Description

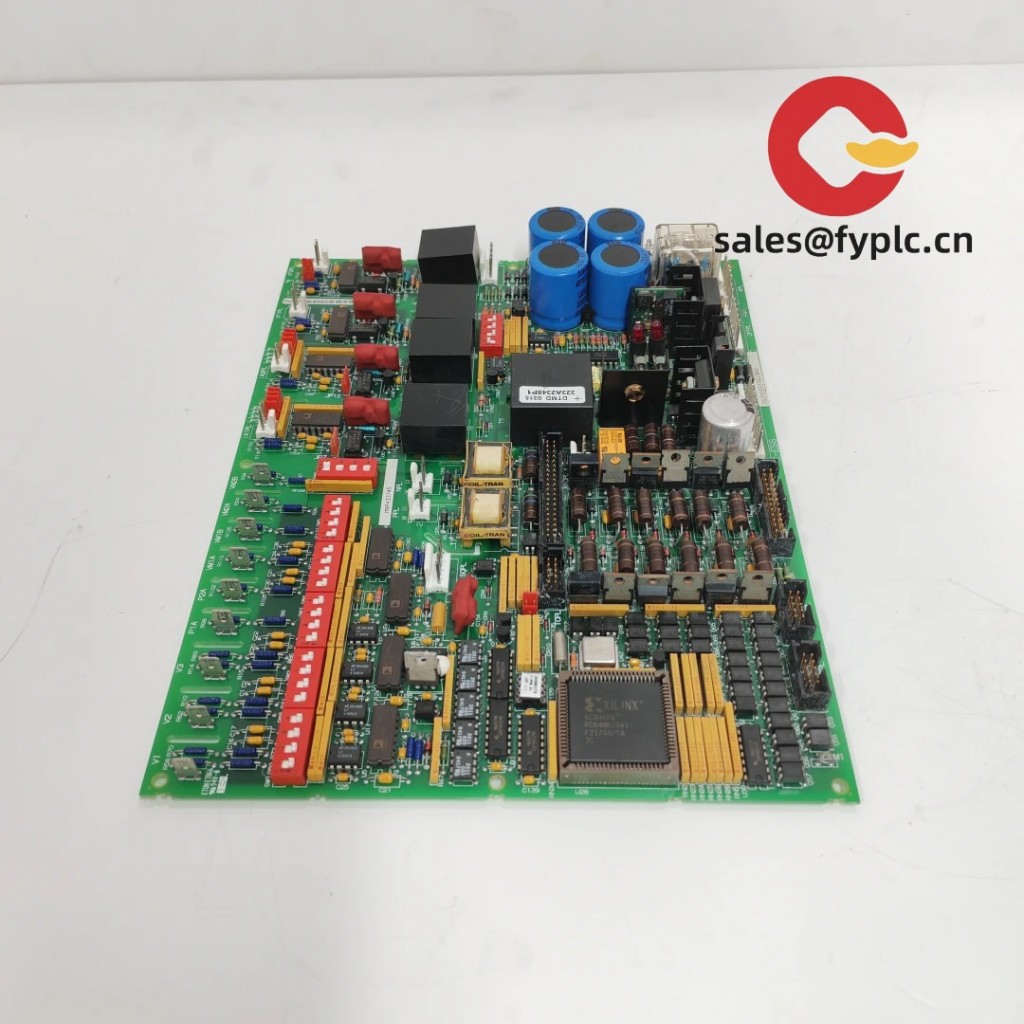

WOODWARD 8402-271 – Electronic Speed Control for Engines and Gensets

The WOODWARD 8402-271 is a proven electronic speed governor module used to keep diesel or gas engines—and the generators they drive—running at a stable RPM. From my experience, it behaves very much like the classic 2301A-series controls: magnetic pickup speed sensing, a robust actuator drive output, and adjustable droop/isochronous operation for tight speed regulation. You might notice that it integrates comfortably into older panels without demanding a redesign, which typically saves both time and cost during a swap-out or field upgrade.

Typical use cases include genset packages (prime and standby), marine auxiliaries, compressors, and industrial pumps. One thing I appreciate is how quickly technicians can tune it using standard Woodward procedures—gain, stability, and droop adjustments respond predictably, so you usually hit your load acceptance targets without chasing settings all day.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Stable speed regulation – Isochronous or droop control for steady RPM under varying load.

- Magnetic pickup speed input – Direct sensing from the engine flywheel gives fast, noise-immune feedback.

- Proportional actuator drive – Current output suitable for Woodward actuators to precisely position the fuel rack or throttle.

- Paralleling support – Analog load-sharing line (common on this series) for multi-set operation with DSLC/MSLC-type controllers.

- 24 VDC control power – Typically operates on 24 VDC systems found in most genset panels.

- Field-tunable response – Front-panel adjustments for gain, stability, and droop make commissioning straightforward.

- Rugged build – Industrial design intended for cabinet mounting in harsh environments.

Technical Specifications

| Item | Details |

|---|---|

| Brand / Model | WOODWARD 8402-271 (electronic speed control module) |

| HS Code | 9032.89 – Automatic regulating or controlling instruments |

| Power Requirements | 24 VDC nominal (typically 18–32 VDC) |

| Operating Temperature | Typically -20°C to +70°C (confirm exact rating for 8402-271 build) |

| Signal Input Types | Magnetic pickup (engine speed), discrete run/stop inputs (series typical) |

| Signal Output Types | Proportional actuator drive (current), analog load-sharing line (series typical) |

| Communication Interfaces | None (analog control architecture; no built-in serial comms) |

| Installation Method | Cabinet/chassis mounting; wiring via terminal strips; shielded sensor cabling recommended |

Application Fields

- Generator sets (prime/standby), with analog load sharing and DSLC/MSLC-type controls.

- Diesel and gas engines driving compressors, pumps, blowers, and process equipment.

- Marine auxiliary engines where steady RPM and droop behavior are required.

- Industrial sites upgrading from mechanical governors to electronic speed control.

Advantages & Value for Procurement

- Drop-in compatibility – Typically fits existing Woodward-style wiring and actuators, reducing retrofit work.

- Reduced downtime – Predictable tuning means faster commissioning and fewer site visits.

- Long lifecycle support – Woodward architecture with widely available spares and field know-how.

- Cost efficiency – Reuses existing magnetic pickups and actuators in many cases, avoiding wholesale panel changes.

- Technical backing – Documentation and tuning procedures are mature and well understood by field techs.

Installation & Maintenance

For best results, mount the control in an IP54 (or better) cabinet with good ventilation. Use a clean 24 VDC supply with proper grounding; if the engine has heavy cranking loads, a buffered supply helps avoid brownouts. Route the magnetic pickup cable separately from high-current lines and use shielded cable with the shield grounded at one end only.

- Wiring – Verify polarity and current capacity for the actuator output; follow torque specs on terminal strips.

- Tuning – Begin with nominal gain/stability settings; trim droop/isochronous behavior under load with step tests.

- Routine checks – Inspect pickup gap, tighten terminals, and clean cabinet filters every 6–12 months.

- Spare strategy – Keep one controller and one pickup sensor as on-site spares for critical services.

“We swapped in an 8402-271 on a 1.5 MW genset, reused the existing actuator and pickup, and were load-sharing within 2% after an hour of tuning.” — Maintenance Supervisor, IPP site

Recommended Supporting Components

- Woodward Magnetic Pickup Sensors – Engine-speed pickups sized for flywheel tooth count and mounting depth.

- Woodward Proportional Actuators – Common 24 VDC actuators (e.g., EGB/PG-series) matched to fuel systems.

- Woodward DSLC/MSLC Modules – For generator synchronizing and load sharing when operating in parallel.

- Quality Power Supply/UPS – Stabilizes 24 VDC control power during engine cranking and transients.

Quality & Certifications

- Manufactured under ISO 9001 quality systems (Woodward).

- CE marking and UL/cUL listings are available on many Woodward control builds; for 8402-271, we verify the exact marking prior to shipment.

- 365-day warranty from date of delivery.

Reviews

There are no reviews yet.