Description

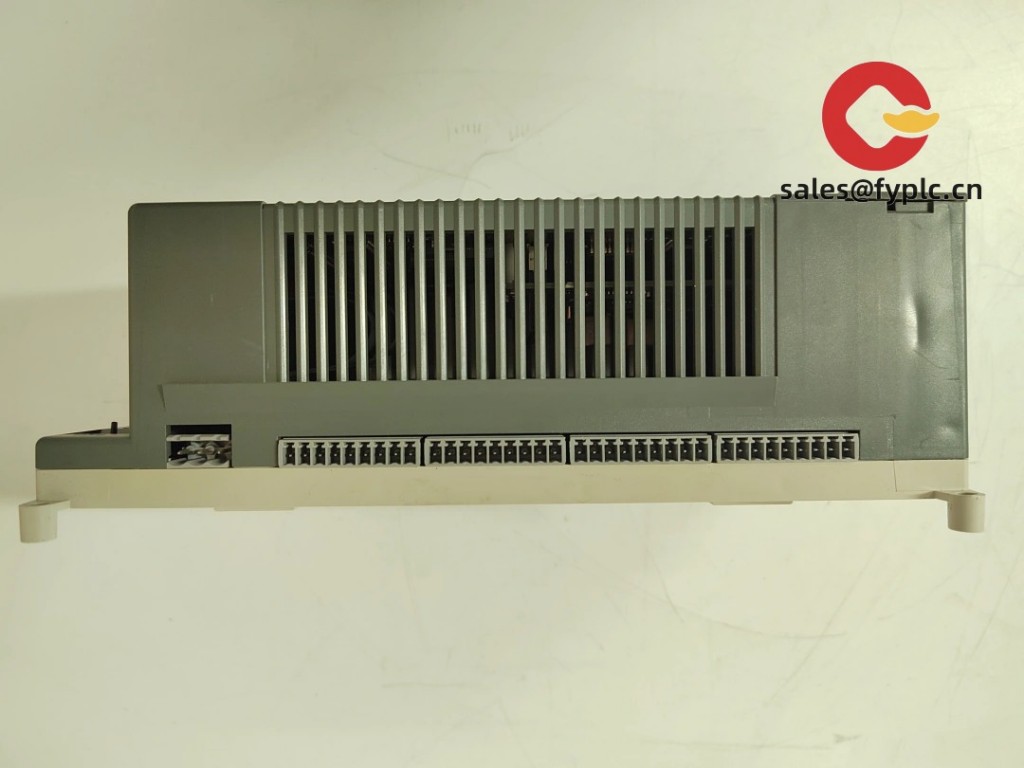

ABB 07KT98 (GJR5253100R4278) – AC31 CPU Module for Reliable Legacy Control and Brownfield Upgrades

ABB’s 07KT98, ordering code GJR5253100R4278, is a controller CPU from the AC 31 family. From my experience, this is the go‑to part when an installed AC 31 rack needs a like‑for‑like brain swap—no cabinet redesign, no field rewiring headaches. You might notice it plugs straight into the standard AC 31 base, talks to expansion I/O over the native backplane, and brings the system back online quickly during tight outage windows.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Process: Confirm model and quantity → Proforma Invoice → Advance payment → Functional testing and packing → Final payment → Express shipment with tracking

Key Features

- Drop‑in AC 31 CPU – Like‑for‑like replacement that restores operation without altering field terminations.

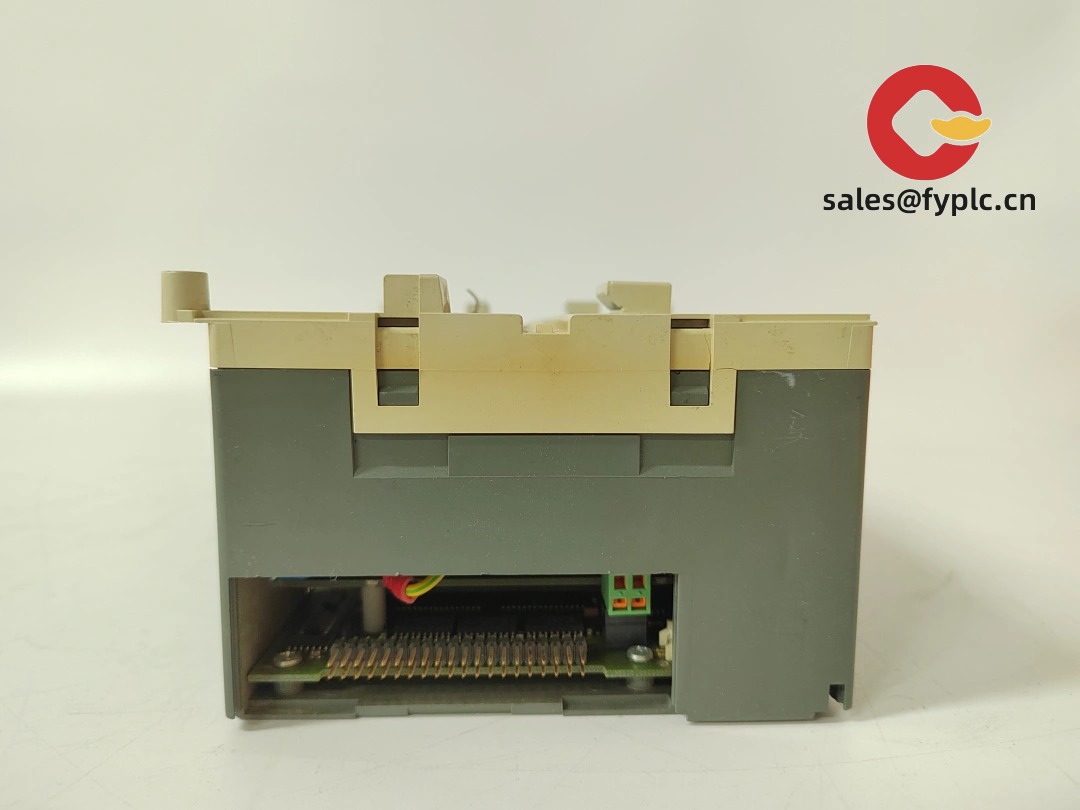

- Backplane integration – Communicates with AC 31 expansion I/O over the native bus; addressing typically remains unchanged.

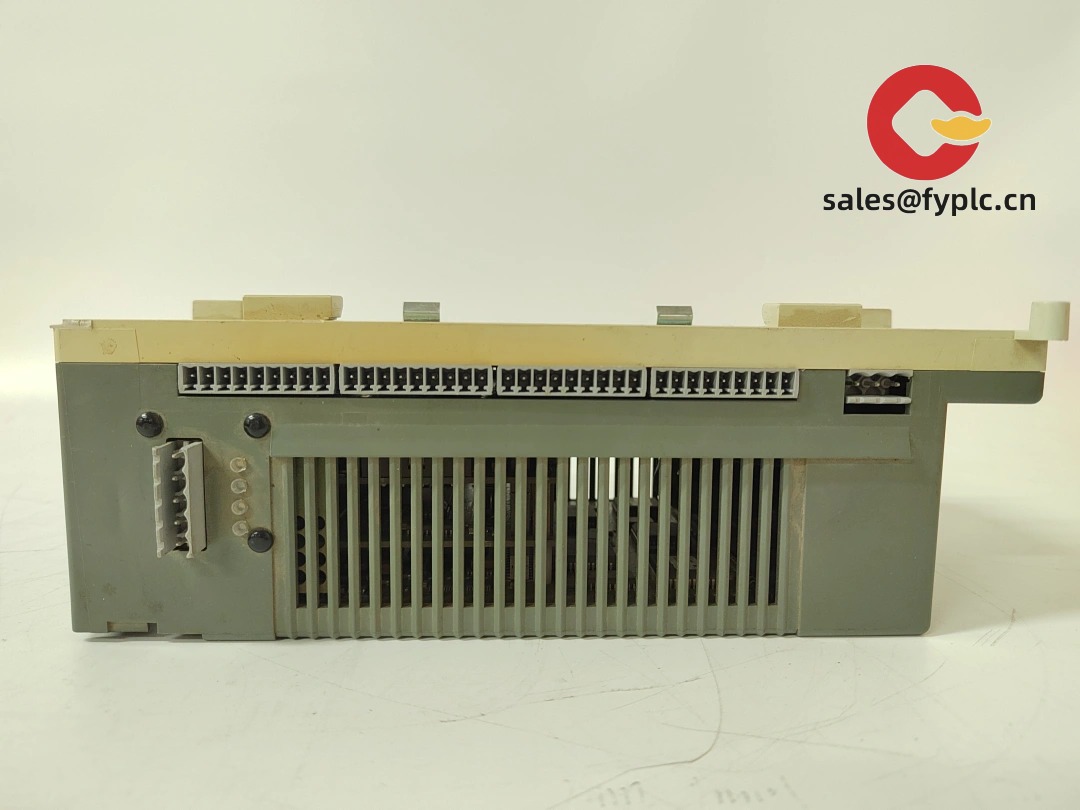

- Built‑in serial communications – Typically RS‑232/RS‑485 ports for programming and device links (S‑Bus/Modbus are common on this family).

- Deterministic control behavior – Stable scan performance for small to mid‑size machines, utilities and process skids.

- Service‑friendly – Front indicators and simple power‑up checks make commissioning quicker during tight stops.

Technical Specifications

| Brand / Model | ABB – 07KT98 (GJR5253100R4278), AC 31 CPU module |

| HS Code | 853710 (Programmable controller modules) |

| Power Requirements | Typically 24 VDC via the AC 31 base/backplane |

| Dimensions & Weight | Standard AC 31 footprint; ~0.4–0.6 kg class (typical for this series) |

| Operating Temperature | 0…55 °C cabinet ambient (typical for ABB PLC hardware) |

| Signal I/O Types | Backplane interface to AC 31 I/O bases; field signals remain on existing terminal bases |

| Communication Interfaces | RS‑232/RS‑485 serial for programming/devices; no integrated Ethernet on this class |

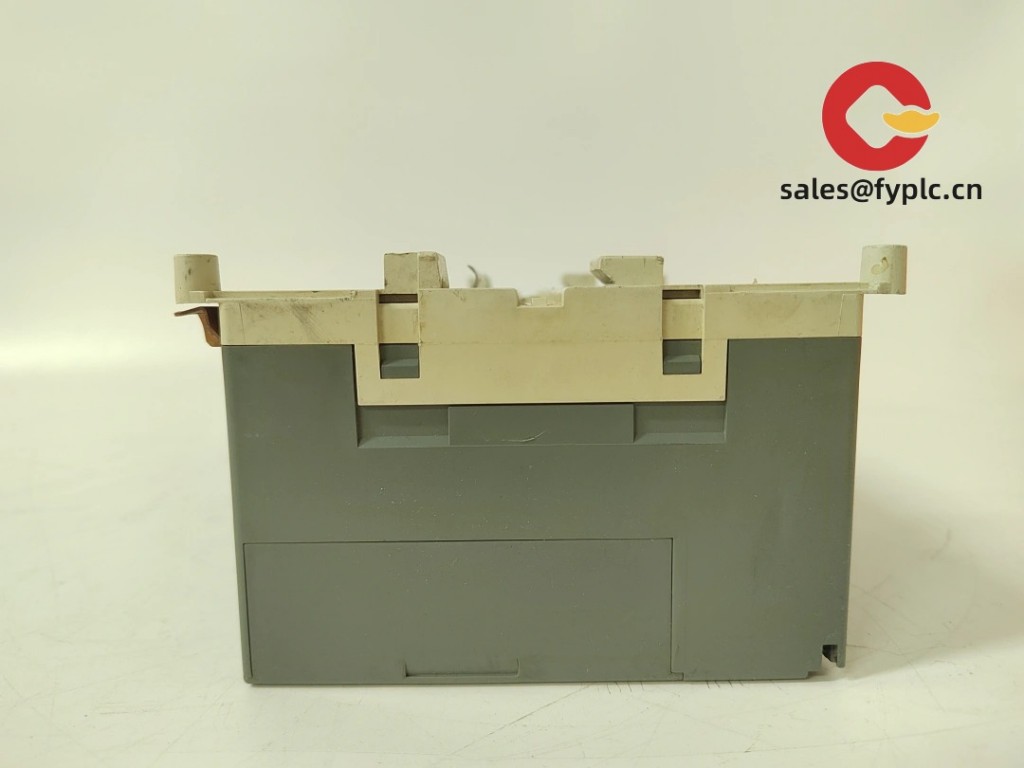

| Installation Method | DIN‑rail on AC 31 base; plugs to backplane with front‑accessible indicators |

Application Fields

Typical scenarios where 07KT98 fits well:

-

- Legacy AC 31 cabinets in water/wastewater, HVAC, and utilities

- OEM/discrete machines where a like‑for‑like CPU swap avoids a full migration

- Process skids with serial instruments and compact I/O counts

Brownfield life‑extension projects on ABB installed bases

Advantages & Value

- Reliability: Like‑for‑like CPU swaps typically stabilize scan behavior and clear intermittent controller faults.

- Compatibility: Keeps the existing AC 31 I/O bases and serial links intact—no rewiring in most cases.

- Downtime savings: Faster recovery than migrating platforms; minimizes requalification effort.

- Support: We can power‑up test, verify port activity/LEDs, and share a brief report before shipment.

Installation & Maintenance

- Cabinet setup: DIN‑rail mount on the AC 31 base; keep ventilation clear and follow derating guidance.

- Power & grounding: Provide a clean 24 VDC source; bond cabinet ground; segregate noisy loads from logic wiring.

- Programming & backups: Maintain a current project backup; verify any clock/battery settings if applicable.

- Serial links: Match baud/parity; set RS‑485 termination/polarity; ground shields correctly to avoid loops.

- Handling & safety: Power down before removal/insertion; use ESD precautions when handling the CPU and connectors.

- Routine care: Quarterly dust removal, connector reseat checks, and periodic review of diagnostic/event logs.

Quality & Certifications

- Quality system: Manufactured under ISO 9001 processes (typical for ABB PLC hardware).

- Compliance: Suitable for CE/UL compliant industrial control panels; RoHS status may vary by production year.

- Warranty: 365‑day warranty from shipment date.

Share your AC 31 rack layout, I/O base types, and any connected serial devices (protocol/baud), and we’ll confirm 07KT98 (GJR5253100R4278) compatibility and prepare a concise functional test record before dispatch.

Reviews

There are no reviews yet.