Description

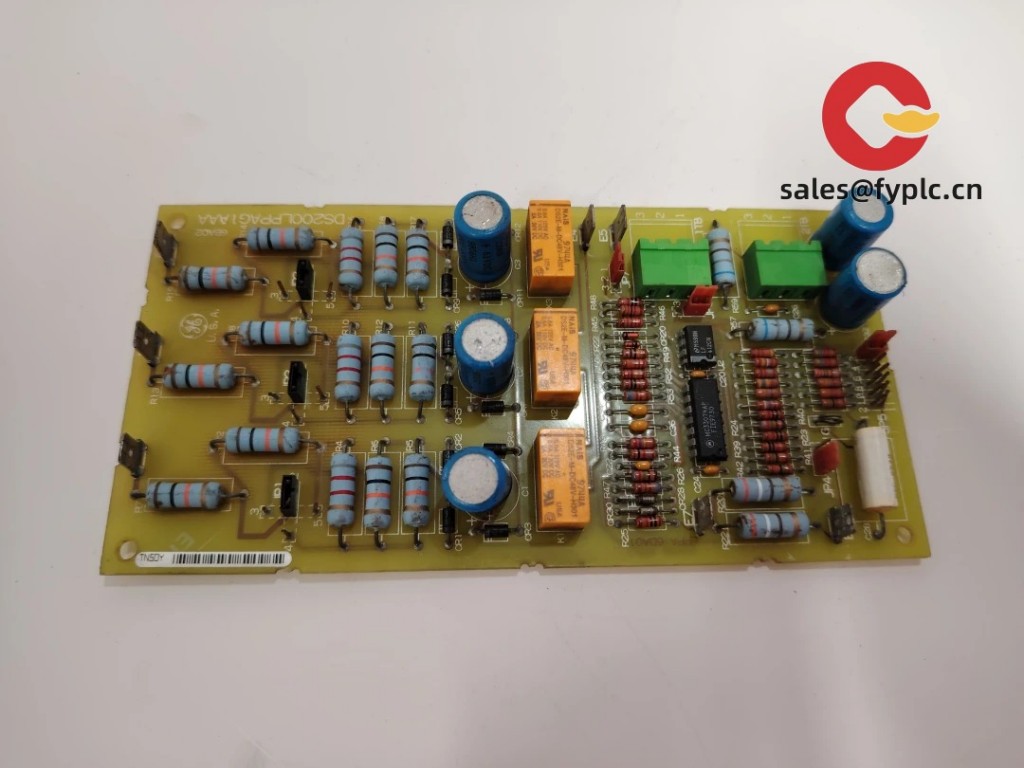

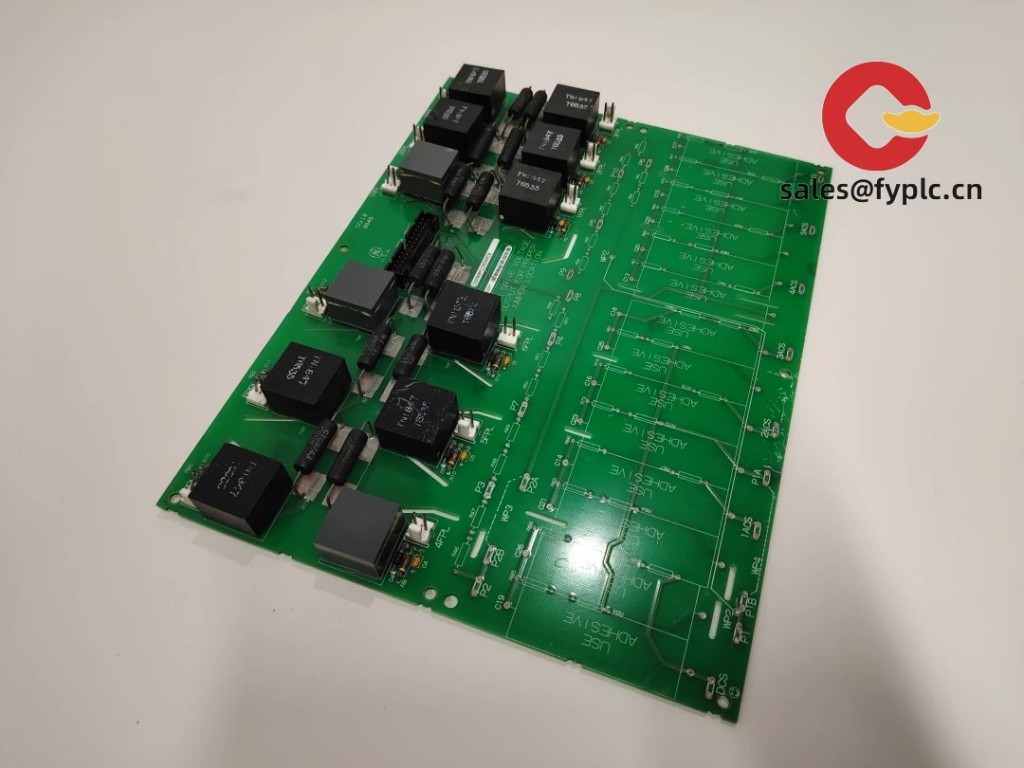

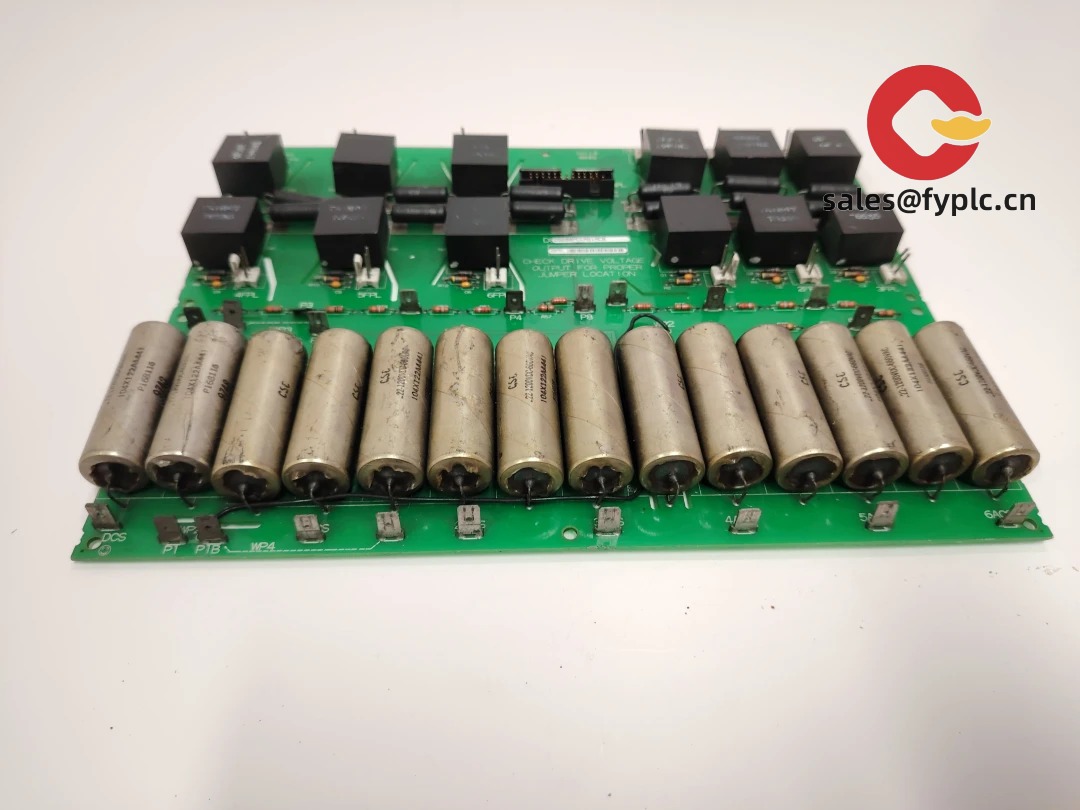

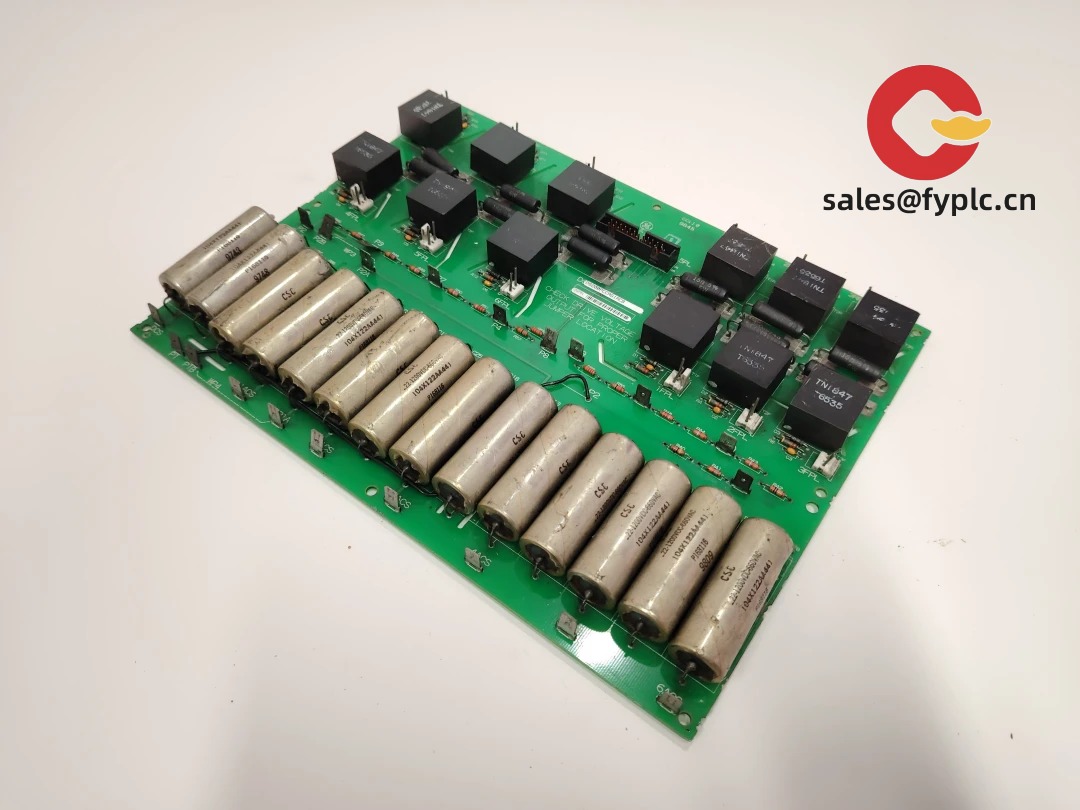

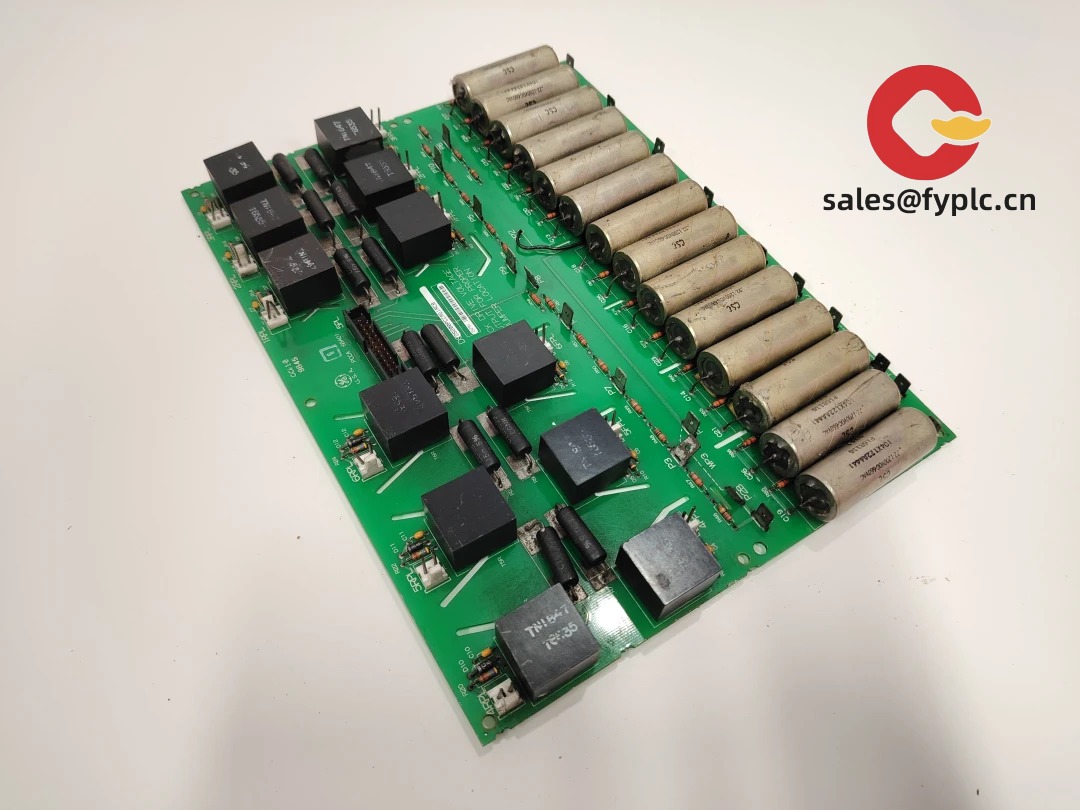

GE DS200PCCAG1ACB – PCCA Power Connect Card for GE DC/AC Drive Cabinets

The GE DS200PCCAG1ACB is a PCCA (Power Connect Card) used inside GE drive and exciter systems. From my experience, this board sits between the control core and the power section, routing gate/firing signals and conditioning key feedbacks from the power bridge. Plants typically see it in DC2000/AC2000 cabinets (and related EX-series exciters in some cases). One thing I appreciate is how its harness connectors are laid out—maintenance teams can swap it like‑for‑like during a short stop, without disturbing cabinet wiring or PLC logic.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx / UPS / DHL

- Compatibility check: Share the cabinet nameplate and a photo of the PCCA label/revision—this usually locks the correct match quickly.

Key Features

- Power section interface – Routes firing/gate signals to the power bridge and returns conditioned current/voltage feedbacks for control.

- Protection pathways – Supports over‑current/over‑voltage and permissive status lines so interlocks behave consistently.

- Drop‑in spare – Like‑for‑like replacement for PCCA cards in GE DS200‑series cabinets to keep wiring and parameters intact in most cases.

- Stable operation – Typically resolves nuisance trips tied to marginal bridge feedbacks or aging connectors.

- Service‑friendly design – Keyed headers, labeled positions, and accessible mounting points make changeouts straightforward.

Technical Specifications

| Brand / Model | GE DS200PCCAG1ACB (PCCA Power Connect Card) |

| HS Code | 8538.90 (Parts suitable for electrical control apparatus) |

| Power Requirements | Powered from host cabinet LV rails; typically +5 V and ±15 V available from the drive’s auxiliary supply |

| Operating Temperature | 0…55 °C typical when installed in a ventilated, non‑condensing enclosure |

| Signal Input/Output Types | Gate/firing outputs to power bridge; conditioned current/voltage feedbacks and protection/status lines via harness connectors |

| Communication Interfaces | Internal cabinet harness/backplane only; external fieldbus handled by companion control boards |

| Installation Method | Plug‑in board secured with standoffs/screws; keyed connectors to prevent mis‑seating |

Application Fields

Used across GE DC2000/AC2000 drives and, in many cases, EX‑series exciters in metals processing, paper & converting, mining conveyors, oil & gas, cranes/hoists, and large process fans. A typical scenario is sporadic commutation or start‑permit drops tied to unstable bridge feedbacks—replacing the PCCA often stabilizes gate routing and feedback conditioning without changes to PLC logic.

Advantages & Value for Procurement

- Reliability – Restores clean feedback paths and consistent firing logic, reducing nuisance trips and unplanned stops.

- Compatibility – Designed for GE DS200‑series cabinets; we verify part number, revision letters (ACB), and host type before shipment.

- Cost control – Board‑level maintenance is typically far cheaper than a cabinet retrofit and shortens re‑commissioning.

- Predictable downtime – Drop‑in mechanics and labeled connectors keep the swap within a tight outage window.

- Technical backup – Guidance on harness mapping, revision matching, and post‑swap checks to lower risk.

Installation & Maintenance

- Cabinet standards – Install in a clean, dry, ventilated enclosure. Keep ambient 0…55 °C; avoid condensation and conductive dust.

- Safety & isolation – Lockout/tagout the cabinet, wait for DC bus discharge, and verify zero energy before handling.

- ESD handling – Use an antistatic wrist strap; handle the board by its edges and avoid touching pins.

- Harness seating – Mark and re‑seat all keyed connectors; verify PE/ground continuity and strain relief on cables.

- Functional checks – After swap, verify permissives, run a controlled ramp, and monitor alarms; confirm firing synchronization where applicable.

- Routine care – Annual dust cleaning, connector inspection/re‑seating, and event‑log review; firmware applies to companion control boards, not the PCCA itself.

Quality & Certifications

- Used within CE‑conformant drive assemblies; the module forms part of the certified system.

- UL recognition typically applies at the complete drive level.

- RoHS‑aligned materials/processes in many cases for GE electronic spares.

- Manufactured under ISO 9001 quality systems at the OEM level.

- Warranty: 12 months (365 days) against functional defects under normal operation.

A maintenance lead on a strip mill told us a PCCA swap cleared intermittent “start permit” drops tied to a drifting bridge feedback. If you can send the cabinet nameplate and a clear photo of your DS200PCCAG1ACB label, we’ll confirm compatibility, reserve stock, and schedule shipment around your maintenance window.

Reviews

There are no reviews yet.