Description

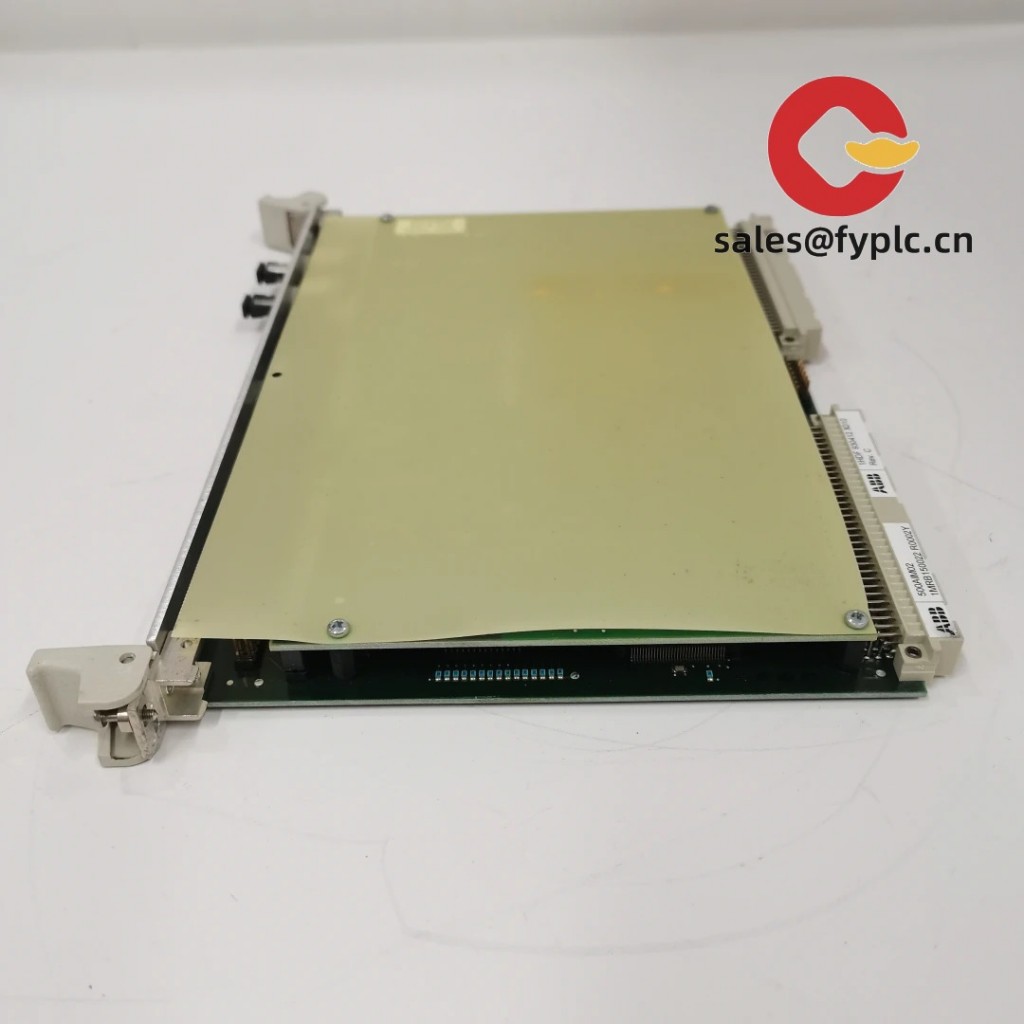

ABB 216VC62a‑P1000 (HESG324442R112) – Pulse/Control Interface Board for Medium‑Voltage Converter Stacks

The ABB 216VC62a‑P1000, identified on the label as HESG324442R112, is a pulse/control distribution board used inside ABB medium‑voltage (MV) drive and converter bays. From my experience, it’s the like‑for‑like spare you fit when a stack position starts throwing intermittent gating or interlock alarms and you need predictable ramp‑ups again—without reworking cabinet wiring. You might notice the “P1000” build tag typically aligns with a specific bay configuration, which helps keep timing and diagnostics consistent across similar positions.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Process: Confirm model and quantity → Proforma Invoice → Advance payment → Functional testing and packing → Final payment → Express shipment with tracking

Key Features

- Pulse/control distribution – Coordinates gating patterns and timing to gate units so commutation stays stable under load.

- Protection feedback handling – Aggregates desaturation, overcurrent and thermal signals back to the system controller.

- Backplane integration – Native fit in ABB MV racks; field wiring typically remains untouched during swaps.

- EMC‑robust signaling – Many builds use fiber‑optic trigger/status links to gate units, which helps in noisy MV bays.

- P1000 / R112 build alignment – Variant coding that, in many cases, keeps timing and diagnostics consistent across the installed base.

- Service‑friendly – Front LEDs and accessible test points make outage checks faster and more consistent.

Technical Specifications

| Brand / Model | ABB – 216VC62a‑P1000 (HESG324442R112) |

| HS Code | 850490 (Parts of static converters / drive systems) |

| Power Requirements | Typically 24 VDC via the drive backplane (on‑board DC/DC regulation) |

| Dimensions & Weight | Rack plug‑in PCB; compact card; weight commonly ~0.3–0.5 kg class |

| Operating Temperature | 0…55 °C cabinet ambient (typical for MV drive electronics) |

| Signal Input/Output Types | Backplane analog/digital feedback, interlocks, and trigger references; fiber‑optic Tx/Rx to gate units in many builds |

| Communication Interfaces | Proprietary ABB rack/backplane; no user Ethernet/serial on the board body |

| Installation Method | Rack‑mounted plug‑in card with edge/backplane connector and front retention hardware |

Application Fields

Deployed in ABB medium‑voltage converters and VSDs where robust gating and protection coordination are essential:

- ABB MV platforms (commonly ACS1000 / ACS5000 / ACS6000)

- Metals, mining, cement and chemical plants running 3–6.6 kV motors

- Stack refurbishments and lifecycle extensions during planned outages

- N‑1 spares coverage strategies to reduce downtime risk

Advantages & Value

- Reliability: A fresh board typically tightens gate timing and clears intermittent interlock/trip events.

- Compatibility: Like‑for‑like fit with ABB backplanes—no rewiring in most cases, which keeps outage work short.

- Cost & downtime: Faster restoration than redesigning a bay; avoids broad software requalification in many cases.

- Support: We can power‑up test, verify indicators and share a concise status report before shipment.

Installation & Maintenance

- Cabinet environment: Clean, dry, well‑ventilated MV cubicle; keep ambient within the drive’s rating.

- Handling: Use ESD precautions; avoid flexing the PCB; inspect the edge connector and standoffs before insertion.

- Connections: Seat fully on the backplane; if optical links are present, verify Tx/Rx orientation and clean ferrules.

- Safety: LOTO MV sections; allow the DC link to discharge fully; confirm 24 VDC polarity and grounding before enabling.

- Routine care: Quarterly dust removal, connector reseat checks, and quick indicator/health reviews under load.

Quality & Certifications

- Quality system: Produced under ISO 9001 processes (typical for ABB drive electronics).

- Compliance: Intended for installation inside CE/UL‑listed converter systems; RoHS status may vary by production year.

- Warranty: 365‑day warranty from shipment date.

Share your drive platform, bay/slot position, and any revision notes, and we’ll confirm interchangeability for 216VC62a‑P1000 (HESG324442R112) and prepare a concise functional test record before dispatch.

Reviews

There are no reviews yet.