Description

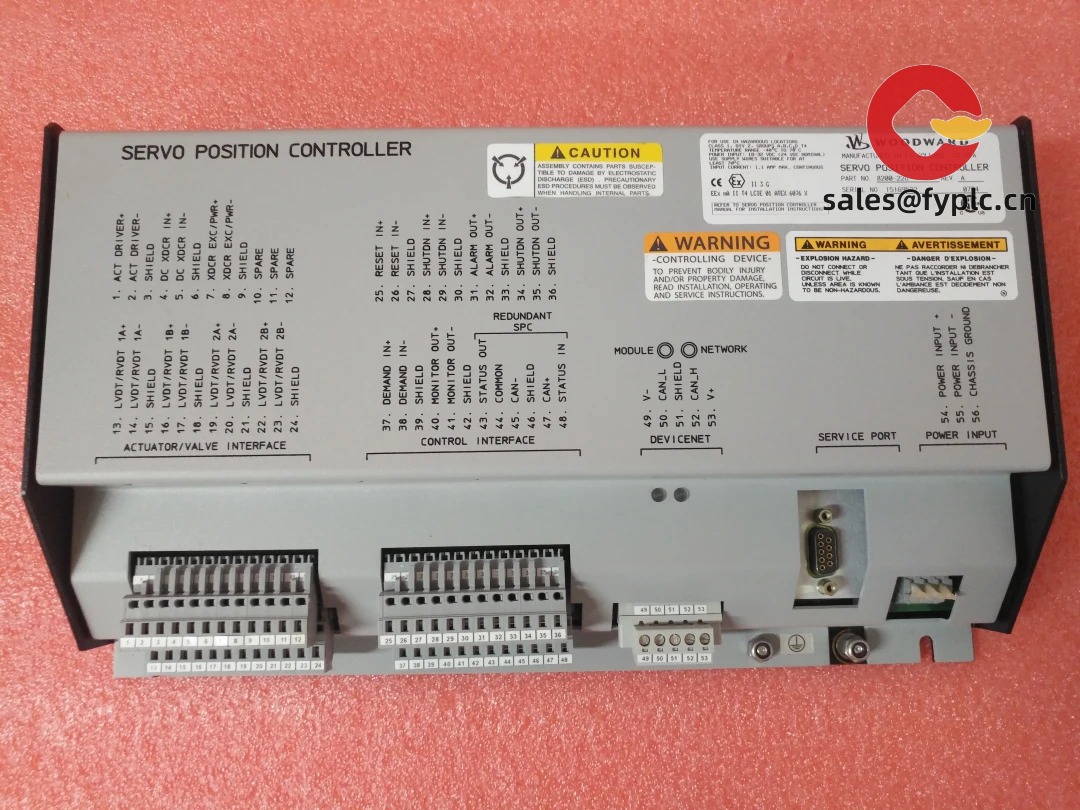

WOODWARD 8200-226 Speed Governor Module for Engine and Turbine Control

The WOODWARD 8200-226 is a proven speed governor module designed for precise engine and turbine control—typically used on gensets, compressors, pumps, and mechanical-drive packages. From my experience, it’s the kind of controller maintenance teams pick when they want dependable speed regulation, straightforward tuning, and compatibility with existing Woodward actuators and MPUs. You might notice that it fits retrofit jobs nicely: analog/discrete I/O, robust 24 Vdc operation, and fail-safe behavior that most plants insist on.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Precise speed control – Uses a magnetic pickup (MPU) signal for stable isochronous or droop regulation in most applications.

- Actuator-ready output – Current-drive output typically compatible with Woodward proportional actuators (EG/EPG and similar).

- Analog & discrete control – Supports remote speed setpoint (e.g., 4–20 mA or low-voltage analog) and raise/lower contacts for field adjust.

- Fail-safe behavior – Designed so loss of speed signal or supply drives to a safe, minimum-fuel condition in most cases.

- Rugged power input – 24 Vdc nominal operation with industrial noise immunity; ideal for cabinet-mounted deployments.

- Load sharing ready – Can be integrated with Woodward load-sharing modules when parallel gensets are required.

- Field-proven hardware tuning – No laptop needed; dedicated trimmers/switches keep commissioning simple and predictable.

Technical Specifications

| Brand / Model | WOODWARD 8200-226 |

| HS Code | 9032.89 (Automatic regulating or controlling instruments and apparatus) |

| Power Requirements | 18–32 Vdc, 24 Vdc nominal; power consumption typically <15 W |

| Operating Temperature | -40°C to +70°C (typical industrial rating) |

| Signal Input / Output Types | • Magnetic Pickup (MPU) speed input • Remote speed/reference input (e.g., 4–20 mA or low-voltage analog) • Raise/Lower discrete inputs for setpoint trim • Actuator current output (proportional), compatible with Woodward actuators • Alarm/Shutdown relay (if equipped) |

| Communication Interfaces | Analog/discrete control; no serial communications on standard builds |

| Installation Method | Panel/chassis mounting inside a control cabinet; screw terminal wiring |

| Dimensions & Weight | Panel-mount module; compact metal enclosure. Typical weight under 2 kg. For exact build-code dimensions, refer to the product datasheet. |

Application Fields

– Gas and diesel gensets—prime and standby power, with or without load sharing.

– Mechanical-drive engines on pumps, compressors, and fans where tight speed control matters.

– Small gas turbines and process units needing stable governor behavior and reliable droop/isochronous modes.

– Marine auxiliary sets where cabinet space is tight yet robustness is non-negotiable.

A maintenance lead at a midstream facility told us the 8200-226 “dropped in” as a replacement for an aging governor and held speed within spec after a quick gain/droop tune—no laptop, no drama.

Advantages & Value

- Reliability that operators trust – Hardware-based control tends to be predictable and resilient against electrical noise.

- Compatibility – Works with common Woodward MPUs and proportional actuators, reducing retrofit risk and onsite rework.

- Commissioning speed – Potentiometer tuning means less time in configuration and faster return-to-service.

- Lifecycle support – Spares and accessories are widely available; documentation is straightforward for most setups.

- Cost control – Minimal software/firmware overhead and simple wiring typically translate to lower installation costs.

Installation & Maintenance

- Cabinet & environment – Mount in a clean, dry control cabinet (NEMA/IP-rated) with adequate ventilation; avoid vibration and heat sources.

- Wiring – Use shielded twisted-pair for MPU and analog references; ground shields at one end only to prevent ground loops. Keep actuator wiring separate from high-voltage runs.

- Power quality – Stabilized 24 Vdc supply; include proper fusing and a dedicated return. Many sites add surge suppression for brownout resilience.

- Tuning – Set gain, reset, and droop gradually. From my experience, small increments and step-load checks prevent hunting.

- Routine checks – Inspect terminal tightness quarterly, verify MPU air-gap, and function-test shutdown/alarm circuits. Cleaning dust from vents/connectors extends life.

- Updates – If your unit includes any configurable options or firmware-dependent features, document current settings and back them up after changes.

Quality & Certifications

- Manufacturer quality system: ISO 9001 (typical for Woodward manufacturing)

- CE compliance for EMC and safety on standard industrial builds

- UL/cUL recognition may apply depending on build code

- RoHS compliance where applicable for industrial exemptions

- Warranty: 12 months (365 days) from delivery

Related/Supporting Components

- Magnetic Pickups (MPU) – Engine speed sensors, various thread sizes and lengths.

- Woodward proportional actuators – EG/EPG series and other proportional electric actuators typically used with this controller.

- Load sharing modules – For parallel gensets requiring kW/VAR control with compatible Woodward devices.

If you’re replacing an existing governor or standardizing across a fleet, the 8200-226 seems to be a safe, low-friction option. Share your current actuator and MPU details, and we’ll confirm wiring and tuning guidance before shipment.

Reviews

There are no reviews yet.