Description

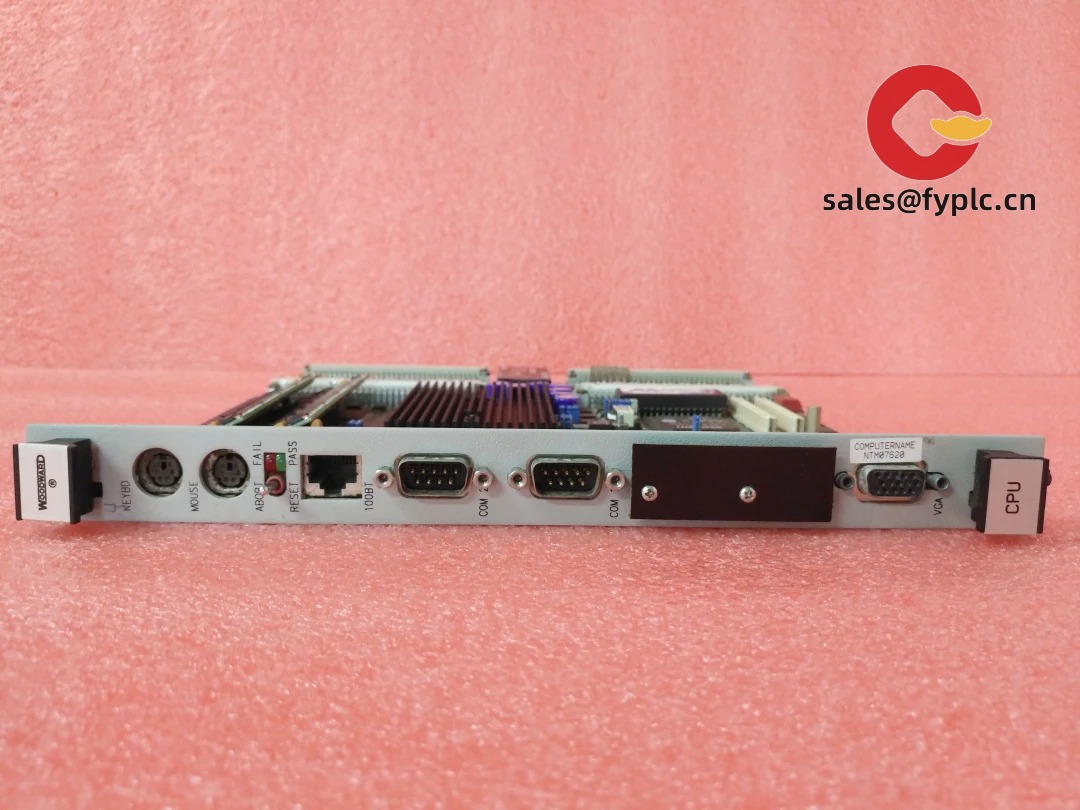

WOODWARD 5466-409 – MicroNet I/O Module for Turbine and Engine Control Racks

The WOODWARD 5466-409 is a plug-in I/O module designed for MicroNet and, in many cases, MicroNet TMR control racks used on industrial turbines, large engines, and compressor trains. From my experience, these modules are selected when a site wants proven, rack-based I/O with strong diagnostics and long-term serviceability. You might notice that it drops straight into the standard MicroNet chassis, with status LEDs on the bezel and backplane-powered operation—no external power wiring on the card itself. It’s a reliable spare or expansion card for plants standardizing on Woodward architectures.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full balance prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- MicroNet rack compatibility – Designed to fit standard WOODWARD MicroNet/MicroNet TMR chassis for fast drop-in replacement or expansion.

- Backplane-powered – Typically powered via the rack backplane (24 VDC nominal at the system level), reducing field wiring clutter.

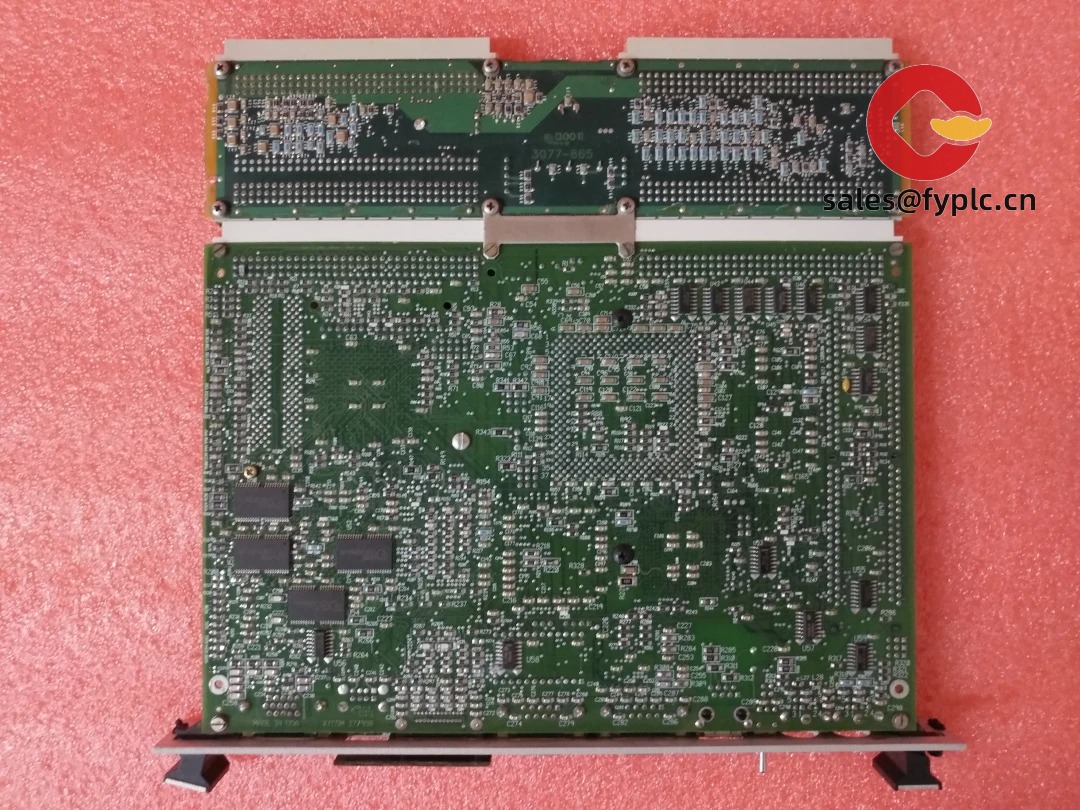

- Industrial-grade build – Conformal-coated PCB and robust connectors help the card stand up to cabinet humidity and vibration.

- Front-panel diagnostics – Status LEDs simplify commissioning and fault tracing during outages.

- Turbine/engine proven – Commonly used in steam and gas turbine packages where continuous operation and fast maintenance matter.

- Service-friendly – Field-replaceable with basic ESD precautions; typically a single-slot module with secure faceplate screws.

Technical Specifications

| Brand / Model | WOODWARD 5466-409 |

| Product Type | MicroNet rack I/O module (industrial control) |

| Compatibility | MicroNet / MicroNet TMR systems (verify slot assignment in your rack BOM) |

| HS Code | 9032.90 (Parts and accessories for automatic regulating or controlling instruments) |

| Power Requirements | Backplane powered (system nominal 24 VDC supply to rack; no external power to the card) |

| Dimensions & Weight | Single-slot plug-in module for MicroNet chassis; typical module weight in the 0.6–0.9 kg range |

| Operating Temperature | Typically 0 to +60 °C inside a ventilated control cabinet |

| Signal Input/Output Types | Module-level I/O via rack/terminal boards; commonly used for field signals in MicroNet systems (confirm exact I/O map for 5466-409 against your project docs) |

| Communication Interfaces | Backplane communication to CPU/Comm modules; front-panel status LEDs (no external comm ports on the card) |

| Installation Method | Plug-in to MicroNet rack; secure faceplate; field wiring through associated terminal/FTM boards |

Application Fields

- Steam and gas turbine control (governor, protection, sequencing)

- Large engine and generator set control in power and marine applications

- Compressor and pump trains in refineries, petrochemical plants, and pipelines

- Balance-of-plant panels where MicroNet racks aggregate field I/O

One thing I appreciate is how these cards simplify outages: technicians can swap the module, check the LEDs, run a quick loopback/field check, and bring the unit back up with minimal schedule risk. A maintenance lead at a combined-cycle site told me the spare 5466-series modules “paid for themselves during a planned outage—less than an hour from replace to verify.”

Advantages & Value

- Reliability – Built for continuous service; typically conformal-coated and designed for cabinet environments.

- Compatibility – Matches MicroNet/MicroNet TMR ecosystems, avoiding rewiring or software rework.

- Lifecycle support – Common spare across many fleets; easier to hold minimum stock.

- Cost control – Reduces downtime and engineering effort during expansion or repairs.

- Technical support – We can help verify slotting, firmware alignment, and commissioning checklists.

Installation & Maintenance

- Cabinet environment – Install in a clean, ventilated control cabinet; maintain ambient typically within 0–60 °C and avoid condensation.

- Mounting – Power down the rack unless your site procedure allows otherwise; observe ESD precautions; seat the module firmly and tighten faceplate screws.

- Wiring – Field wiring terminates on the associated terminal/FTM boards; keep analog and discrete wiring separated and follow shield-ground practices.

- Safety – Lockout/tagout before handling field circuits; verify zero energy and correct card orientation before insertion.

- Routine checks – Periodically inspect connectors, clean dust with dry air, and review diagnostics via front LEDs or system tools.

- Configuration/firmware – After replacement, confirm the I/O assignment and firmware/project revisions match your validated configuration before returning to service.

Quality & Certifications

- Manufacturer’s quality system: typically ISO 9001

- Product compliance: MicroNet systems are CE-marked; individual module markings may vary by production lot

- RoHS/UL/CSA: availability depends on build revision and destination market—can be verified against your serial/part list

- Standard warranty: 365 days from shipment

Supporting Components You May Need

- MicroNet or MicroNet TMR chassis (slot compatibility to be confirmed)

- Associated terminal/field termination modules and cables for your I/O type

- CPU/communications modules (5466-series) if expanding rack capacity

If you share your rack BOM or a photo of the nameplate and slot map, I can quickly confirm whether 5466-409 is the exact match and advise on any terminal board part numbers to complete the install.

Reviews

There are no reviews yet.