Description

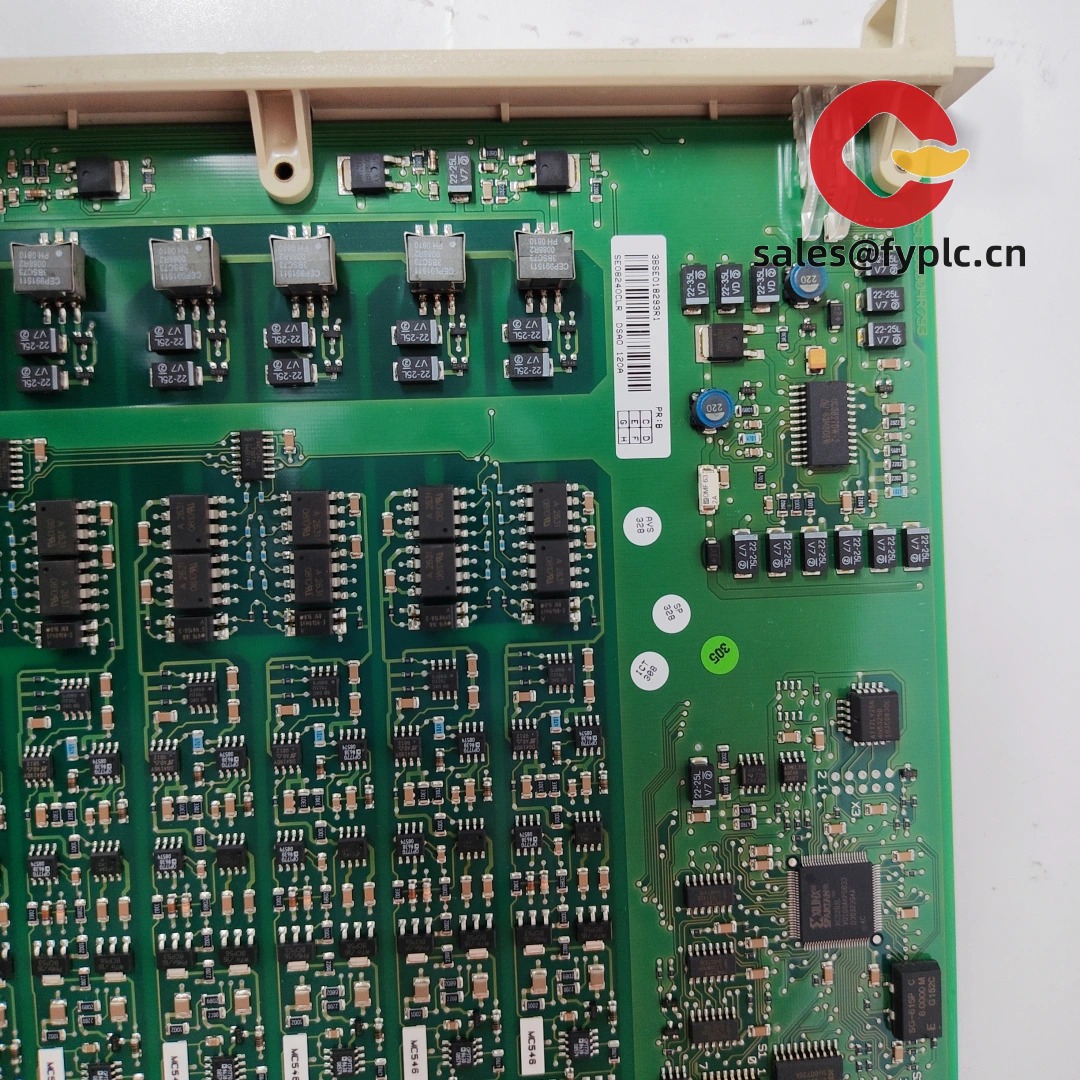

ABB DSAO120A (3BSE018293R1) – S800 I/O Analog Output Module for 4–20 mA Control Loops

ABB’s DSAO120A, order code 3BSE018293R1, is an S800 I/O analog output module designed for driving 4–20 mA actuators and references in process control. From my experience, it’s the go‑to spare when you need to restore clean AO signals to valves, VFD speed references, dampers, or dosing pumps without touching field wiring. You might notice the familiar S800 plug‑in format—slide it onto the TU8xx termination unit, let the ModuleBus power/data connect, and commissioning stays tidy.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx / UPS / DHL

- Pre‑check: Share a photo of your S800 termination unit (TU model) and this module’s label—typically speeds up compatibility confirmation.

Key Features

- 4–20 mA analog outputs – Suited for valve positioners, VFD speed/torque references, and actuator drives.

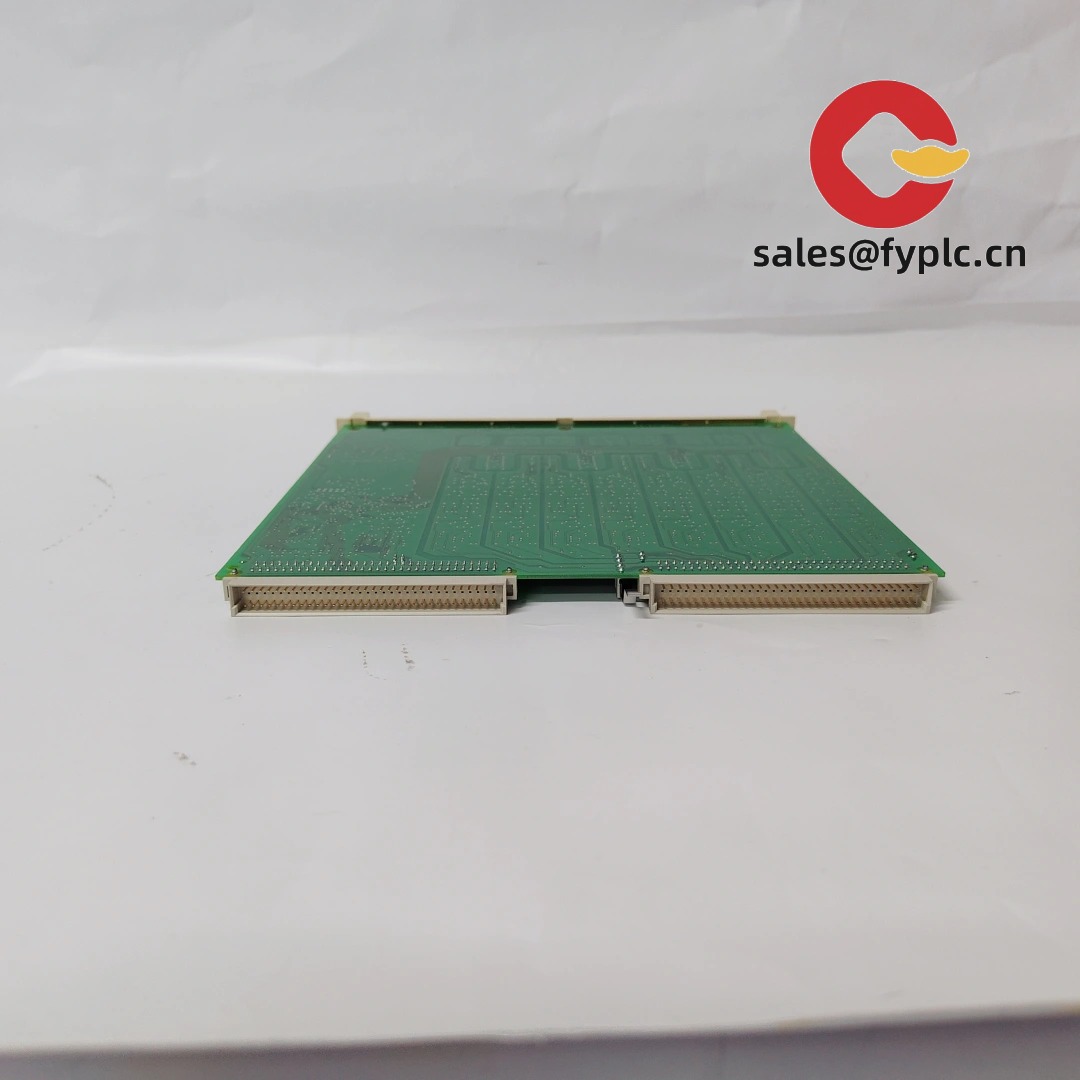

- S800 plug‑in form – Drop‑in on TU8xx termination units; ModuleBus handles power and data, so field wiring stays undisturbed.

- Predictable performance – Delivers stable loop currents that typically reduce hunting and nuisance alarms.

- Maintenance‑friendly – Clear labeling and handle‑and‑insert mechanics keep swaps fast during short outages.

- Lifecycle fit – Ideal for brownfield S800 expansions or one‑for‑one replacements to avoid a larger retrofit.

Technical Specifications

| Brand / Model | ABB DSAO120A (Order code: 3BSE018293R1), S800 I/O series |

| HS Code | 8538.90 (Parts suitable for electrical control apparatus) |

| Power Requirements | Powered via S800 ModuleBus through TU8xx termination unit (24 VDC system supply), low power consumption |

| Operating Temperature | Typically 0…55 °C in a ventilated, non‑condensing control cabinet |

| Signal Output Types | Analog outputs, current loop 4–20 mA (multi‑channel module; exact channel count per ABB datasheet) |

| Communication Interfaces | S800 ModuleBus via TU8xx (to AC 800M or compatible controllers) |

| Installation Method | Plug‑in module on S800 TU8xx termination unit, DIN‑rail mounted rack segment |

Application Fields

Widely used in S800‑based systems for process control: pulp & paper steam valve trims, chemical dosing skids, VFD speed setpoints on metals lines, HVAC dampers, and water & wastewater plants. A typical case is an aging AO module causing drifting valve positions—swapping in DSAO120A usually restores steady outputs without changing the TU or controller logic.

Advantages & Value

- Reliability – Stabilizes loop outputs so process variables settle faster and alarms drop off.

- Compatibility – Native S800 form factor; we can match TU model and rack details so fit is right the first time.

- Cost savings – Module‑level maintenance is typically far cheaper than migrating slices or retrofitting a rack.

- Low downtime – Plug‑in swap keeps the maintenance window short and predictable.

- Technical support – Help with loop loading limits, scaling, and post‑swap verification to keep commissioning smooth.

Installation & Maintenance

- Cabinet environment – Mount on an S800 TU in a clean, dry, ventilated enclosure; ambient 0…55 °C, non‑condensing.

- Safety & isolation – Isolate the 24 VDC rack supply; follow site lockout/tagout before handling modules.

- ESD handling – Use a wrist strap; handle by module edges and keep connectors clean.

- Loop wiring – Confirm loop polarity, shield termination at the TU, and total loop resistance within source limits.

- Commissioning – Simulate 4–20 mA, verify scaling and output limits per channel, and check valve/VFD response.

- Routine care – Periodically review diagnostics, clean dust from the rack, and trend outputs for early signs of load issues.

Quality & Certifications

- Used within CE‑marked ABB automation systems; the module forms part of the certified assembly.

- UL/cUL recognition typically at the system level for S800 I/O.

- RoHS‑aligned electronic components in many cases for ABB modules.

- Manufactured under ISO 9001 quality systems at the OEM level.

- Warranty: 12 months (365 days) against functional defects under normal operation.

One thing I appreciate is how often a straight DSAO swap calms a wandering valve loop. If you can share your TU model (e.g., TU810/TU812/TU814) and a clear photo of the DSAO120A label, we’ll lock compatibility, reserve stock, and align shipment with your maintenance window.

Reviews

There are no reviews yet.