Description

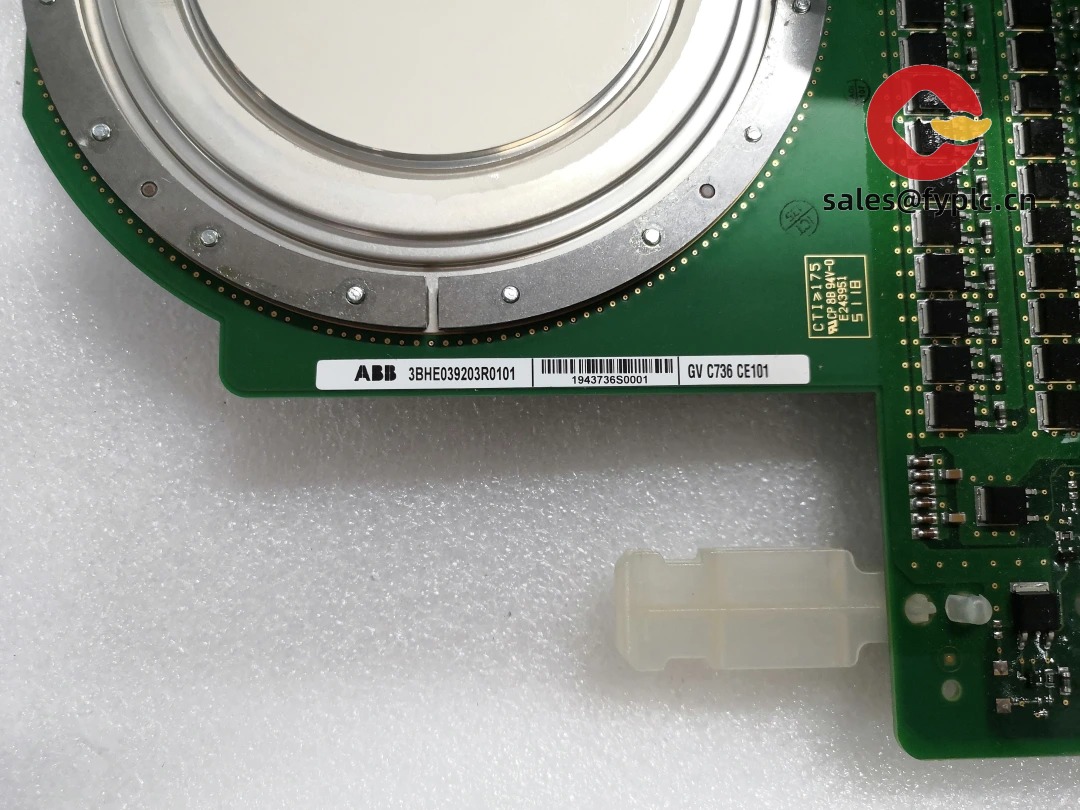

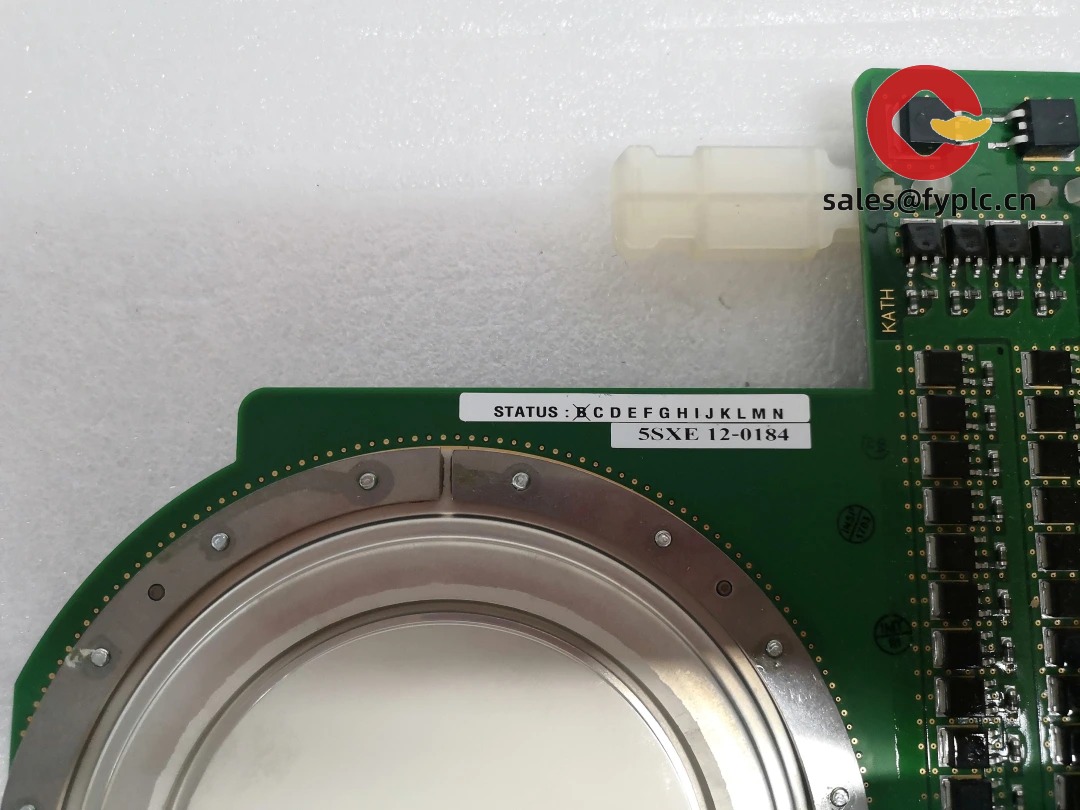

ABB 5SHY4045L0006 – 3BHB030310R0001 – 3BHE039203R0101 (GVC736CE101) – Matched IGCT, Gate Unit and Driver Board for MV Drive Stack Refurbishments

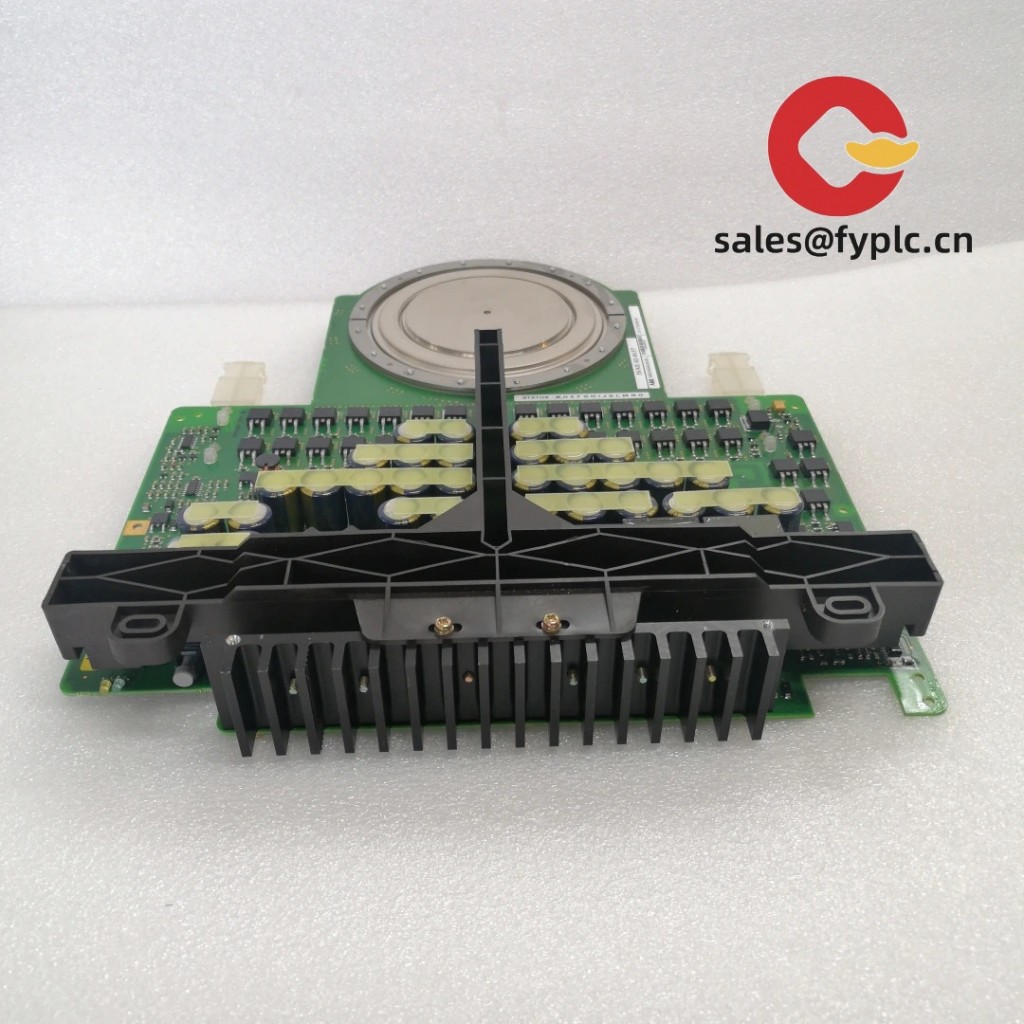

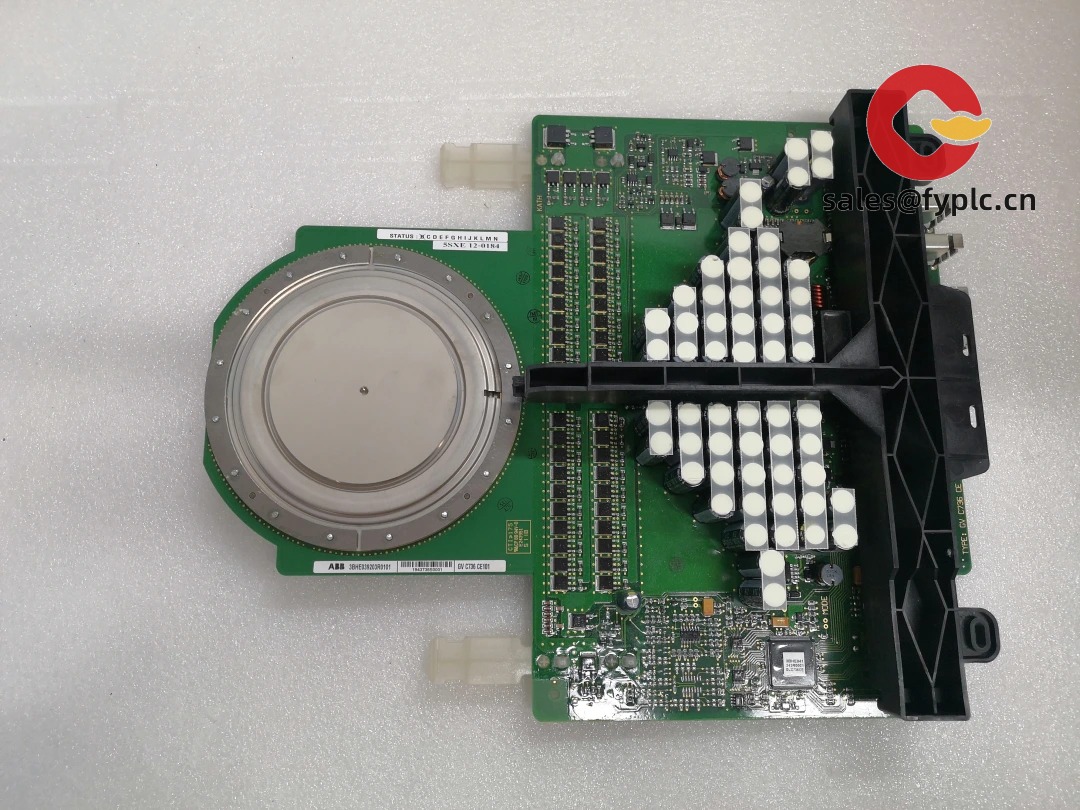

This combination brings together the ABB press-pack IGCT 5SHY4045L0006, the gate unit 3BHB030310R0001, and the control/driver board 3BHE039203R0101 (GVC736CE101). From my experience, ordering these as a matched chain keeps gate energy, protection thresholds, and timing behavior aligned—especially useful when you’re refreshing a stack position and want it to ramp cleanly without chasing revision mismatches. You might notice the fiber‑optic trigger links and the dedicated ABB backplane interface make commissioning feel predictable even in an electrically noisy MV bay.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Process: Confirm model and quantity → Proforma Invoice → Advance payment → Functional testing and packing → Final payment → Express shipment with tracking

Key Features

- Matched IGCT + driver chain – 5SHY4045L0006 with 3BHB030310R0001 and GVC736CE101 keeps dI/dt limits, gate charge and protection logic aligned.

- Fiber‑optic triggering – Optical Tx/Rx between driver board and gate unit provides robust EMC immunity in MV cabinets.

- Press‑pack reliability – Uniform pressure contacts typically tolerate thermal cycling better than plastic packages.

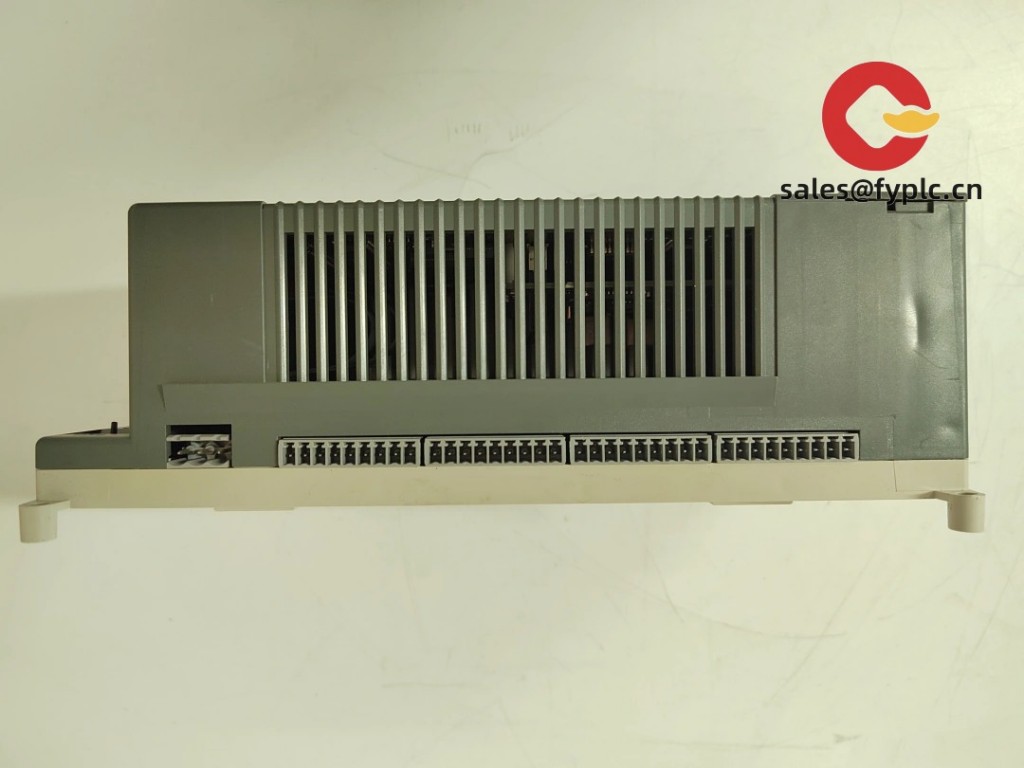

- Service‑friendly layout – Clamped device in the stack, adjacent gate unit, and a plug‑in control board make like‑for‑like swaps quick.

- Stable commutation – Consistent gating timing usually cuts nuisance trips during load steps or regeneration events.

Technical Specifications

| Brand / Model | ABB – 5SHY4045L0006 – 3BHB030310R0001 – 3BHE039203R0101 (GVC736CE101) |

| HS Code | 850490 (Parts of static converters / drive systems) |

| Power Requirements | Gate unit & driver board typically 24 VDC via the drive backplane; IGCT device has no user LV supply |

| Dimensions & Weight | Press‑pack IGCT (large‑diameter package); complete set ~2–3 kg depending on mounting hardware |

| Operating Temperature | Electronics typically 0…45 °C cabinet ambient; IGCT junction limits per ABB datasheet |

| Signal Input/Output Types | Fiber‑optic gate trigger/status; gate/cathode sense; interlocks and alarms via backplane |

| Communication Interfaces | Proprietary ABB drive backplane for control; no user Ethernet on the gate chain |

| Installation Method | IGCT clamped in the power stack; gate unit mounted adjacent; driver board plugs into the control rack |

Application Fields

Common in ABB medium‑voltage variable‑speed drives and converters where rugged switching and high efficiency are expected:

- ABB MV platforms (typically ACS1000 / ACS5000 / ACS6000) on pumps, compressors, and fans

- Metals, mining, cement, and chemical plants with 3–6.6 kV motors

- Stack refurbishments and lifecycle extensions during planned outages

- N‑1 spares programs to reduce downtime risk

Advantages & Value

- Reliability: Matched parts typically reduce intermittent gate faults and clean up transient behavior under load swings.

- Compatibility: Like‑for‑like fit keeps fiber links, backplane interfaces, and busbar geometry intact in most cases.

- Procurement simplicity: One coordinated kit lowers the risk of revision mismatches and requalification delays.

- Supportability: We can run functional checks and share power‑up/LED verification before shipment.

Installation & Maintenance

- Cabinet environment: Clean, dry MV cubicle; keep ambient within the drive’s rating.

- Mechanical assembly: Apply OEM‑specified press‑pack clamping force with a calibrated tool; ensure flat, clean heat‑sink faces.

- Wiring & optics: Route fiber links with proper bend radius; verify Tx/Rx orientation; keep gate/emitter leads short and symmetrical.

- Safety: Lockout/tagout; allow DC link to fully discharge; observe ESD precautions for boards and gate unit.

- Commissioning: Confirm stable 24 VDC supply, ground scheme, and interlocks; check status LEDs and diagnostics before enabling.

- Routine care: Quarterly dust removal, connector reseat checks, and periodic thermal scans of the stack under load.

Quality & Certifications

- Quality system: Manufactured under ISO 9001 processes (typical for ABB drive components).

- Compliance: Intended for use inside CE/UL‑listed MV drive systems; RoHS status may vary by production year.

- Warranty: 365‑day warranty from shipment date.

Share the drive platform, stack position, and your current part revisions, and we’ll double‑check interchangeability of 5SHY4045L0006, 3BHB030310R0001, and 3BHE039203R0101 (GVC736CE101) and prepare functional test results prior to shipment.

Reviews

There are no reviews yet.