Description

ABB 5SHY3545L0010 + 3BHB013088R0001 + 3BHE009681R0101 (GVC750BE101) – IGCT Power Device and Gate Driver Kit for Medium-Voltage Drives

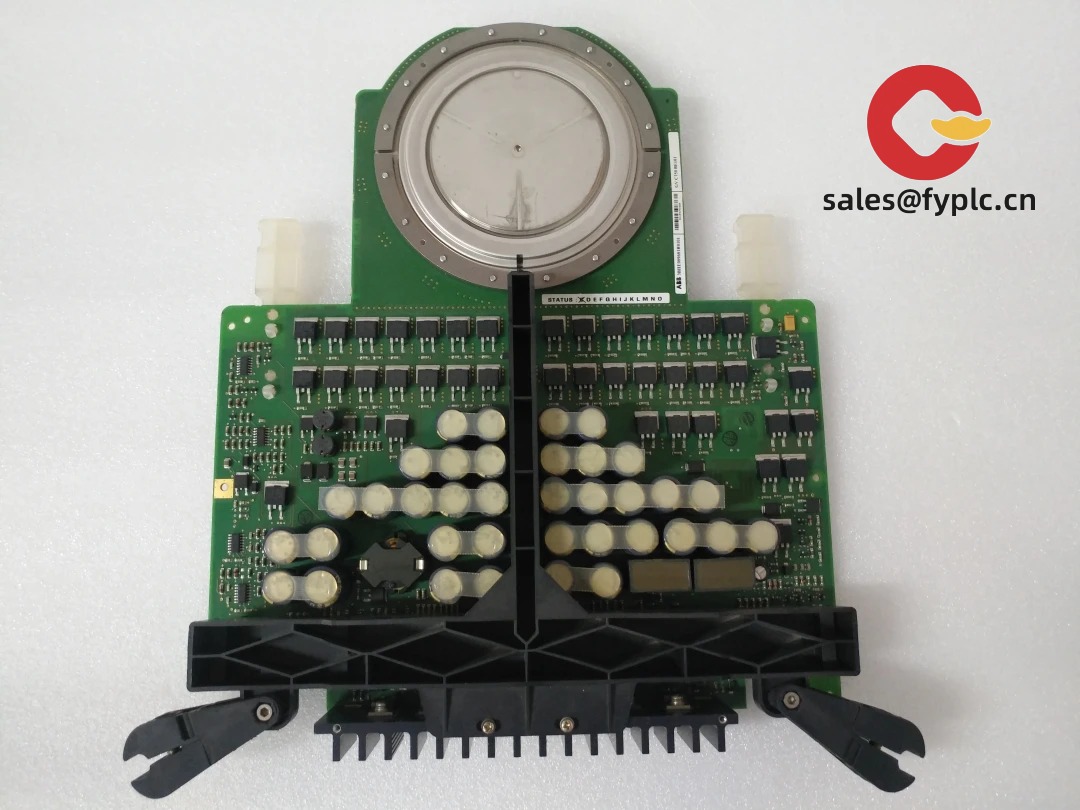

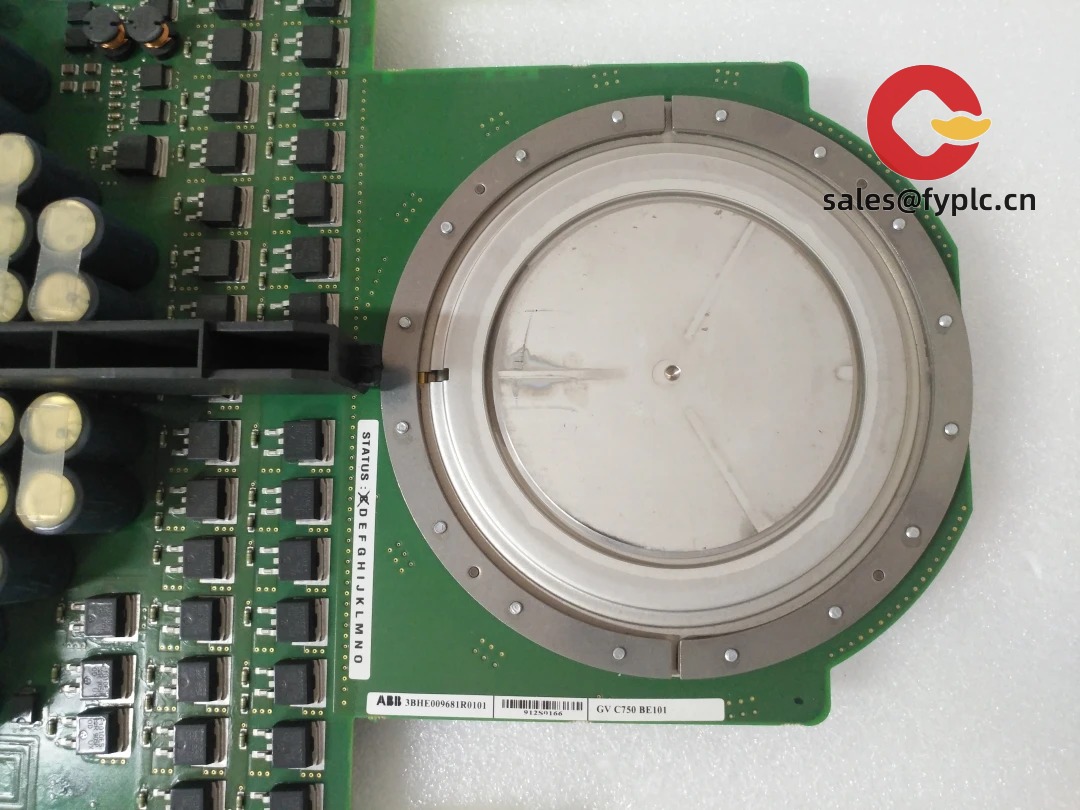

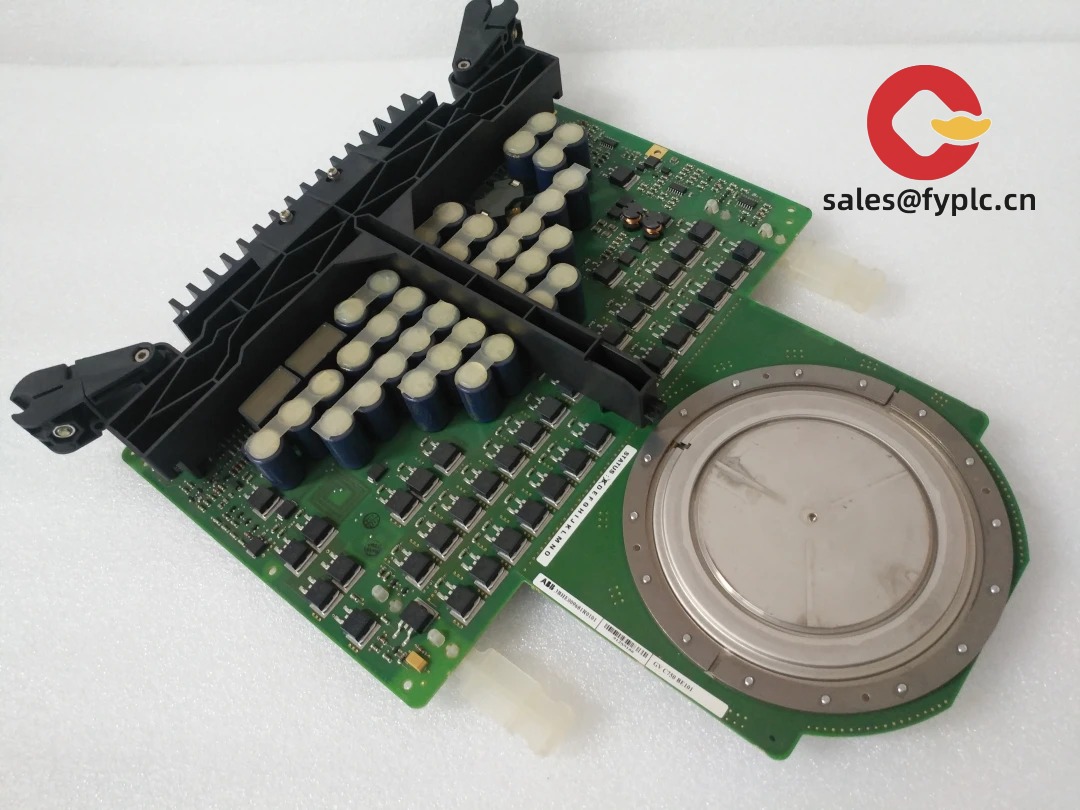

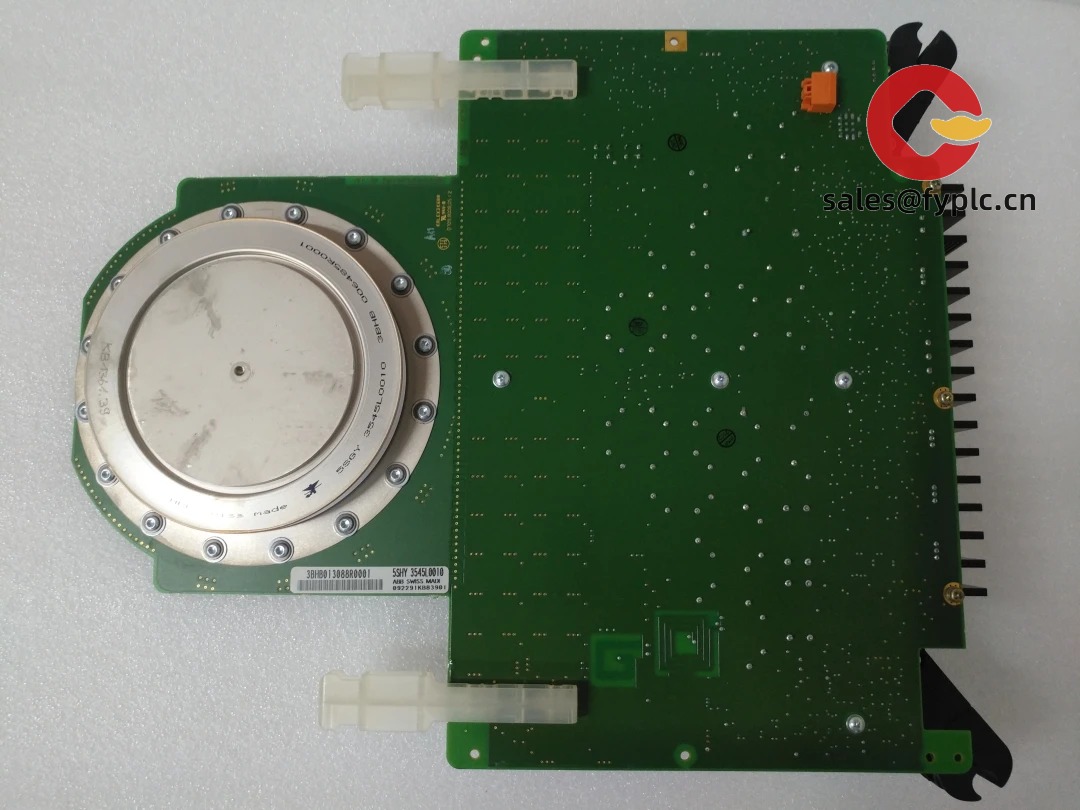

This set pairs the ABB IGCT power device 5SHY3545L0010 with the gate unit 3BHB013088R0001 and the control/driver board 3BHE009681R0101 (GVC750BE101). From my experience, this combination is commonly used in ABB medium-voltage drive platforms—often ACS1000/ACS6000 families—where a matched IGCT and driver chain keeps commutation stable and switching losses predictable. If you’re planning a stack overhaul or a like-for-like replacement, having the silicon and its driver electronics sourced as one kit typically avoids compatibility surprises.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock; no more than 1 month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery: FedEx, UPS, DHL

- Process: Confirm model/quantity → Proforma Invoice → Advance payment → Functional testing & packing → Final payment → Express shipment with tracking

Key Features

- Matched IGCT + driver chain – The 5SHY3545L0010 is paired with 3BHB013088R0001 and GVC750BE101 to keep gate charge, dI/dt, and protection thresholds aligned.

- Fiber‑optic triggering – Typically uses fiber‑optic links from the control board to the gate unit for robust noise immunity in MV cabinets.

- Medium‑voltage drive compatibility – Commonly applied in ABB ACS1000/ACS6000 stacks; minimizes requalification time during maintenance.

- Service‑friendly replacement – Drop-in hardware for planned shutdowns; no rewiring in most cases when replacing like-for-like parts.

- Thermal and electrical stability – Paired components help maintain switching margins and reduce nuisance trips under load swings.

Technical Specifications

| Brand / Model | ABB – 5SHY3545L0010 + 3BHB013088R0001 + 3BHE009681R0101 (GVC750BE101) |

| HS Code | 850490 (Parts of static converters/drive systems) |

| Power Requirements | Gate unit/control board: typically 24 VDC via drive backplane; IGCT device has no user LV supply |

| Dimensions & Weight | IGCT press‑pack ~Ø91 mm class; kit weight ~2–3 kg depending on mounting hardware |

| Operating Temperature | Electronics typically 0…45 °C cabinet ambient; silicon junction limits per ABB datasheet |

| Signal I/O Types | Fiber‑optic gate trigger and status; gate/cathode sense; driver interlocks and alarms via backplane |

| Communication Interfaces | Proprietary ABB drive backplane for control; fiber optics to gate unit; no user Ethernet |

| Installation Method | IGCT press‑pack clamped in the power stack; gate unit mounted near device; control board plugs into the drive rack |

Application Fields

You’ll typically see this set in medium‑voltage variable‑speed drives and converters where high efficiency and rugged switching are required:

- ABB MV drives (commonly ACS1000 / ACS6000) in pumps, compressors and fans

- Metals, mining, cement and chemical plants running 3–6.6 kV motors

- Marine propulsion and test benches with demanding duty cycles

- Lifecycle extensions and stack refurbishments to avoid full system upgrades

Advantages & Value

- Reliability: Matched components seem to reduce nuisance gate faults and improve transient behavior under load steps.

- Compatibility: Like‑for‑like replacement minimizes parameter tweaks; fiber links and backplane keep existing wiring intact.

- Procurement efficiency: One kit instead of multiple POs; reduces the risk of mixing mismatched revisions.

- Supportability: We can run functional checks and share power‑up/LED verification before shipment.

Installation & Maintenance

- Cabinet environment: Clean, dry, and well‑ventilated MV drive cubicle; keep ambient within the drive’s rated range.

- Mechanical assembly: Use OEM‑specified press‑pack clamping tools and force; ensure flat, clean heat‑sink surfaces.

- Wiring & optics: Route fiber‑optic links with minimum bend radius; verify Tx/Rx orientation and link integrity.

- Safety: LOTO on all MV sections; allow DC link to fully discharge; ESD precautions for boards and gate unit.

- Commissioning: Confirm 24 VDC supply tolerance, polarity, and ground scheme; check status LEDs and interlocks before enabling.

- Routine care: Quarterly dust removal, connector reseat checks, and periodic thermal scans of the stack under load.

Quality & Certifications

- Quality system: Manufactured under ISO 9001 processes (typical for ABB drive components).

- Compliance: Intended for use inside CE/UL‑listed MV drive systems; RoHS status may vary by production year.

- Warranty: 365‑day warranty from shipment date.

Supporting Components You Might Also Need

- Snubber capacitors/resistors matched to the stack

- Fiber‑optic patch cords and transceivers for the drive bay

- Cooling hardware (heat sinks, fans) and mounting insulators

- Current/voltage sensors and DC link components if you’re doing a broader overhaul

If you share the drive type, stack position, and existing part revisions, we can double‑check interchangeability of 5SHY3545L0010, 3BHB013088R0001, and 3BHE009681R0101 (GVC750BE101) and prepare test reports prior to shipment.

Reviews

There are no reviews yet.