & Value

- Direct compatibility – Drop-in board helps avoid cabinet rewiring and unplanned engineering hours.

- Reliability under load – Stable outputs reduce nuisance trips and intermittent I/O behavior.

- Cost control – Extends life of legacy systems without a full panel upgrade.

- Technical support – We can provide installation notes and rail verification steps; that shortens site time.

Installation & Maintenance

- Environment – Install in a sealed control cabinet per GE standards; maintain ventilation and keep ambient below 60 °C.

- Wiring – De-energize the cabinet, discharge DC rails, and observe ESD precautions. Verify backplane connectors are fully seated.

- Commissioning – After power-up, measure +5 V, ±15 V, and +24 V rails at test points or designated terminals. Check LEDs and alarms.

- Preventive maintenance – Quarterly dust removal (dry air), annual fuse inspection, and periodic verification of rail voltages under load.

- Spares strategy – In many cases it pays to keep one tested spare on hand; swap time is typically under one hour by a qualified tech.

Quality & Certifications

- Manufacturing quality – OEM-grade board design; produced under ISO 9001 quality systems in its original lifecycle.

- Certifications – Intended for use within CE/UL certified control panels; certification applicability depends on the complete system.

- RoHS – Legacy hardware may not be RoHS-compliant; many operators accept this for maintenance of installed base.

- Warranty – 365-day warranty from shipment; each unit function-tested prior to dispatch.

Commonly Paired / Supporting Components

- GE DS200SDCCG1A – Control/drive processor board often sharing rails from DS200DCFBG2BNC.

- GE DS200DTBBG1A – Terminal board for I/O interfacing in GE cabinets.

- GE DS215UCV / DS200UCV – CPU modules used in Mark V environments.

- GE DS200DSPCG1A – Digital signal processor card used in drive control applications.

Note: Model compatibility can vary by panel revision and site configuration. If you’re replacing an older DS200DCFB variant, share your rack ID or photos of the installed unit and connectors—we’ll double-check fit and pinout before you place the order.

Reviews

There are no reviews yet.