Description

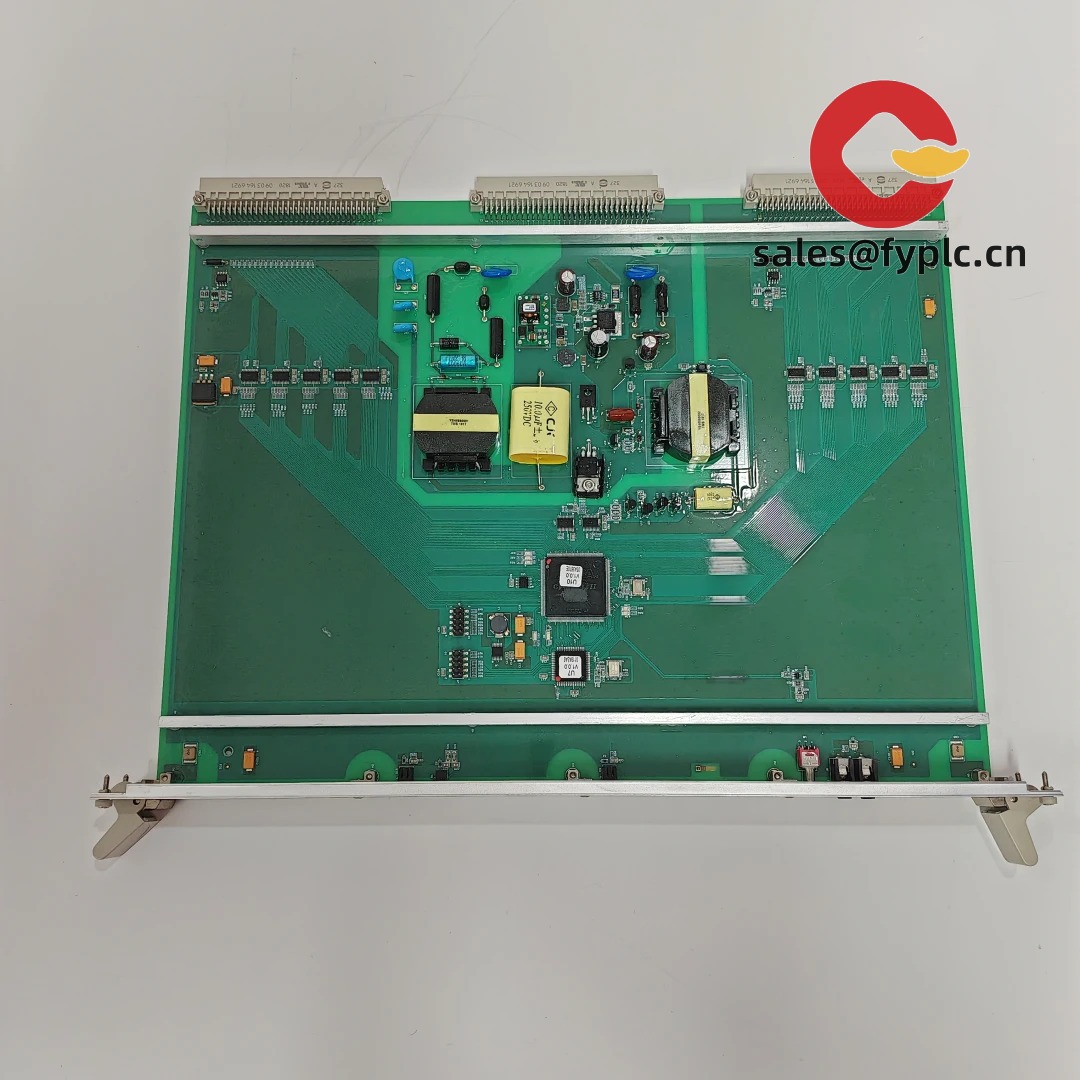

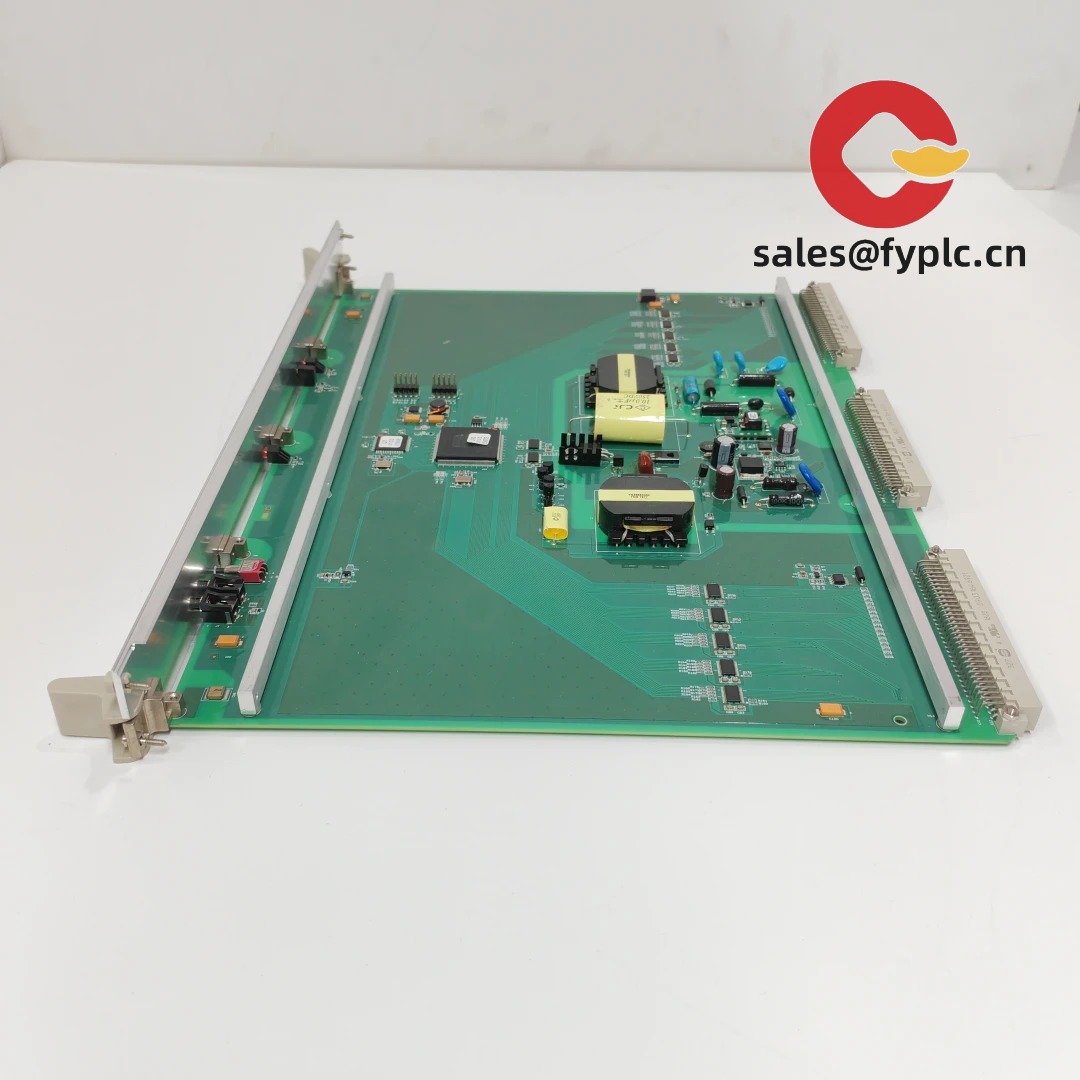

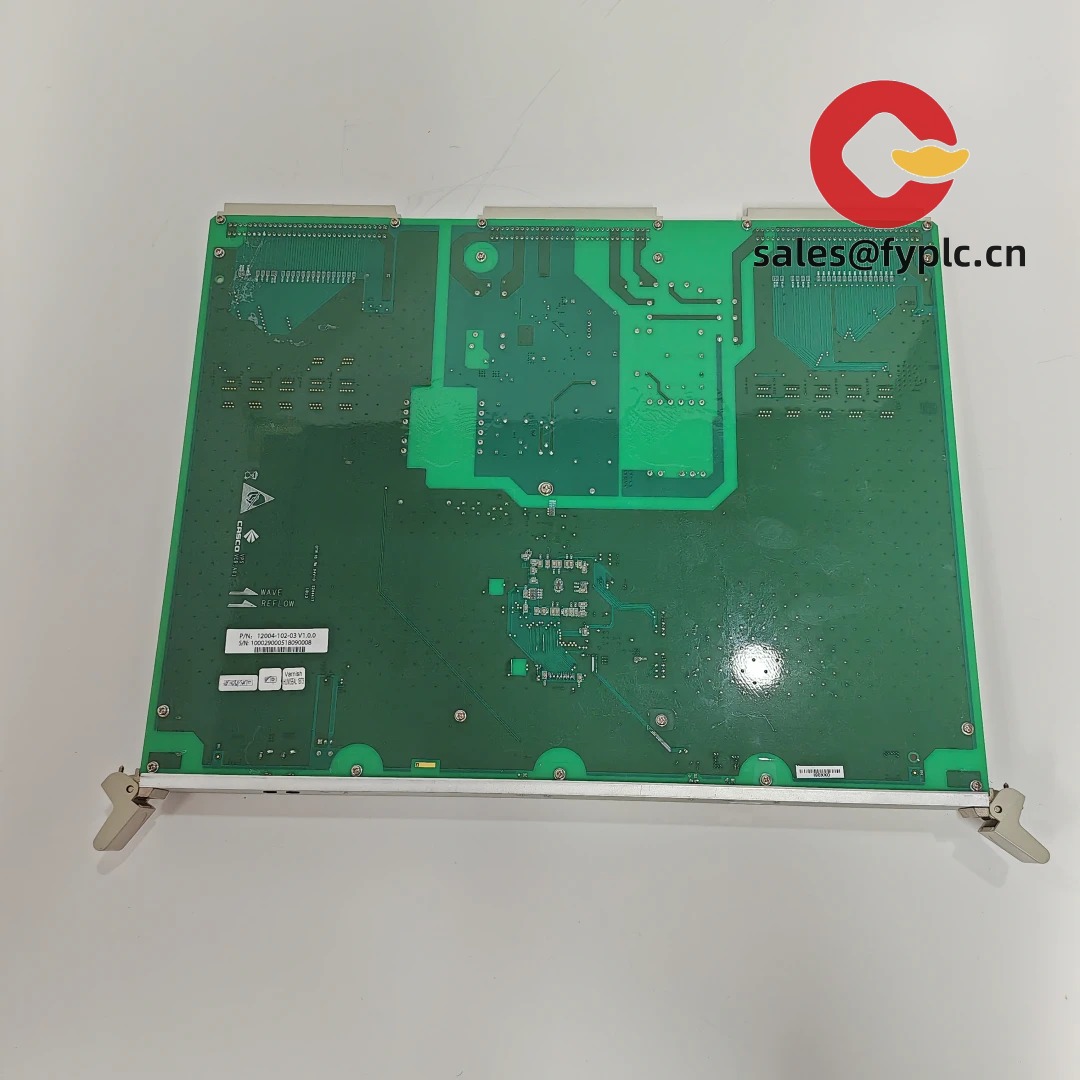

VPS Series – VPS_12004-102-03_V1.0.0 industrial protection/monitoring module for control cabinets

The VPS_12004-102-03_V1.0.0 is a compact industrial module typically used for condition monitoring and protection logic in control panels. From my experience, this VPS variant slots in neatly on a DIN rail, takes a stable 24 VDC supply, and bridges sensors to plant controls through simple relays or Modbus. You might notice that the version tag “V1.0.0” aligns with a stable, baseline firmware—ideal for replacement projects where you want consistent behavior across units.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

One thing I appreciate is the predictability—most replacement orders ship quickly, and we pre-check firmware revision against your requirement to avoid mismatches onsite.

Key Features

- 24 VDC control power – Designed for standard cabinet supplies; typically tolerant to 18–30 VDC.

- Mixed signal I/O – Accepts common industrial sensor signals and exposes clean relay outputs for alarms or trips.

- RS‑485 (Modbus RTU) integration – In many cases used for data collection or remote parameter checks from the PLC/SCADA side.

- DIN‑rail friendly footprint – Saves panel space and speeds up swap‑outs during maintenance.

- Firmware V1.0.0 – Stable baseline behavior; good choice for like‑for‑like replacements across a fleet.

- Service/update port – Typically a front‑access service interface for configuration or firmware refresh.

- Field‑proven reliability – Teams report fewer nuisance trips compared to mixed third‑party modules.

Technical Specifications

| Brand / Model | VPS Series / VPS_12004-102-03_V1.0.0 |

| HS Code | 8538.90 (Parts for electrical control apparatus; final classification may vary by jurisdiction) |

| Power Requirements | 24 VDC nominal (typ. 18–30 VDC), ≤10 W in most cases |

| Operating Temperature | -20°C to +60°C (typical control cabinet environment) |

| Signal Input/Output Types | Analog inputs (e.g., 4–20 mA), digital inputs (24 VDC), relay outputs (alarm/trip) |

| Communication Interfaces | RS‑485 (Modbus RTU); service/configuration port for firmware update |

| Installation Method | DIN‑rail mounting; panel mount option in many cabinets |

| Dimensions & Weight | Compact DIN‑rail module footprint; lightweight (<0.5 kg) |

| Firmware | V1.0.0 (field‑stable baseline) |

Application Fields

This model is commonly adopted in rotating equipment protection (pumps, fans, compressors), conveying lines, and general machine safeguarding where sensor inputs must trigger deterministic alarms or shutdowns. A typical setup is: 4–20 mA vibration or temperature into the module, alarm thresholds set via software, dry‑contact relays wired to the PLC E‑stop loop, and RS‑485 into SCADA for trending. A maintenance lead from a food plant told us, “After swapping in the VPS_12004-102-03_V1.0.0, our conveyor stopped throwing nuisance faults during washdown, which saved us several unplanned stops per week.”

Advantages & Value

- Reliability in real cabinets – Appears to be quite tolerant to electrical noise when properly grounded and shielded.

- Compatibility – Works smoothly with mainstream PLCs over RS‑485/Modbus; relay outputs drop into existing alarm circuits.

- Cost control – Reduces nuisance trips and technician call‑outs, which in many cases pays back faster than expected.

- Support & stocking – We align firmware revision and terminal layout before shipping so your onsite install is plug‑and‑play.

Installation & Maintenance

Panel/cabinet: Mount on 35 mm DIN rail inside a ventilated cabinet (IP54 or better recommended). Allow ~50 mm clearance for airflow.

Power & grounding: 24 VDC supply via a dedicated, fused feed. Bond PE ground to the cabinet ground bar. Keep analog and power wiring separated.

Wiring: Use shielded twisted pairs for 4–20 mA signals; terminate RS‑485 with 120 Ω at the bus ends; maintain common reference to avoid ground loops.

Safety: De‑energize before servicing. Verify alarm/trip logic in a safe test mode prior to putting the machine back into service.

Routine maintenance: Quarterly check of terminal tightness, dust removal with dry air, verify alarm thresholds, and—if applicable—apply non‑disruptive firmware updates via the service port.

Quality & Certifications

- CE compliance for EMC and LVD (typical for this class of control modules)

- RoHS conformant materials

- Manufactured under ISO 9001 quality systems

- Warranty: 365 days

Common Supporting Components

- 24 VDC panel power supply (e.g., 60 W) with DIN‑rail clip

- DIN‑rail end clamps and grounding terminals

- RS‑485 to USB converter for commissioning

- Shielded signal cable (2‑pair, 22 AWG) for analog inputs

Reviews

There are no reviews yet.