Description

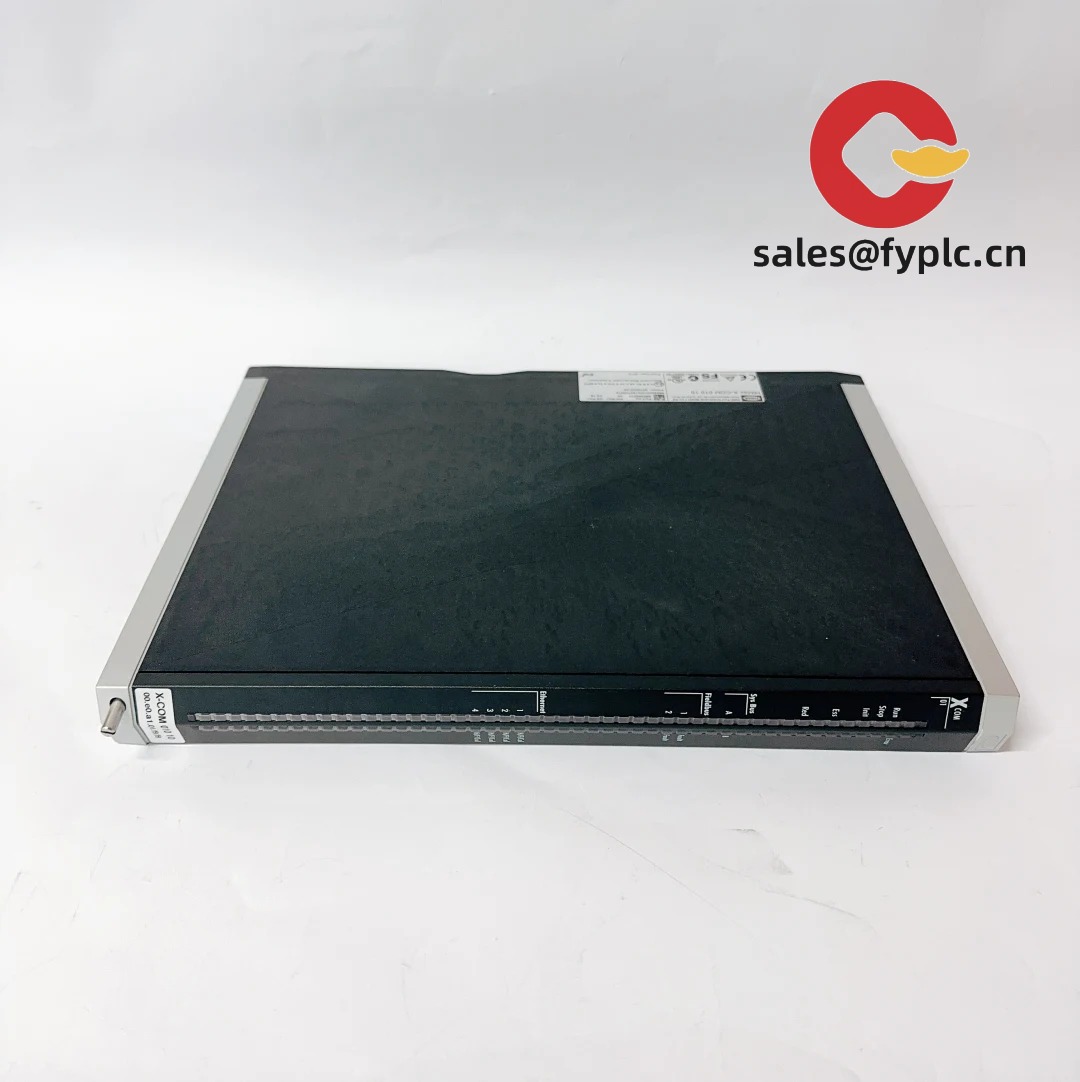

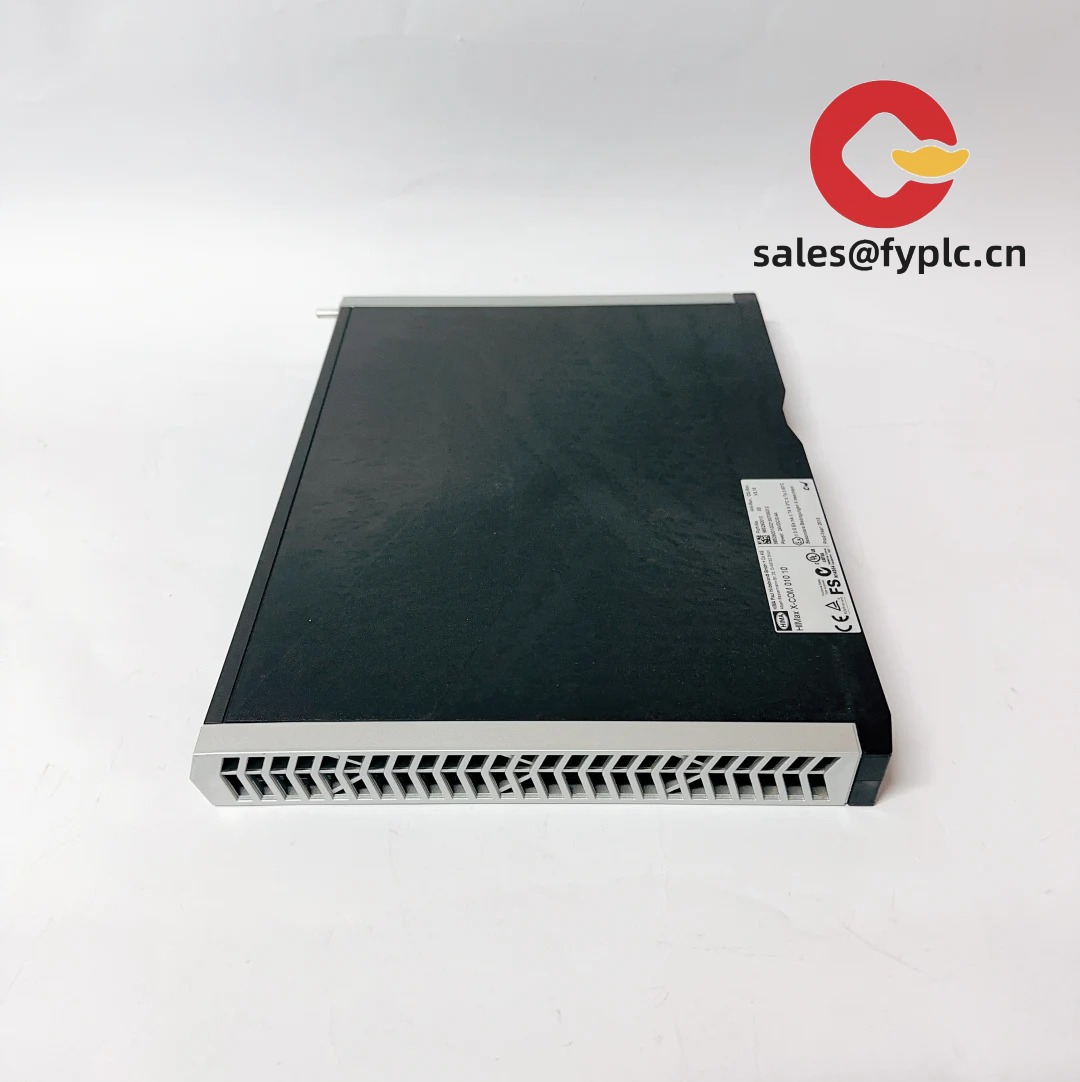

Weidmüller X-COM01010-985260010 – Pluggable X-COM System Module for Fast Panel Wiring and Maintenance

The Weidmüller X-COM system is built for control cabinets where speed, clarity, and reliability matter. The X-COM01010-985260010 is a pluggable terminal solution that typically lets you pre-assemble harnesses outside the cabinet, then plug them in during final build or service. From my experience, this cuts wiring time, reduces errors, and makes swap-outs a lot easier during downtime. You might notice that the modular design fits well in tightly packed panels, especially when you want clean separation between field wiring and the controller side.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Pluggable X-COM architecture – Speeds up installation and service by allowing pre-terminated wiring looms to be plugged in on-site.

- Clean separation of field and controller sides – In many cases, technicians can unplug the field side for testing without disturbing PLC-side wiring.

- Time-saving jumpers and markers – Compatible with Weidmüller bridging and marking accessories, making common potentials simple to distribute.

- Reliable spring or screw connection concepts – Typically supports secure clamping for vibration-prone machinery environments.

- Cabinet-friendly footprint – Compact profile that suits dense terminal rows on DIN rails.

- Serviceability – One thing I appreciate is how quickly a faulty circuit can be isolated and the module swapped, reducing downtime.

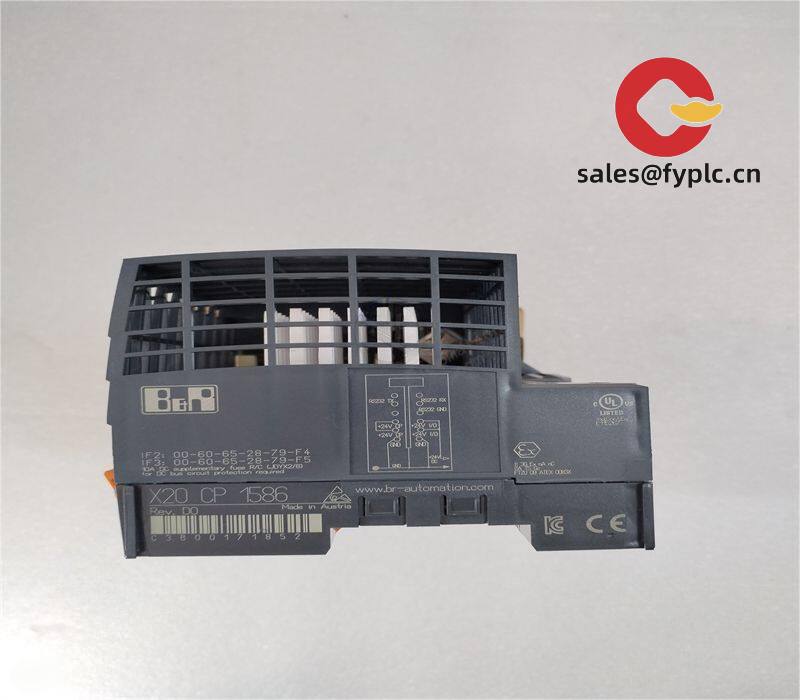

Technical Specifications

| Brand / Model | Weidmüller X-COM01010-985260010 (X-COM System) |

| HS Code | 853690 (Electrical apparatus for switching/protecting circuits; other) |

| Power Requirements | Passive component; no external power required |

| Operating Temperature | Typically -40°C to +105°C (depends on exact housing/material variant) |

| Signal Input/Output Types | Pluggable terminal contacts for control signals and low-to-medium power distribution; wire sizes commonly up to 2.5 mm² depending on version |

| Communication Interfaces | None (mechanical pluggable terminal system) |

| Installation Method | DIN-rail terminal base with plug-in connectors; panel/cabinet mounting in standard control enclosures |

| Materials & Flame Rating | Typically halogen-free PA, UL94 V-0 housing; tinned copper contacts (varies by variant) |

Application Fields

This model fits panel builders and OEMs who need modular wiring in:

- Machine building (packaging, food & beverage, textile lines) where quick changeovers are routine.

- Process skids and distributed I/O cabinets for chemical and water treatment plants.

- Material handling systems and conveyor controls with frequent maintenance windows.

- Energy and infrastructure panels that benefit from clear segregation between field and control wiring.

A maintenance supervisor told us their team “cuts panel rework time by roughly a third” after shifting to X-COM-style pluggables—seems to be especially true when testing loops or swapping assemblies in the field.

Advantages & Value for Procurement

- Reliability – Proven contact technology for stable connections under vibration and temperature cycling.

- Compatibility – Works within the Weidmüller X-COM ecosystem, including standard jumpers and markers.

- Cost Savings – Reduced panel wiring time and faster service interventions typically yield measurable labor savings.

- Traceability – Clear marking options make maintenance and audits more straightforward.

- Support – Available application support for selection, cross-references, and configuration advice.

Installation & Maintenance

- Cabinet requirements – Install on standard DIN rails within ventilated enclosures; avoid pooling heat sources; allow access for plugging/unplugging.

- Wiring – Use correctly sized ferrules; follow torque or push-in instructions per the chosen connection type; maintain conductor strip lengths as specified.

- Safety – De-energize circuits before plugging/unplugging; verify insulation distances if mixing low-voltage control and higher power lines.

- Routine checks – Periodically verify terminal tightness (for screw types), inspect for discoloration or debris, and clean with non-aggressive agents.

- Documentation – Keep terminal designations and marker strips current; this pays off during fault-finding.

Supporting Components (Typical Pairings)

- Weidmüller X-COM plug connectors and terminal bases (matching pole counts and pitch).

- Weidmüller ZQV bridging jumpers for common potentials.

- Weidmüller DEK or WS marker systems for clear labeling.

- End stops and end plates for stable DIN-rail mounting in long terminal rows.

Quality & Certifications

- Typically CE compliant

- UL Recognized / cURus approvals common in the X-COM range

- RoHS compliant materials

- Manufacturer’s warranty: commonly 1 year (varies by region and variant)

If you’re consolidating part numbers or need help cross-referencing to your existing terminal ecosystem, let me know your pitch, pole count, and connection preference (spring vs. screw). It usually takes just a few minutes to pinpoint the exact X-COM variant that matches X-COM01010-985260010 in your design.

Reviews

There are no reviews yet.