Description

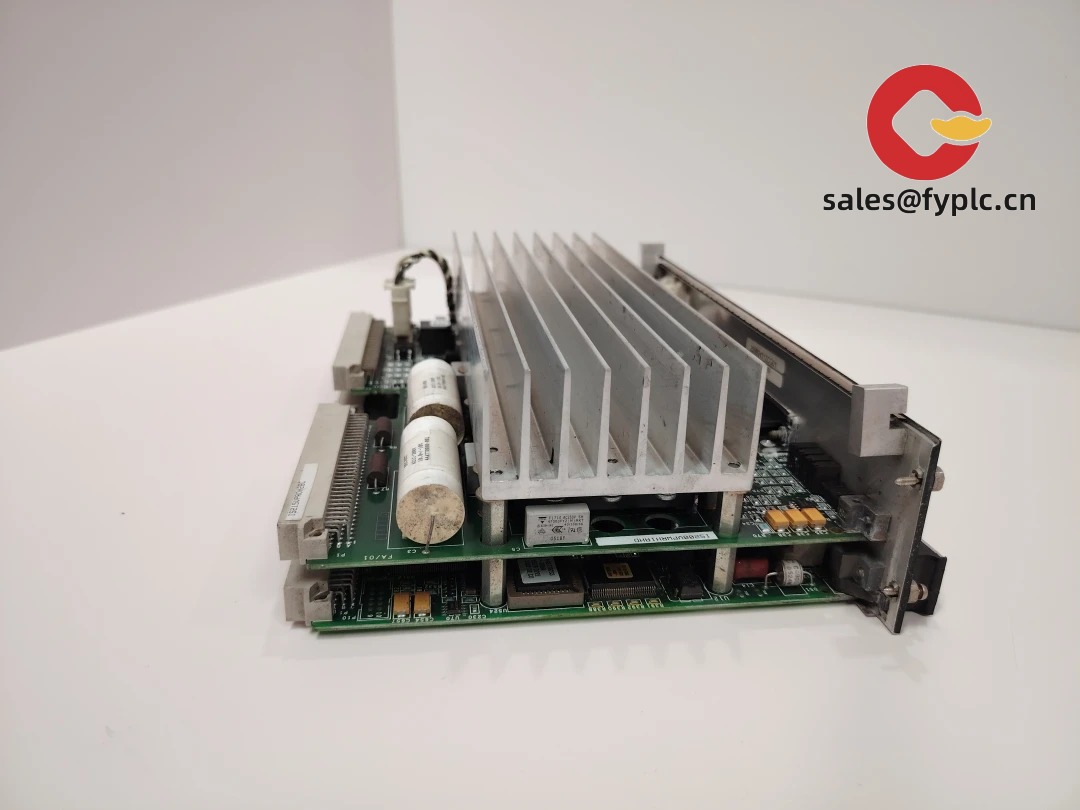

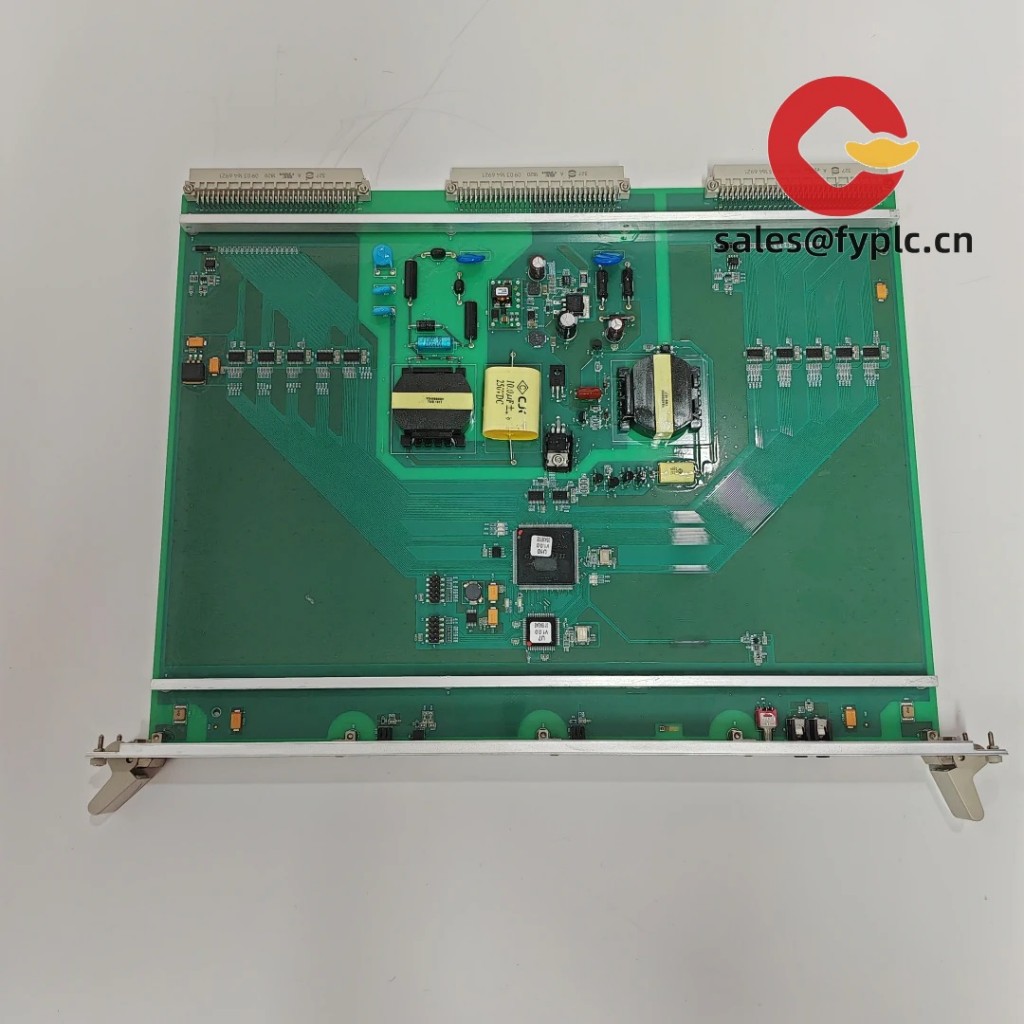

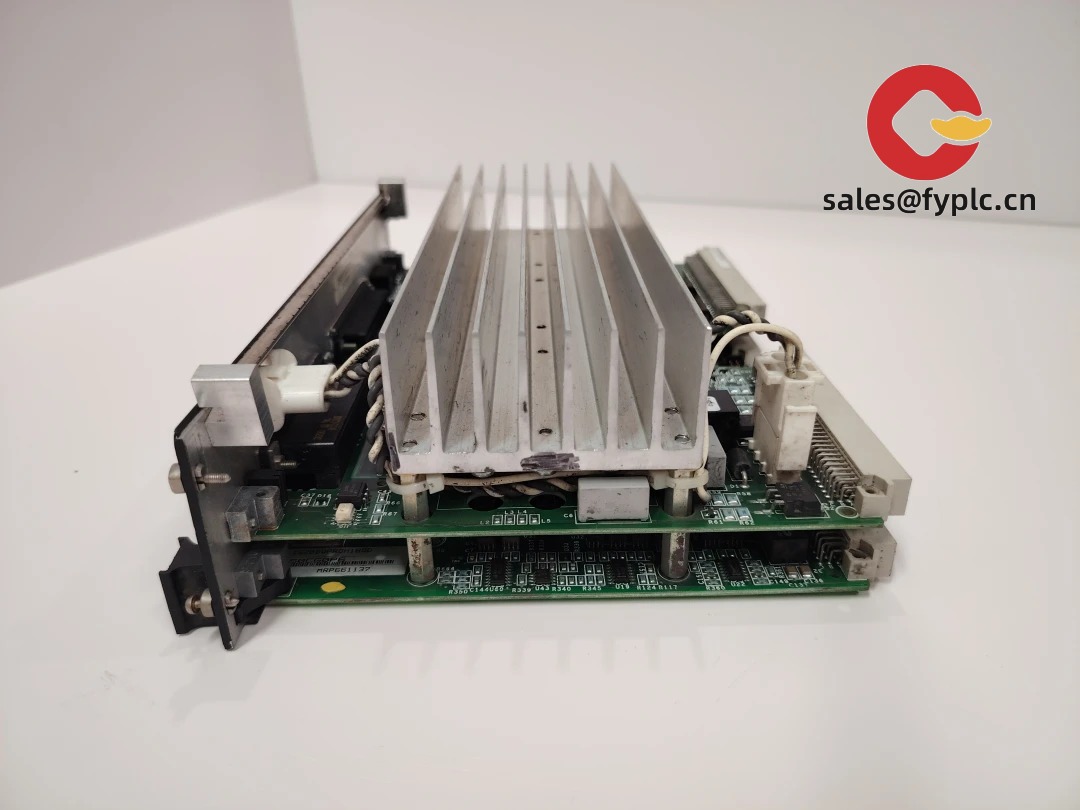

GE IS215VPROH2BC – Protection Processor Module for Mark VI/EX2100 Safety and Trip Control

The GE IS215VPROH2BC is a protection processor module typically used in GE Mark VI and EX2100 platforms to execute fast, deterministic protection logic and coordinate trip commands through associated terminal boards. From my experience, plants rely on VPRO variants where high-integrity shutdown, overspeed protection, or generator protection needs to be handled independently of general sequencing logic. It seems to be the go-to board when you want dedicated, hardware-centric protection with continuous self-diagnostics.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Dedicated protection processing – Executes trip and protection logic separately from general control to reduce risk of shared-resource delays.

- Backplane integration – Plugs directly into the GE rack; all signaling handled via the internal bus, so no field wiring on the module face.

- Built-in diagnostics – Continuous self-checks and watchdog monitoring help identify faults early and support safe fallback behavior.

- Redundancy-ready architectures – Often applied in dual or TMR configurations where high availability and voting are required.

- Event and status reporting – Typically logs key status and trip events to support root-cause analysis and audit trails.

- Revision H2/B-C hardware/firmware line – The H2 hardware with B/C revisions is commonly used to match specific rack builds and firmware baselines.

Technical Specifications

| Brand / Model | GE IS215VPROH2BC |

| HS Code | 8538.90 (Parts suitable for industrial control apparatus) |

| Power Requirements | Backplane powered; typically 5 VDC and auxiliary rails supplied by the rack; no external power input |

| Dimensions & Weight | VME-style plug-in module (approx. 6U Eurocard format); weight typically < 0.8 kg |

| Operating Temperature | 0 to +60 °C (typical for control cabinet environments) |

| Signal Input/Output Types | Internal digital control/status via rack backplane; trip command interfaces realized through associated terminal boards (no direct field I/O on the module) |

| Communication Interfaces | System backplane bus; service access and diagnostics via the host controller tools |

| Installation Method | Plug-in module; slides into rack guides and secures with captive screws; ESD protection required during handling |

Application Fields

You’ll typically see the IS215VPROH2BC in high-integrity applications where a fast, deterministic trip path matters:

- Gas and steam turbine protection (overspeed, critical limit violations)

- Generator protection coordination within EX2100 excitation systems

- Compressor trains and large drive protection in oil & gas installations

- Process units requiring independent trip logic separate from general DCS control

Advantages & Procurement Value

- Reliability by design – Protection logic stays isolated from non-critical tasks, helping keep trip paths deterministic.

- Form/fit compatibility – Designed for GE Mark VI/EX2100 racks, minimizing retrofit work and wiring changes.

- Lifecycle support – H2/B-C revisions are commonly paired with mature firmware baselines, which in many cases simplifies site qualification.

- Inventory flexibility – Faster availability can help reduce outage risk and shorten MTTR during unplanned events.

Installation & Maintenance

- Cabinet standards – Mount in a clean, ventilated control cabinet meeting the GE rack requirements; maintain airflow around the rack.

- ESD and handling – Use wrist straps and antistatic packaging; avoid touching connector edges and components.

- Wiring – No field wiring lands on the module; verify terminal boards and backplane connectors are fully seated and free of debris.

- Firmware alignment – Match hardware/firmware revisions to the site’s validated configuration; keep a backup of the running image and parameter set.

- Routine checks – Review diagnostic logs, confirm watchdog status, and perform periodic functional trip tests during scheduled outages.

- Cleaning – Light dust removal with dry, oil-free air; if conformal-coated, avoid solvents.

Quality & Certifications

- Typically conforms to CE and UL for industrial control equipment

- Manufacturing and QA commonly aligned with ISO 9001 processes

- RoHS considerations apply to many production runs; verify by serial and revision

- Manufacturer’s limited warranty; sales warranty provided: 365 days

Related / Supporting Components

In most cases the IS215VPROH2BC is deployed with GE rack power supplies and trip/termination boards. Typical pairings include:

- GE Mark VI / EX2100 racks – Provide the backplane power and system bus the VPRO relies on.

- Trip terminal boards – Route the protection processor’s trip signals to field devices and solenoids.

- Controller/processor modules – Coordinate sequence control, while the VPRO focuses on protection logic.

One thing I appreciate is how straightforward swaps can be when the rack, terminal boards, and firmware baseline are already aligned—site teams often report a quick return-to-service. A maintenance lead at a combined-cycle plant mentioned their VPRO changeout plus validation took just a single shift after pre-checks.

Reviews

There are no reviews yet.