Description

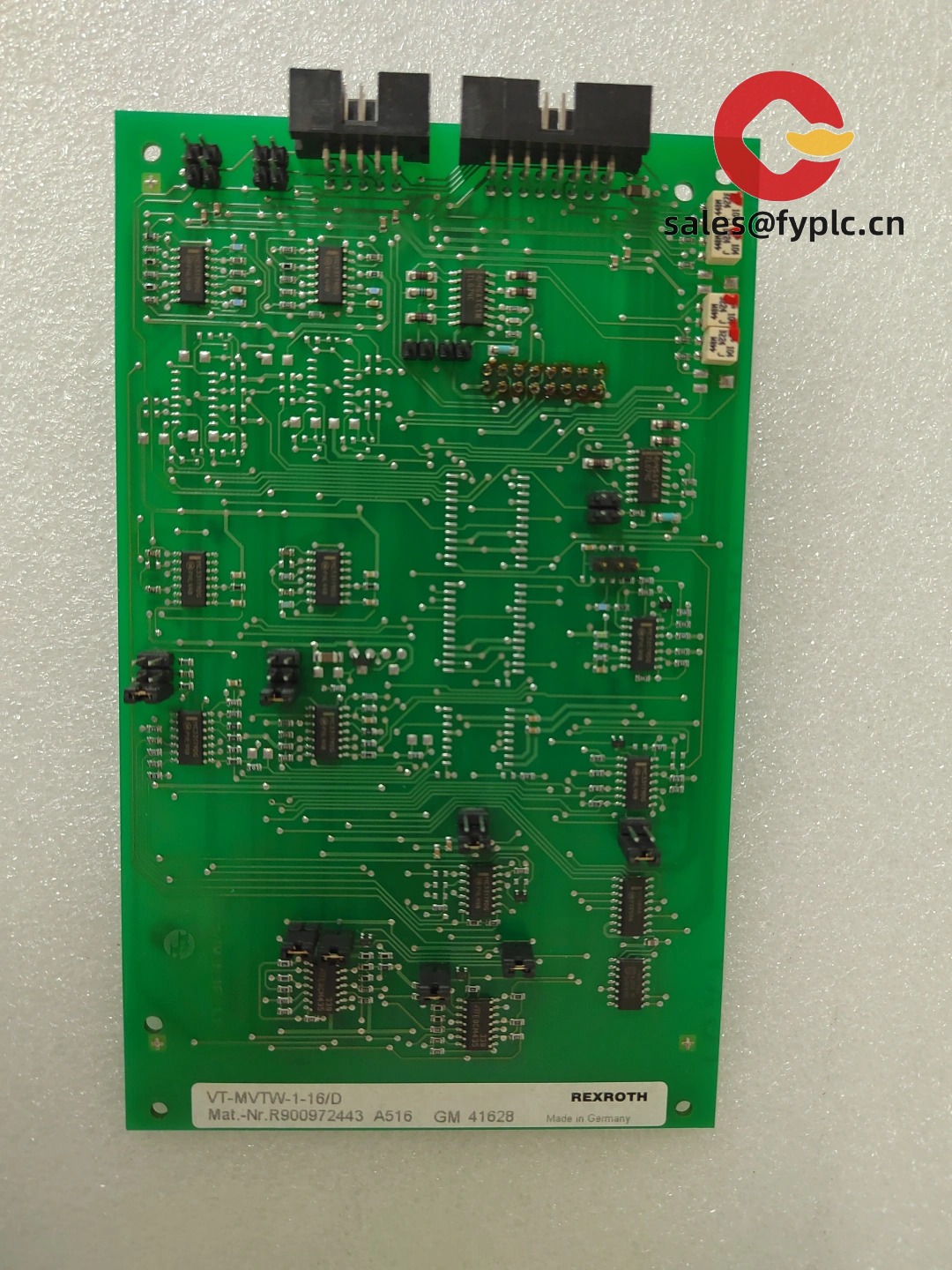

Bosch Rexroth VT-MVTW-1-16-D – LVDT/RVDT Signal Conditioner for Precise Position Feedback in Hydraulic Systems

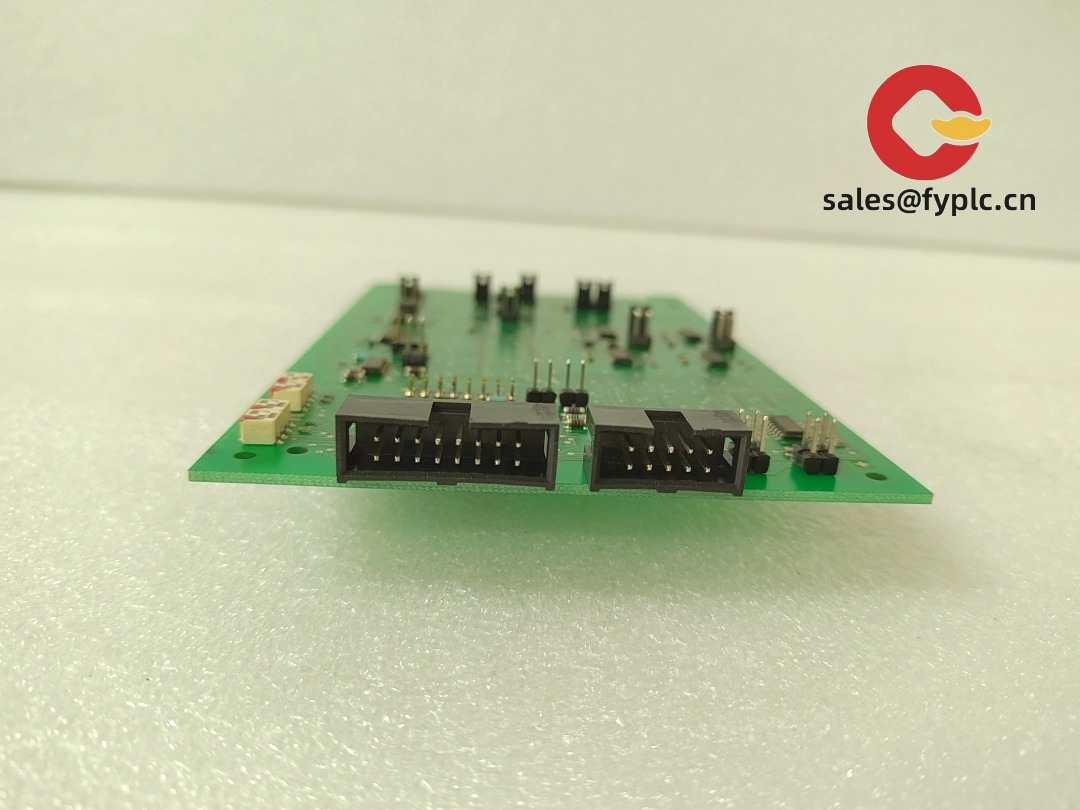

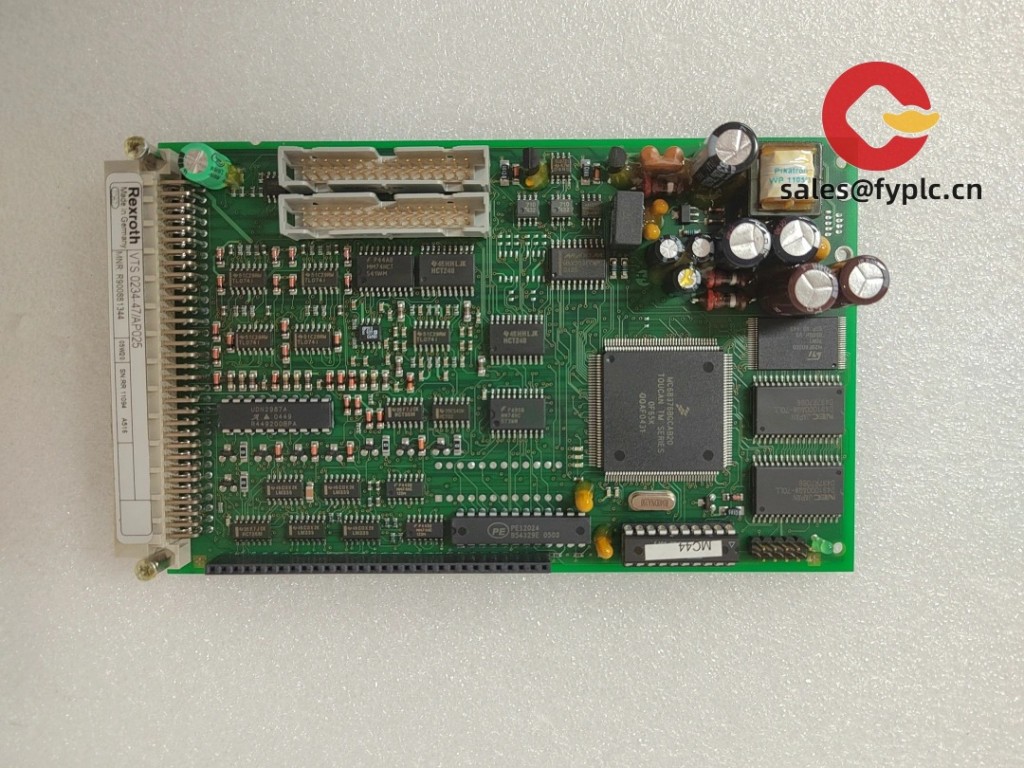

The Bosch Rexroth VT-MVTW-1-16-D is a measuring value transducer that conditions LVDT/RVDT displacement signals and converts them into clean, standardized analog outputs for closed-loop motion and position control. From my experience, it’s typically chosen for hydraulic cylinders, presses, and test benches where stable position feedback is non‑negotiable. You might notice that it slots easily into existing control cabinets and plays nicely with most PLC/drive platforms thanks to selectable voltage or current outputs.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week when in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

- Pre‑shipment checks: Visual inspection and basic functional verification are performed before dispatch

Key Features

- LVDT/RVDT signal conditioning – Excites the transducer and demodulates the return signal for stable, low‑noise feedback.

- Standardized analog outputs – Typically supports 0–10 V and 4–20 mA, making integration with common PLCs and motion controllers straightforward.

- Zero/Span and filtering – Front‑end adjustments help you dial out mechanical offsets and smooth high‑frequency noise in many cases.

- 24 VDC industrial supply – Runs on the standard machine supply, keeping your cabinet power architecture simple.

- Robust stability – Designed for continuous operation in hydraulic environments where vibration and electrical noise are common.

- Fail‑safe behavior – When sensor wiring issues occur, the output typically indicates a fault condition to protect your process.

- Flexible scaling – Easy to match cylinder stroke or actuator travel, reducing PLC math and commissioning time.

Technical Specifications

| Brand / Model | Bosch Rexroth VT-MVTW-1-16-D |

| Product Type | LVDT/RVDT signal conditioner (measuring value transducer) |

| HS Code | 8543.70 (Electrical apparatus with individual functions, n.e.s.) |

| Power Requirements | 24 VDC nominal (±10%), typical consumption < 8 W |

| Operating Temperature | 0 to +50 °C (typical cabinet conditions) |

| Signal Input / Output | Input: LVDT/RVDT displacement sensor; Output: 0–10 V and/or 4–20 mA (selectable/ordered variant) |

| Communication Interfaces | Analog module; no fieldbus required for operation |

| Installation Method | Control cabinet mounting; the -D variant is typically used on DIN rail (EN 60715) |

Application Fields

This model fits well in hydraulic and electromechanical systems where accurate linear or rotary position feedback is required. Typical scenarios:

- Hydraulic cylinder position control on presses, steel machinery, and metallurgical lines

- Plastic injection molding and die‑casting machines requiring consistent mold alignment

- Test rigs and actuator benches needing repeatable displacement measurement

- Servo‑hydraulic positioning on web handling, forming, and motion stages

One maintenance manager told us the VT‑MVTW helped “clean up” an unstable position loop; after enabling mild filtering and re‑scaling, their drift complaints dropped off within a shift.

Advantages & Value

- Reliability in harsh cabinets – Designed for continuous duty near pumps and drives; noise immunity seems to be better than generic conditioners.

- Interoperability – Standard 0–10 V / 4–20 mA outputs make it drop‑in compatible with mainstream PLC/servo brands.

- Commissioning speed – Zero/span and simple scaling trim reduce PLC code edits and cut start‑up hours.

- Total cost – Stabilizing a loop at the conditioner often avoids expensive valve or sensor swaps.

- Support ecosystem – Widely used in hydraulic motion control, so spare parts and know‑how are easier to source.

Installation & Maintenance

- Cabinet & mounting – Install in a ventilated control cabinet; for the -D variant use DIN rail per EN 60715 with end stops to prevent movement.

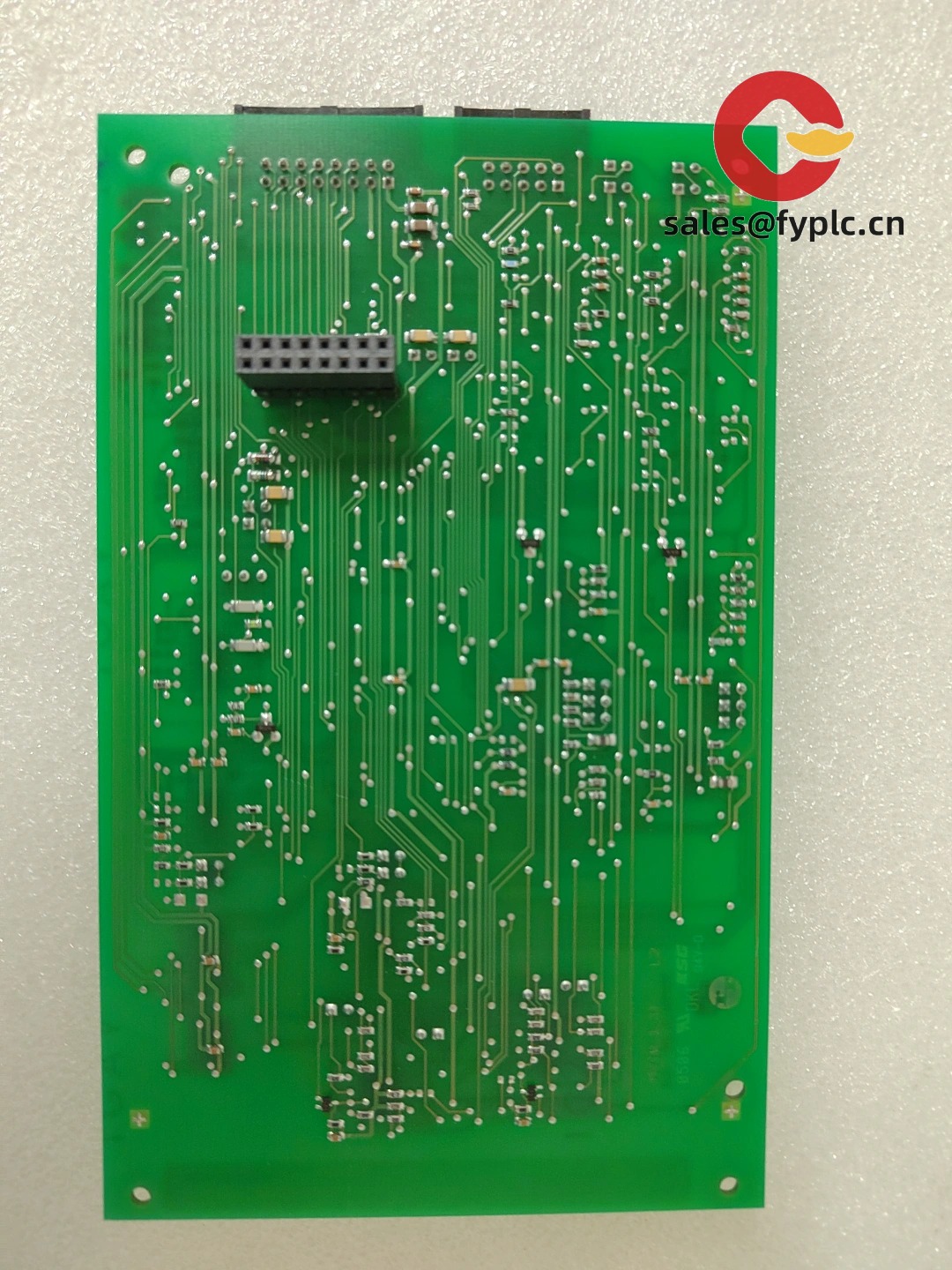

- Power & grounding – Use a regulated 24 VDC supply with proper protective earth; keep sensor returns isolated from power commons where required.

- Wiring – Route LVDT/RVDT leads with twisted, shielded cable; terminate shields at a single point to minimize ground loops.

- Commissioning – Perform sensor nulling, then adjust zero/span. Apply moderate filtering only as needed to avoid adding control lag.

- Routine maintenance – Quarterly connector checks and cleaning; verify output scaling annually or after sensor replacement.

- Firmware – This model is analog; no firmware updates required, which simplifies upkeep.

Quality & Certifications

- CE compliant for industrial control environments

- RoHS compliant components in most cases

- Manufactured under ISO 9001 quality systems (typical for Bosch Rexroth plants)

- Manufacturer’s warranty practices apply; we provide a 365‑day warranty from shipment

Recommended Supporting Components

- Compatible LVDT displacement sensors (industrial 5 kHz to 10 kHz excitation types)

- Shielded multi‑core signal cable with proper drain wire for sensor runs

- 24 VDC industrial power supply with low ripple and overload protection

- Terminal markers and end stops for secure DIN rail mounting

Reviews

There are no reviews yet.