Description

Woodward 8237-1600 – Industrial Governor Control Module for Engine and Turbine Speed Management

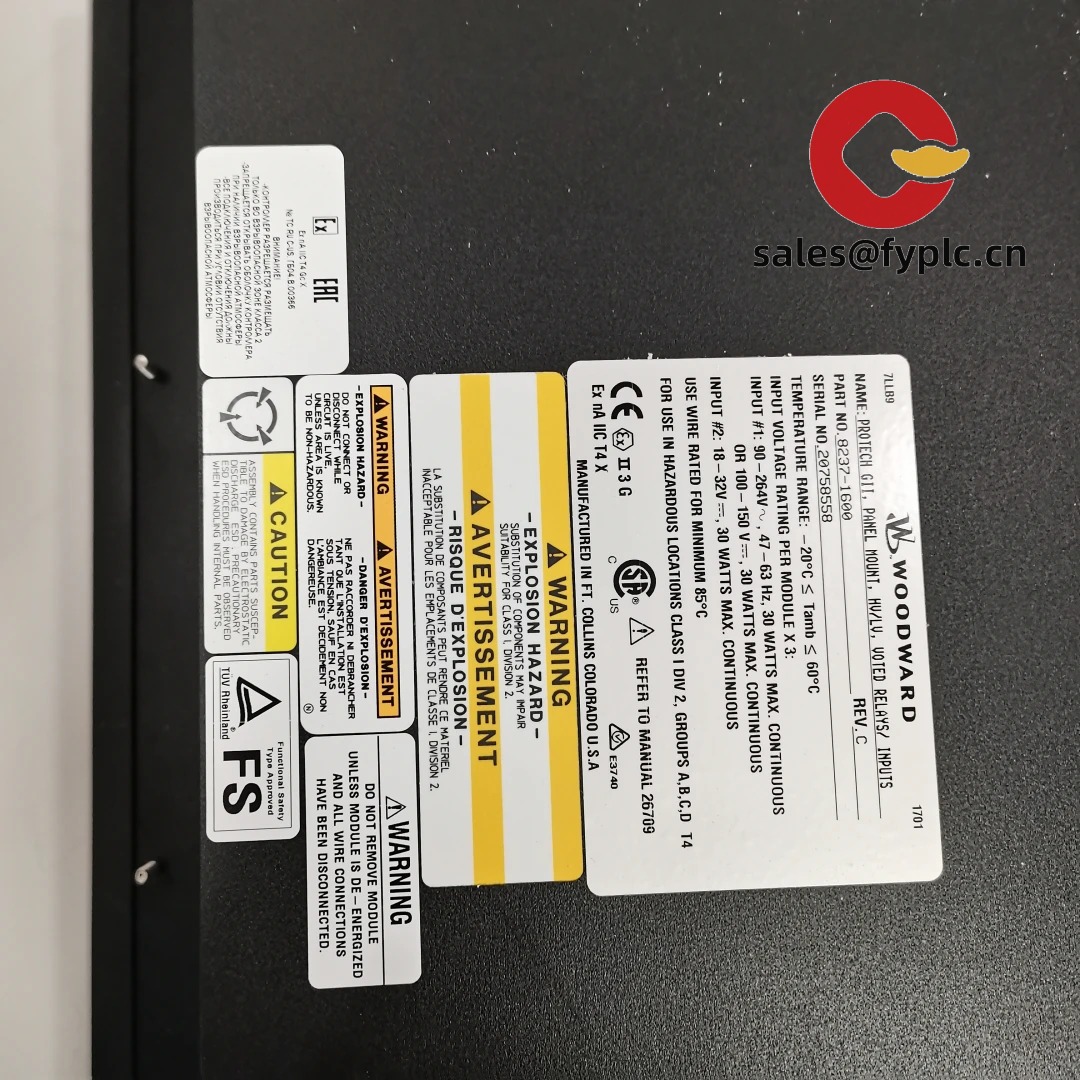

The Woodward 8237-1600 is a factory-designated control module used in many Woodward governor and speed-control assemblies. In most cases, this module functions as part of an engine or small turbine speed regulation system—handling MPU speed pickup signals, driving actuator commands, and coordinating load sharing or protection logic depending on the host system. From my experience, it’s typically supplied as a direct replacement part for installed Woodward panels, making it a practical choice for maintenance teams looking to minimize downtime and avoid re-engineering.

If you’re replacing an in-service unit, match the complete part number and revision on the nameplate. That tends to be the fastest path to “plug-and-run” compatibility without additional tuning.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: In-stock ships in ~1 week; not in stock—no more than one month

- Payment: 50% advance payment; balance due prior to delivery

- Express options: FedEx, UPS, DHL

- Packaging: Anti-static bag + foam + export carton for safe transit

- Traceability: We confirm P/N and revision before shipment to ensure the right fit

Key Features

- Engine/Turbine Speed Control Core – Designed for governor systems, typically handling MPU speed sensing and actuator drive signals for stable RPM control.

- Drop-in Service Part – Commonly supplied as a like-for-like replacement to reduce commissioning effort and avoid wiring changes.

- Industrial 24 VDC Architecture – Works within standard panel power ecosystems, simplifying integration with existing controls and auxiliaries.

- Hardwired I/O – You might notice the focus on analog/digital I/O over fieldbus, which fits many legacy and retrofit projects.

- Rugged Build – Woodward modules are known for dependable operation in generator sets, compressor packages, and small turbine skids.

- Service-Friendly – Clearly labeled terminals and familiar Woodward tuning approach help maintenance techs get through start-up faster.

Technical Specifications

| Brand / Model | Woodward 8237-1600 |

| HS Code | 8537.10 (Control equipment for a voltage ≤ 1000 V) |

| Power Requirements | 24 VDC nominal (typical operating range 18–32 VDC) |

| Operating Temperature | Industrial range; typically -20 to +70 °C (verify per exact revision) |

| Signal Input Types | MPU/gear-tooth speed pickup; 4–20 mA or voltage analog (varies by configuration); discrete dry-contact inputs |

| Signal Output Types | Actuator drive/command output; relay/alarm contacts; analog control output where applicable |

| Communication Interfaces | Hardwired I/O; fieldbus not typical on this part number |

| Installation Method | Panel/cabinet mounting; screw-terminal wiring; follow grounding and shielding practices for MPU runs |

Application Fields

The 8237-1600 is commonly found as a module within Woodward governor panels on:

- Diesel and gas generator sets (prime power and standby)

- Industrial gas engines driving compressors, pumps, and blowers

- Small steam or gas turbines for process drives

- Retrofit and lifecycle replacements in legacy Woodward speed-control systems

A maintenance manager recently shared that swapping this module on a compressor skid restored stable speed within one startup sequence—no field wiring changes, just a quick tuning check. That’s the typical experience when the part number is matched correctly.

Advantages & Value

- Reliability – Woodward hardware is known for long service life in harsh environments; fewer nuisance trips and less time on call-outs.

- Compatibility – Intended as a like-for-like module for existing Woodward systems, which typically avoids panel rewiring.

- Cost Control – A targeted replacement reduces engineering hours and production risk compared to a full system upgrade.

- Technical Support – Clear wiring conventions and established tuning methods help field techs move fast during commissioning.

Installation & Maintenance

- Panel/Cabinet – Install in a clean, dry, ventilated cabinet. Maintain panel depth clearance for wiring bends and heat dissipation.

- Power & Grounding – Use a stable 24 VDC supply with proper grounding. Separate MPU and low-level signal wiring from power conductors.

- Shielding – Shielded twisted pair for MPU and analog runs; ground shields at one end to minimize noise coupling.

- Wiring – Torque terminals per the manual; label conductors for maintenance traceability.

- Safety – Lockout/tagout before handling. Verify zero energy on actuator circuits and alarms before disconnecting.

- Routine Care – Periodic terminal re-torque, connector inspection, dust cleaning with dry air, and verification of governor setpoints after maintenance.

- Firmware/Settings – If your system stores parameter sets, back them up before swap; restore and validate during restart.

Quality & Certifications

- Manufacturer certifications typically include CE and UL/cUL for panel-level systems where this module is installed.

- RoHS conformity is common across modern Woodward control modules; confirm per exact revision if your site requires documentation.

- Standard manufacturer warranty applies; we support a 365-day warranty on this supplied part.

Complementary Components (often paired in the field)

- MPU Speed Sensors – Gear-tooth magnetic pickups for accurate RPM feedback.

- Actuators – Woodward electric or electro-hydraulic actuators (e.g., EG series or ProAct) driven by the governor output.

- 24 VDC Power Conditioning – DIN-rail supplies and surge suppression to keep the control bus clean.

- Panel Accessories – Emergency stop relays, alarm beacons, and interposing relays for field I/O expansion.

Note: The 8237-1600 designation refers to a specific Woodward module configuration. Features and I/O may vary by revision and system context. If you share a photo of the nameplate or your existing panel P/N, I can confirm exact compatibility before shipment.

Reviews

There are no reviews yet.