Description

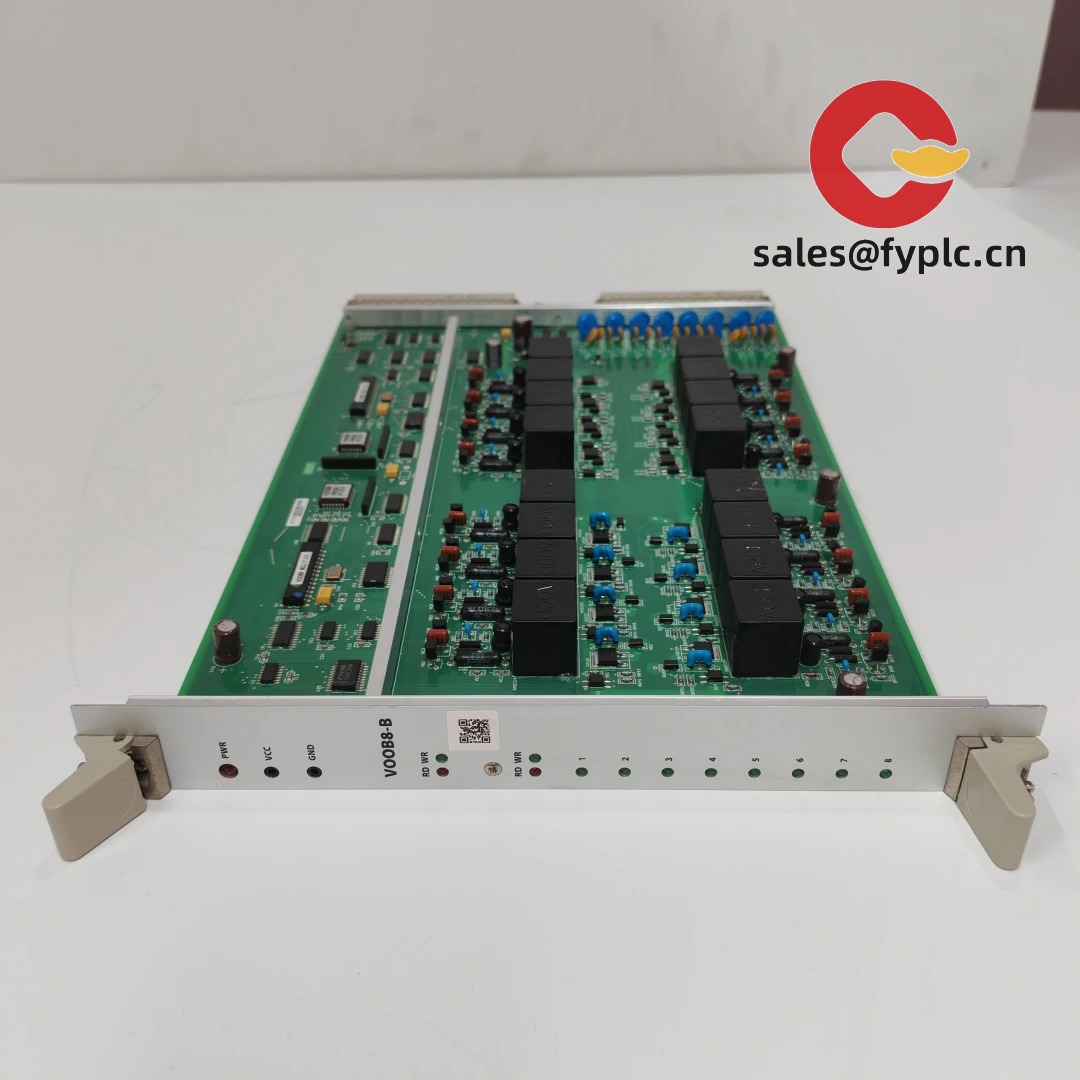

OEM VOOB8-B-12004-106-04-VER-1.0.0 – 8‑Channel Industrial I/O Module for Compact Machine Control

The VOOB8-B-12004-106-04-VER-1.0.0 is a compact, DIN‑rail mounted I/O block designed to add reliable digital points to PLC and edge‑controller projects without the bulk of a full rack system. From my experience, it fits best where you need robust 24 VDC digital I/O, quick Modbus integration, and a tidy footprint inside crowded panels. One thing I appreciate is how predictable it behaves on RS‑485 networks—typically plug-and-run with standard Modbus RTU addressing and response timing.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery options: FedEx, UPS, DHL

- Every unit is function-tested before dispatch; ESD-safe packing as standard

Key Features

- 8 digital I/O channels – Channels can be mapped as inputs or outputs for flexible point assignments in many cases.

- 24 VDC field signals – Suited for standard industrial sensors, relays, solenoids, and indicator stacks.

- RS‑485 Modbus RTU – Easy integration with PLCs, HMIs, and IIoT gateways; typically 1200–115200 bps.

- Rugged, compact housing – DIN‑rail friendly, with clear channel labeling and status LEDs to speed up commissioning.

- Electrical isolation – Bus-to-I/O isolation helps reduce noise coupling in mixed-signal cabinets.

- Safe outputs – Transistor outputs with short-circuit protection; practical for repetitive actuator duty cycles.

- Versioned hardware – VER‑1.0.0 build consistency makes spares planning and documentation straightforward.

Technical Specifications

The specs below reflect the common configuration for VOOB8-B-12004-106-04-VER-1.0.0. If you’re integrating into a tight panel, I can share a dimensional drawing before you freeze your layout.

| Brand / Model | OEM / VOOB8-B-12004-106-04-VER-1.0.0 |

| HS Code | 853710 (Boards, panels, consoles for electric control, ≤1000 V) |

| Power Requirements | 24 VDC nominal (9–30 VDC), ≤3 W typical |

| Dimensions & Weight | Approx. 128 × 90 × 32 mm; ~0.30 kg |

| Operating Temperature | -20 to +60 °C; 5–95% RH, non‑condensing |

| Signal Input/Output Types | 8x configurable digital I/O (24 VDC). Inputs: 24 V logic, debounce filter. Outputs: transistor (sourcing), up to 0.5 A/channel, 2 A total, short‑circuit protection. |

| Communication Interfaces | RS‑485 (Modbus RTU), 2‑wire half‑duplex; 1200–115200 bps; up to 247 slave ID range |

| Isolation & Protection | Bus‑to‑I/O isolation; reverse‑polarity and transient protection on power input; IP20 |

| Installation Method | 35 mm DIN‑rail (EN 60715) or panel mount; detachable screw terminals |

| Status Indication | Power and per‑channel LEDs for quick diagnostics |

Application Fields

You might notice that this module naturally slots into discrete control tasks where response speed and wiring simplicity matter:

- Packaging and labeling lines – sensor aggregation and actuator output blocks next to conveyors

- Machine tools & metalworking – door interlocks, lube pump control, stack lights

- Material handling – diverters, photoeyes, and stop gates over RS‑485 trunks

- Process skids – valve/solenoid control with simple Modbus mapping to the main PLC

- Building & utilities – fan starters, damper position signals, and alarm annunciation

A packaging OEM told me they shaved about 40 minutes off commissioning by using the per‑channel LEDs during loop checks—no laptop needed to spot miswires.

Advantages & Value

- Reliable, stable supply – Versioned hardware keeps spares identical and reduces re‑qualification overhead.

- Easy interoperability – Standard Modbus RTU works with most PLCs, HMIs, and data loggers without custom drivers.

- Lower installed cost – Fewer backplane parts and shorter field wiring typically mean less time in the panel.

- Serviceability – Clear labeling and detachable terminals make swaps fast when uptime is critical.

- Support when you need it – Pre‑shipment testing and responsive technical help through installation and start‑up.

Installation & Maintenance

For best results, mount the unit in an enclosed industrial cabinet with adequate ventilation. Keep high‑voltage and high‑current cabling separated from RS‑485 and signal runs.

- Cabinet & mounting – 35 mm DIN‑rail or panel; allow at least 20 mm clearance on top/bottom for airflow.

- Power & grounding – 24 VDC SELV/PELV supply; tie COM to cabinet ground at a single point to minimize noise.

- Wiring – Use 0.5–1.5 mm² stranded wire; torque per terminal per datasheet; label I/O to match the Modbus map.

- RS‑485 bus – Shielded twisted pair, 120 Ω termination at the ends, biasing as required; daisy‑chain topology.

- Safety – De‑energize before wiring; verify polarity; observe ESD handling procedures.

- Routine checks – Inspect terminal tightness quarterly, remove dust with dry air, and review any event logs. If your unit supports field‑upgradable firmware, keep it aligned with your validated version.

Quality & Certifications

- CE compliant; EMC performance suitable for industrial environments

- RoHS compliant materials

- Manufactured under ISO 9001 quality management systems

- Standard warranty: 365 days

Commonly Paired Accessories

- 24 VDC power supply – Mean Well DR‑60‑24 or HDR‑60‑24 for compact DIN‑rail power

- DIN‑rail end stops – Phoenix Contact E/NS 35 to secure modules during vibration

- RS‑485 terminator/bias kit – 120 Ω terminators and bias resistors for stable multi‑drop networks

- Surge protection – Inline surge suppressors for inductive loads (e.g., solenoids) to extend output life

If you’d like, I can share a sample Modbus register map and a quick‑start wiring note we typically send to OEM teams. It seems to shorten the first article build by a day or so.

Reviews

There are no reviews yet.