Description

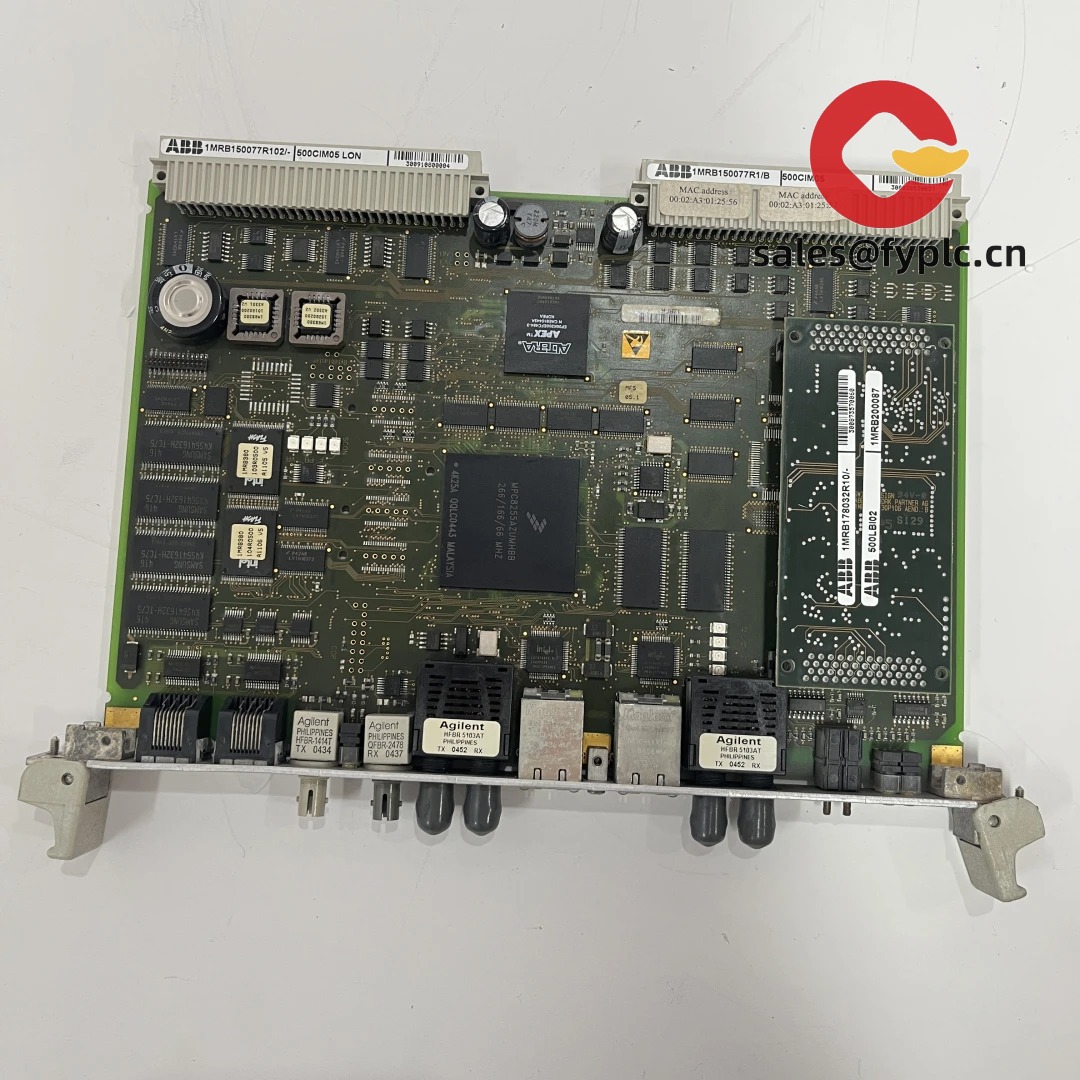

ABB 500CIM05 (Order Code: 1MRB150077R1B) – Communication Interface Module for ABB Industrial Drives

The ABB 500CIM05, tagged with order code 1MRB150077R1B, is a communication/interface module used inside ABB drive cabinets. From my experience, it typically manages the internal comms link between the main control board and peripheral boards, and coordinates I/O handover with the drive backplane. Plants use it as a like-for-like spare when sporadic communication alarms, intermittent interlock updates, or diagnostic link errors begin to pop up on older systems. One thing I appreciate is the service-friendly connector layout—it seems to be designed so maintenance can swap it quickly during a short stop.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx / UPS / DHL

- Pre-shipment check: Share a photo of the drive nameplate and the board label; it typically confirms the right revision fast and avoids returns.

Key Features

- Internal communication hub – Bridges the control core to the drive backplane so interlocks, status, and diagnostics flow reliably.

- Drop-in replacement – Like-for-like board to minimize rewiring and parameter work in most cases.

- Stability under load – Helps resolve intermittent “comms lost” or erratic update rates seen on aged interface boards.

- Backplane connectivity – Mates directly with ABB’s internal connectors; external fieldbus remains on dedicated adapters when present.

- Service-friendly design – Keyed headers, labeled connectors, and accessible mounting points support quick changeouts.

- Lifecycle extension – Keeps installed ABB drives productive without moving to a full retrofit project.

Technical Specifications

| Brand / Model | ABB 500CIM05 (Order code: 1MRB150077R1B) |

| HS Code | 8538.90 (Parts suitable for electrical control apparatus) |

| Power Requirements | Supplied from host drive LV rail; 24 VDC typical, low power consumption |

| Operating Temperature | Typically 0…55 °C inside a ventilated, non‑condensing cabinet |

| Signal Input/Output Types | Internal digital/analog control and status lines via backplane/edge connectors (channel set depends on drive configuration) |

| Communication Interfaces | Internal drive bus interface; external fieldbus (e.g., PROFIBUS/PROFINET/Modbus) handled by separate ABB adapters when installed |

| Installation Method | Plug-in board within the drive cabinet; mounted on standoffs/screws with keyed connectors |

| Form Factor | Compact board-level module suitable for ABB drive cubicles |

Application Fields

Typically found across ABB AC/DC drive systems in metals processing, paper & converting, mining conveyors, oil & gas pumping, cranes/hoists, and general factory automation. A common scenario: random “communication fault” or delayed interlock updates that only show under heat or vibration—replacing 500CIM05 often stabilizes the internal data path without touching PLC logic.

Advantages & Value for Procurement

- Reliability – Restores stable internal communications, reducing nuisance trips and unscheduled stops.

- Compatibility – Intended for ABB drive families; we verify part label and drive type/revision so it fits right the first time.

- Cost savings – Board-level maintenance is usually far cheaper than a full cabinet retrofit and shortens re-commissioning.

- Predictable downtime – Drop-in mechanics keep the swap inside a tight maintenance window.

- Technical support – Parameter backups, firmware alignment tips, and post-swap checks to keep risk low.

Installation & Maintenance

- Cabinet environment – Clean, dry, ventilated enclosure; keep ambient 0…55 °C and avoid condensation or conductive dust.

- Safety & isolation – Lockout/tagout the drive, wait for DC bus discharge, and verify zero energy before handling.

- ESD protection – Use a wrist strap and handle by board edges; avoid touching component pins.

- Connections – Seat backplane/edge connectors fully; confirm PE bonding and tidy cable strain relief.

- Firmware & parameters – Back up parameters; after installation, restore and check firmware compatibility where applicable.

- Functional test – Validate DI/DO updates, interlock timing, and a controlled ramp while monitoring alarms and temperatures.

- Routine care – Annual dust cleaning, connector re-seating, and event-log review; update drive firmware per ABB guidance.

Quality & Certifications

- CE marking applies at the complete drive level; this module is a component within the certified system.

- UL recognition typically at the drive assembly level.

- RoHS-compliant electronic parts in many cases for ABB spares.

- OEM manufacturing under ISO 9001 quality systems.

- Seller warranty: 12 months (365 days) against functional defects under normal operation.

A utilities engineer on a paper line mentioned that swapping this module cleared a stubborn comms alarm that only appeared after weekend shutdowns. If you can send the drive type code and a clear photo of the existing board label, we’ll lock compatibility, reserve stock, and align the shipment with your maintenance window.

Reviews

There are no reviews yet.