Description

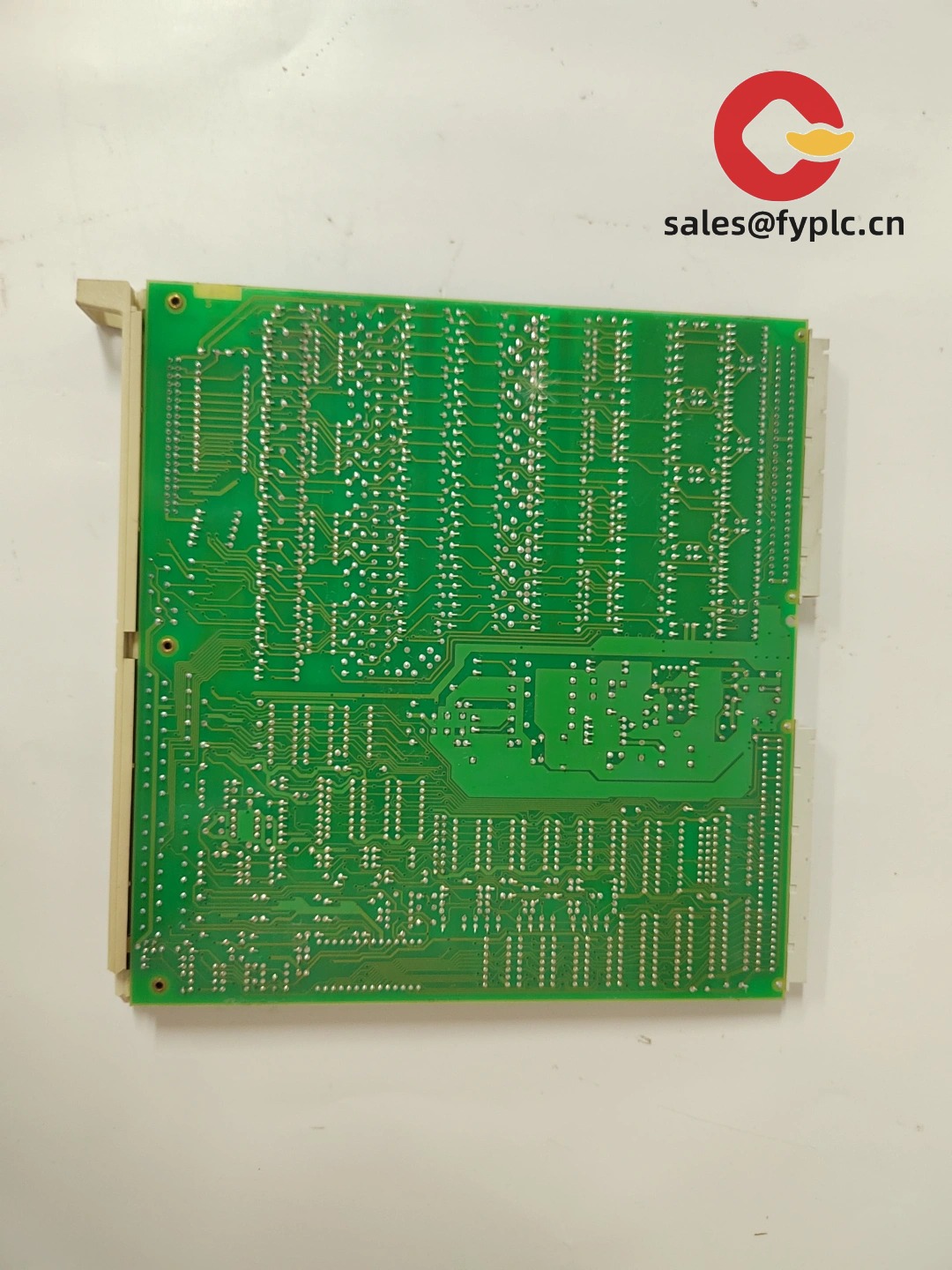

ABB DSAI130D (3BSE003127R1) – S800 I/O Analog Input Module for 4–20 mA Process Signals

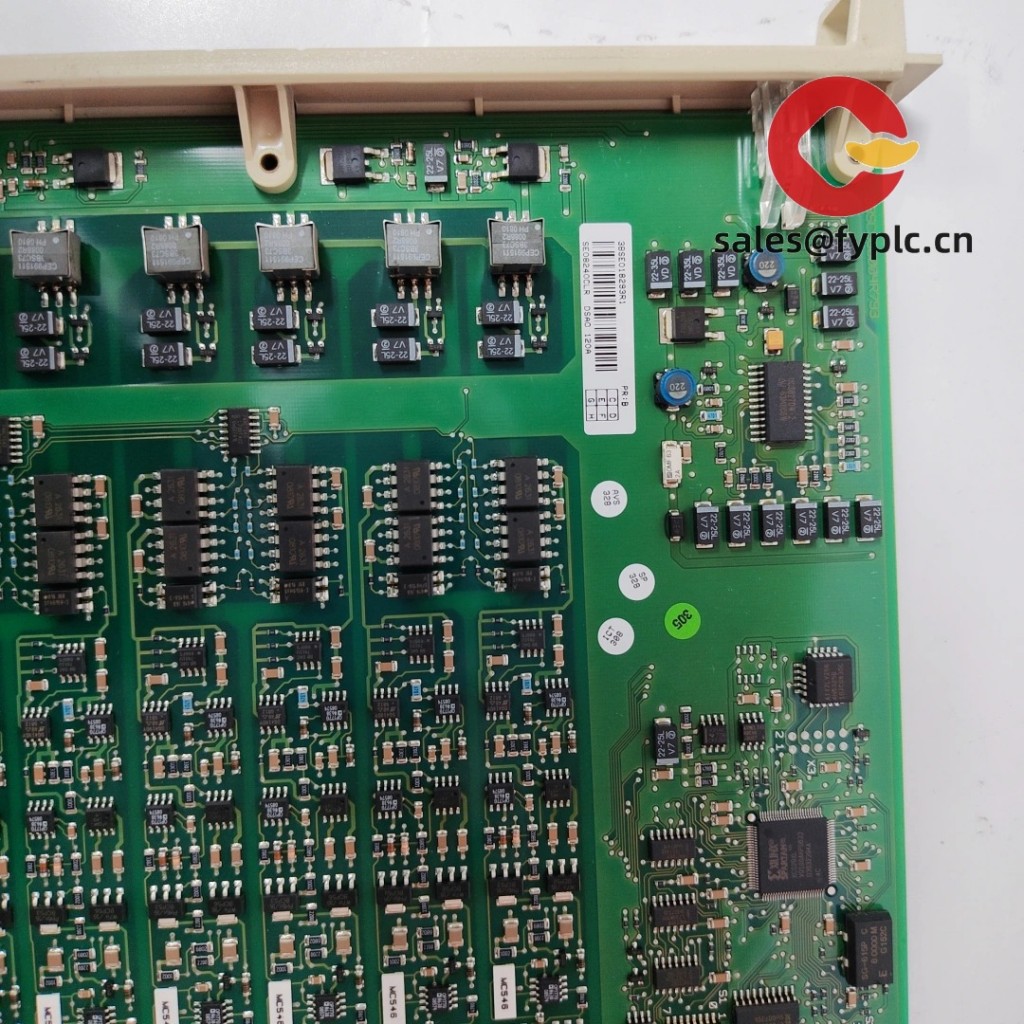

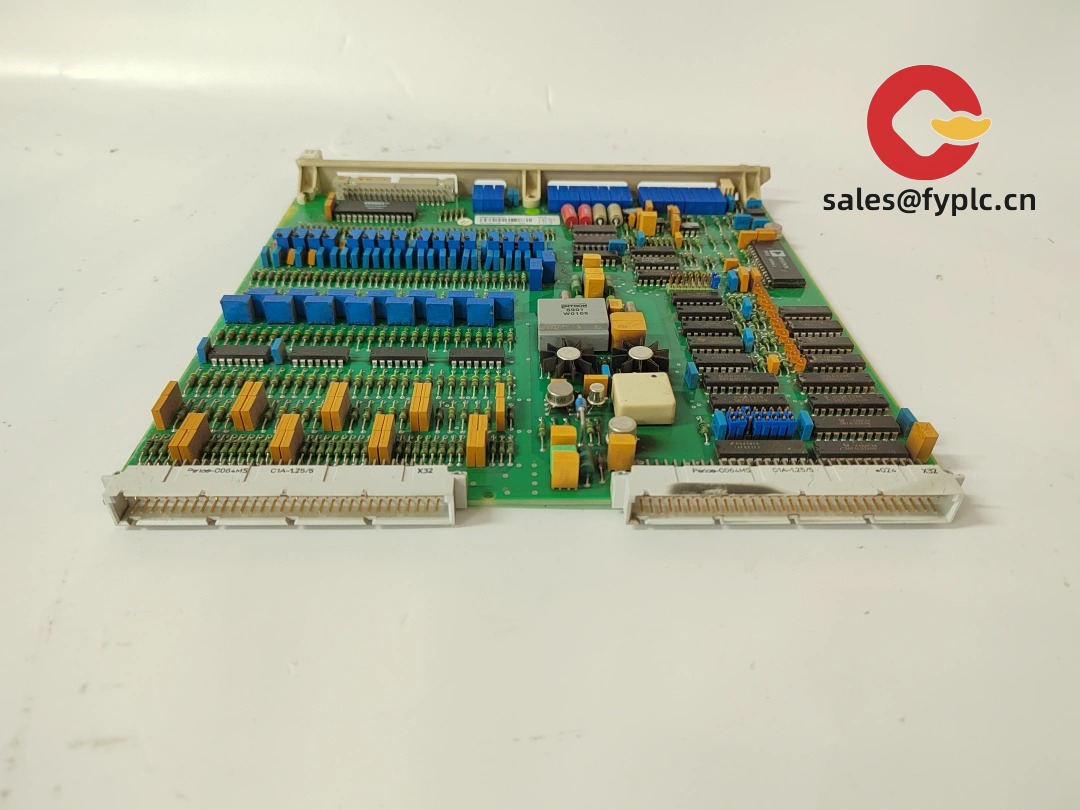

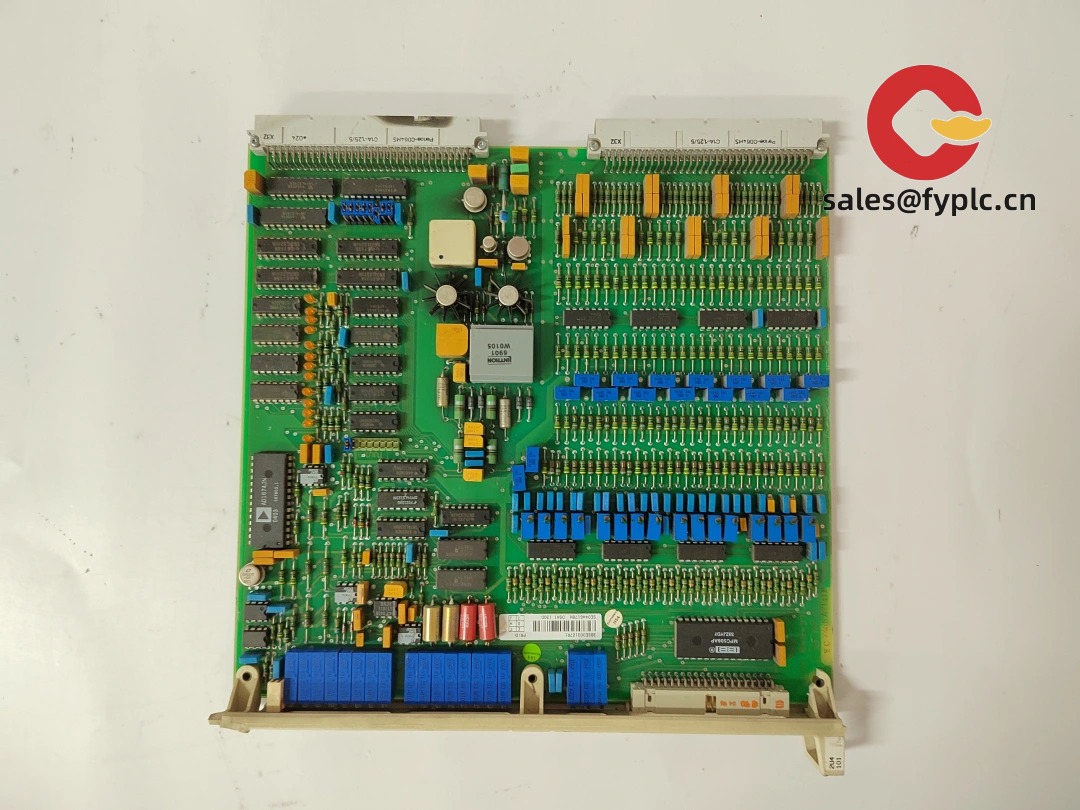

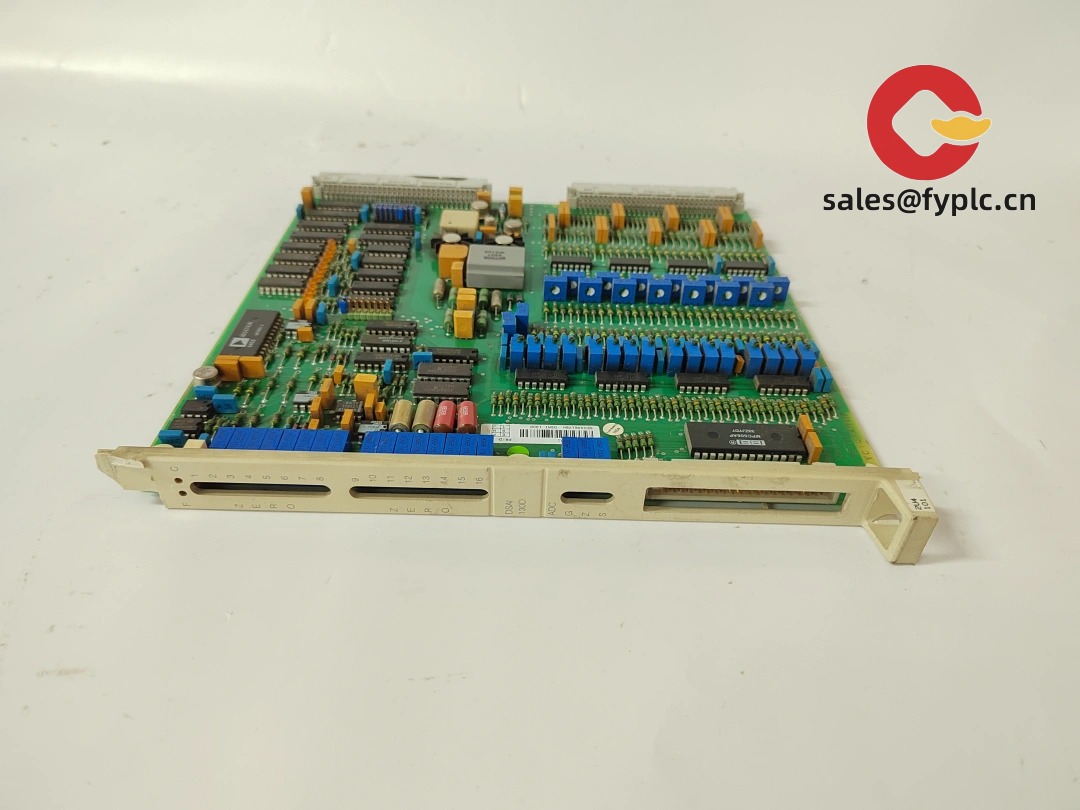

ABB’s DSAI130D, order code 3BSE003127R1, is an S800 I/O analog input module that brings plant 4–20 mA process signals into your control system with predictable accuracy. From my experience, it’s a straightforward way to expand or replace AI capacity on AC 800M-based systems without touching the field wiring routes. You might notice the familiar S800 plug-in form—slide it into the termination unit, let the ModuleBus take care of power and data, and you’re back online with minimal disruption.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx / UPS / DHL

- Compatibility check: Share a photo of the existing S800 rack/termination unit model and this module’s label—it typically speeds up confirmation and avoids returns.

Key Features

- S800 analog inputs – Designed for multi‑channel process inputs, typically 4–20 mA signals from transmitters and positioners.

- Plug‑in replacement – Drop‑in on the S800 termination unit; ModuleBus handles power and data so wiring stays undisturbed in most cases.

- Channel‑wise diagnostics – Helps maintenance pinpoint bad loops or open circuits faster during a short outage.

- Flexible scaling – Engineering units and range handling done in the controller; the module feeds clean raw values to the CPU.

- Lifecycle friendly – A practical spare for brownfield S800 racks where uptime matters more than wholesale upgrades.

Technical Specifications

| Brand / Model | ABB DSAI130D (Order code: 3BSE003127R1), S800 I/O series |

| HS Code | 8538.90 (Parts suitable for electrical control apparatus) |

| Power Requirements | Powered from S800 ModuleBus via termination unit (24 VDC system supply), low power consumption |

| Operating Temperature | Typically 0…55 °C in a ventilated, non‑condensing control cabinet |

| Signal Input/Output Types | Analog inputs, multi‑channel current loops (e.g., 4–20 mA). Exact ranges and per‑channel options depend on D revision settings. |

| Communication Interfaces | S800 ModuleBus (via TU8xx termination unit) to the system controller (e.g., AC 800M) |

| Installation Method | Plug‑in module on S800 TU8xx termination unit, DIN‑rail mounted rack segment |

| Dimensions & Weight | S800 standard compact module; lightweight form factor (see ABB datasheet for exact values) |

Application Fields

Typical across process automation with ABB S800 I/O: pulp & paper steam loops, chemical dosing skids, metals line utilities, water & wastewater plants, and OEM machinery skids. A common scenario is a noisy or drifting loop on an older rack—dropping in a fresh DSAI130D generally stabilizes readings without changing the TU or controller program.

Advantages & Value for Procurement

- Reliability – Restores stable analog measurements, reducing false alarms and control hunting.

- Compatibility – Native to S800 racks; we can verify TU model and ModuleBus details to ensure a clean fit.

- Cost control – Module‑level maintenance is typically far cheaper than a slice/rack migration or system retrofit.

- Low downtime – Plug‑in mechanics make changeouts quick during a short planned stop.

- Technical support – Guidance on channel scaling, loop checks, and addressing so commissioning stays tidy.

Installation & Maintenance

- Cabinet environment – Mount on S800 TU in a clean, dry, ventilated enclosure; ambient 0…55 °C, non‑condensing.

- Safety & isolation – Isolate 24 VDC supply to the rack; lockout/tagout per site rules before handling modules.

- ESD precautions – Use a wrist strap; handle by module edges and avoid touching the connector blades.

- Loop wiring – Verify loop polarity and shield termination at the TU; confirm grounded vs. floating loop strategy.

- Commissioning checks – Calibrate ranges in the controller, simulate 4–20 mA, and confirm scaling/alarms per channel.

- Routine care – Periodic loop integrity checks, clean dust from the rack, and review diagnostics for channels trending to limits.

Quality & Certifications

- Used within CE‑marked ABB automation systems; the module is part of the certified assembly.

- UL/cUL recognition typically at the system level for S800 assemblies.

- RoHS‑aligned components in most cases for ABB electronic modules.

- Manufactured under ISO 9001 quality systems at the OEM level.

- Warranty: 12 months (365 days) against functional defects under normal use.

Related / Supporting Components

From my experience, DSAI130D is commonly paired with S800 termination units like TU810V1 / TU812V1 / TU814, ModuleBus power feed TB810, and AC 800M controllers via CI854/CI851 communication. Share your rack type and TU model and we’ll suggest matching parts so the swap stays truly plug‑and‑play.

A maintenance lead at a water plant told us a fresh DSAI130D stopped random level spikes on two tanks—no wiring changes, just a module swap and a quick scale check. If you can send a photo of your TU part number and the DSAI label, we’ll lock compatibility, reserve stock, and align shipment with your maintenance window.

Reviews

There are no reviews yet.