Description

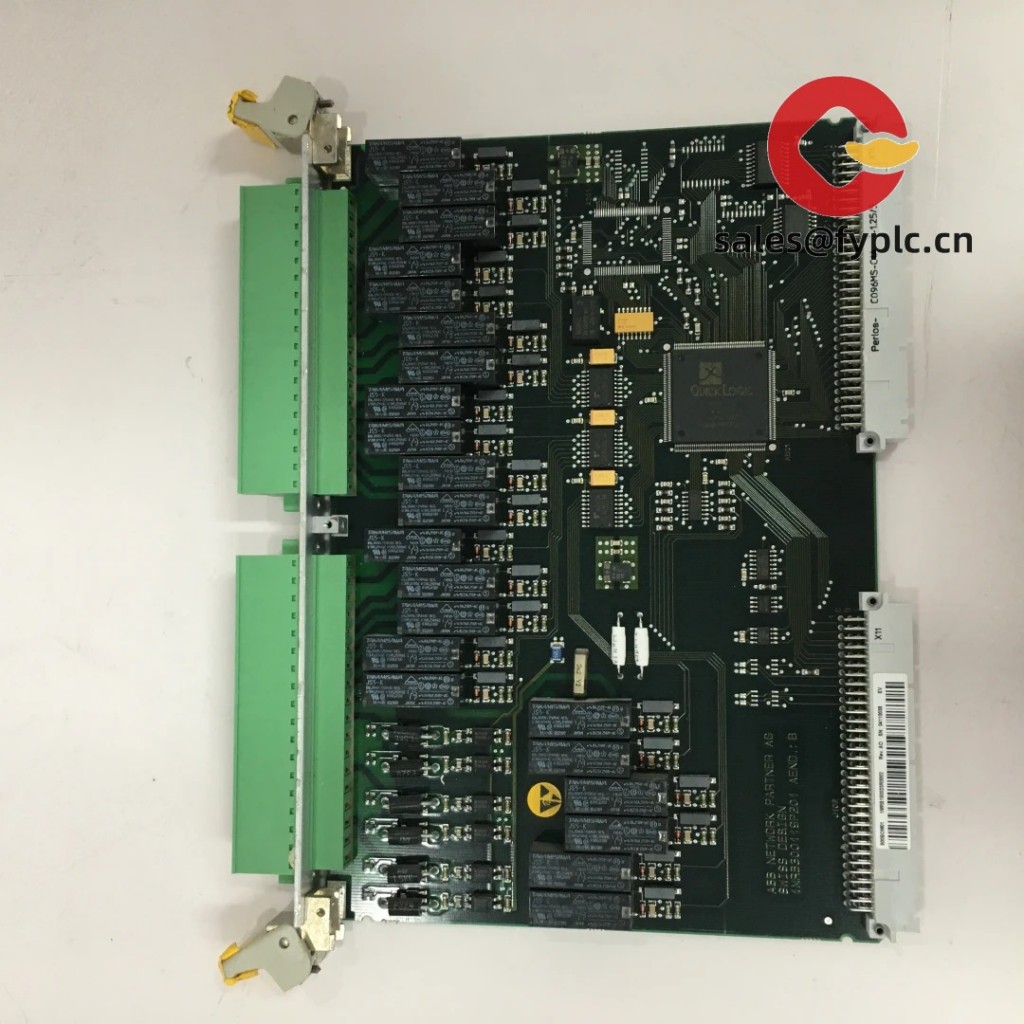

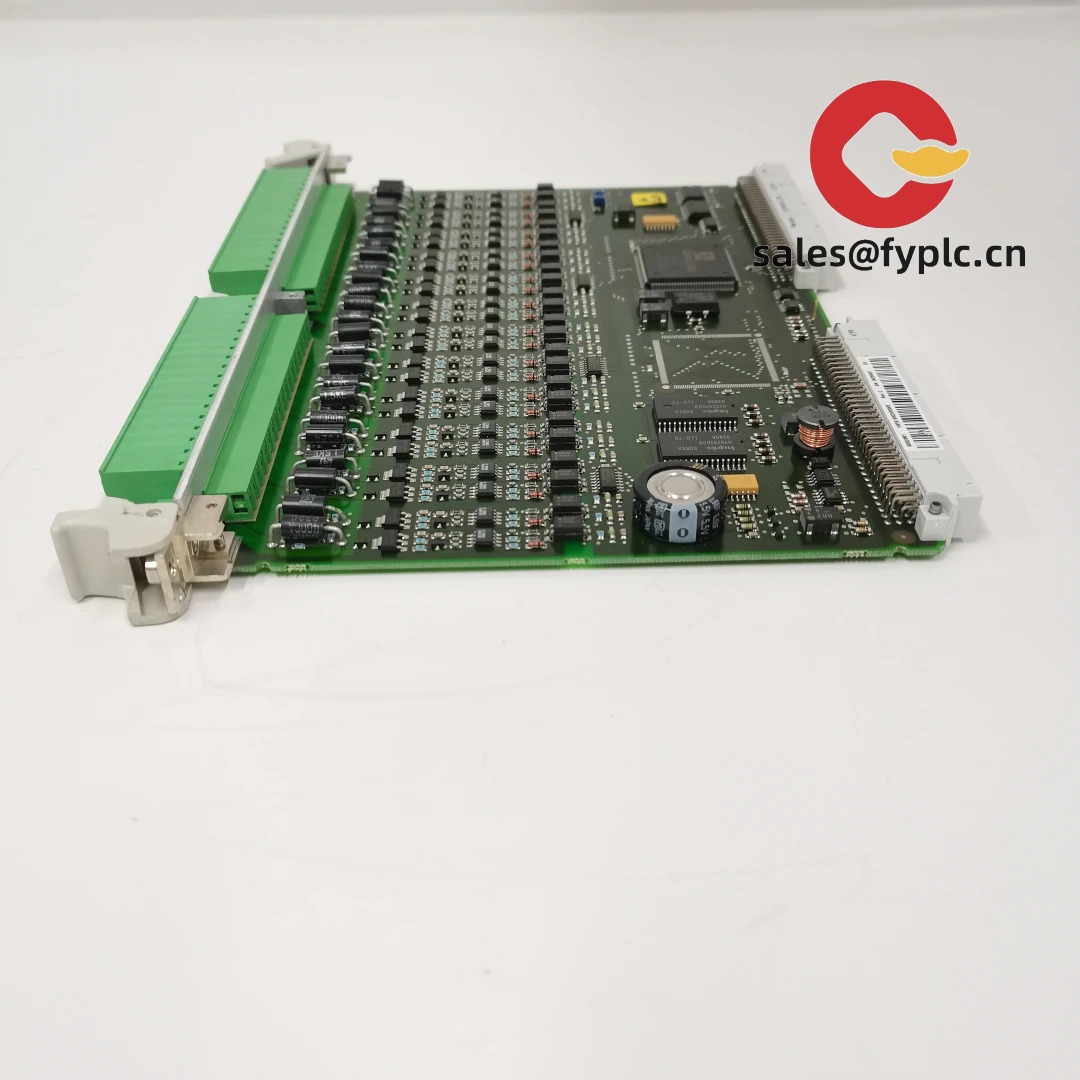

ABB 500BIM01 (Order Code: 1MRB150024R0002) – Baseplate I/O Module for ABB Industrial Drives

The ABB 500BIM01, supplied under order code 1MRB150024R0002, is a baseplate I/O module used inside ABB drive cabinets to bridge field wiring and the control electronics. From my experience, this module sits on the baseplate and handles the practical side of the drive’s discrete and analog signals—so when it’s healthy, interlocks, start/stop chains, and feedback loops behave exactly as expected. You might notice that its connectors and mounting points are laid out for quick, like-for-like replacement during a short outage, which is typically what maintenance teams want.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx / UPS / DHL

- Compatibility check: Share a photo of the drive nameplate and the module label; it usually speeds up fit confirmation and prevents returns.

Key Features

- Baseplate-mounted I/O – Interfaces field wiring to the drive’s control core; designed for direct, neat cable routing.

- Drop-in spare – Like-for-like replacement to reduce rewiring and keep parameters intact in most cases.

- Stable signal handling – Maintains reliable digital inputs/outputs and conditioned signals to avoid nuisance trips.

- Backplane connectivity – Mates with internal ABB drive connectors; external fieldbus handled by dedicated adapters when required.

- Service-friendly layout – Keyed plugs, labeled headers, and accessible mounting points shorten the maintenance window.

- Lifecycle extension – Practical way to extend the life of installed drives without a full retrofit.

Technical Specifications

| Brand / Model | ABB 500BIM01 (Order code: 1MRB150024R0002) |

| HS Code | 8538.90 (Parts suitable for electrical control apparatus) |

| Power Requirements | Powered from host drive internal LV rail; 24 VDC typical, low power consumption |

| Operating Temperature | 0 to +55 °C typical when installed in a ventilated cabinet (non‑condensing) |

| Signal Input/Output Types | Baseplate digital I/O and conditioned control signals via edge/backplane connectors; exact channel set depends on drive configuration |

| Communication Interfaces | Internal backplane interface to the control board; fieldbus (e.g., PROFIBUS/PROFINET) via separate ABB adapters if used |

| Installation Method | Baseplate-mounted, plug-in connectors; secured with standoffs/screws |

| Form Factor / Weight | Compact board-level module; lightweight component suitable for ABB drive cubicles |

Application Fields

Used across ABB AC/DC drive systems in continuous processes: metals lines, paper & converting, mining conveyors, oil & gas pumps, compressors, cranes/hoists, and general factory automation. A typical case is a plant where intermittent I/O faults or noisy feedbacks point to a failing baseplate module—replacing 500BIM01 usually stabilizes signals without changing the cabinet layout or PLC logic.

Advantages & Value for Procurement

- Reliability – Restores dependable I/O handling, reducing nuisance trips and unexpected stops.

- Compatibility – Intended for ABB industrial drive families; we validate part numbers, revisions, and host drive frames before shipment.

- Cost savings – Board-level maintenance is typically far cheaper than a cabinet retrofit and avoids long re‑commissioning.

- Short downtime – Drop-in mechanics and keyed connectors make changeouts fast during planned shutdowns.

- Technical backup – Guidance on parameter backup, signal mapping checks, and firmware alignment where applicable.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry, ventilated enclosure. Keep ambient 0…55 °C and avoid condensation or conductive dust.

- Safety & isolation – Lockout/tagout the drive, wait for DC bus discharge, and verify zero energy before handling.

- ESD controls – Use an antistatic wrist strap and handle by edges; do not touch component pins.

- Wiring & seating – Seat edge/backplane connectors fully; check grounding/PE continuity and terminal torque on field wiring.

- Signal checks – After replacement, verify DI/DO logic, interlock chains, and analog scaling. Run a controlled test with alarms monitored.

- Routine care – Annual dust removal and connector inspection; review event logs and update drive firmware when recommended by ABB.

Quality & Certifications

- CE compliance at the complete drive level; 500BIM01 is a component within the certified system.

- UL recognition typically applies to the drive assembly; this is a board-level spare.

- RoHS-compliant electronic components in most cases.

- Manufactured under ISO 9001 quality systems at the OEM level.

- Warranty: 12 months (365 days) against functional defects under normal operation.

A maintenance lead from a rolling mill told us this swap eliminated random start-permit drops after a weekend shutdown. If you can share the drive’s type code and a picture of the current module label, we’ll lock compatibility, reserve stock, and align shipment with your maintenance window.

Reviews

There are no reviews yet.