Description

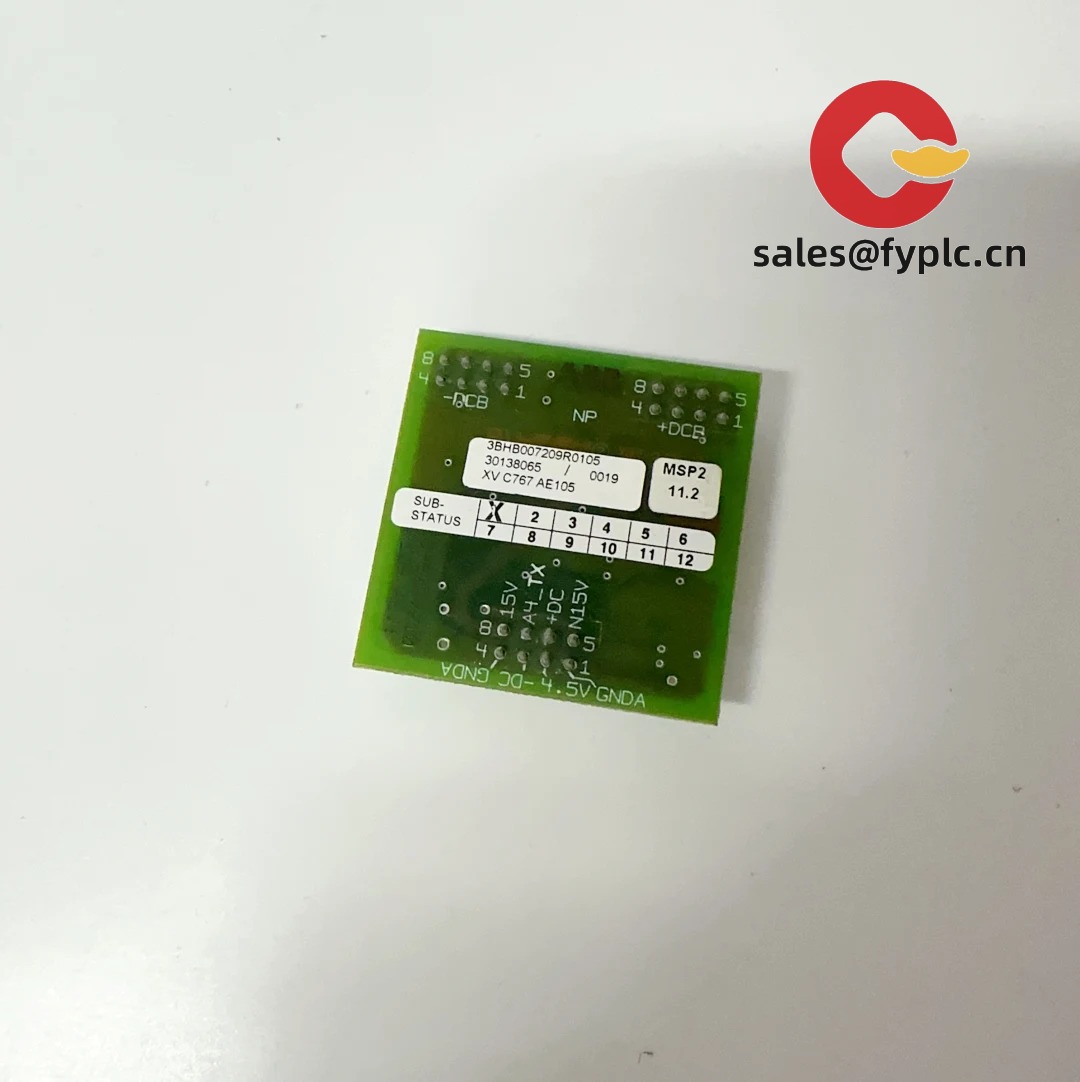

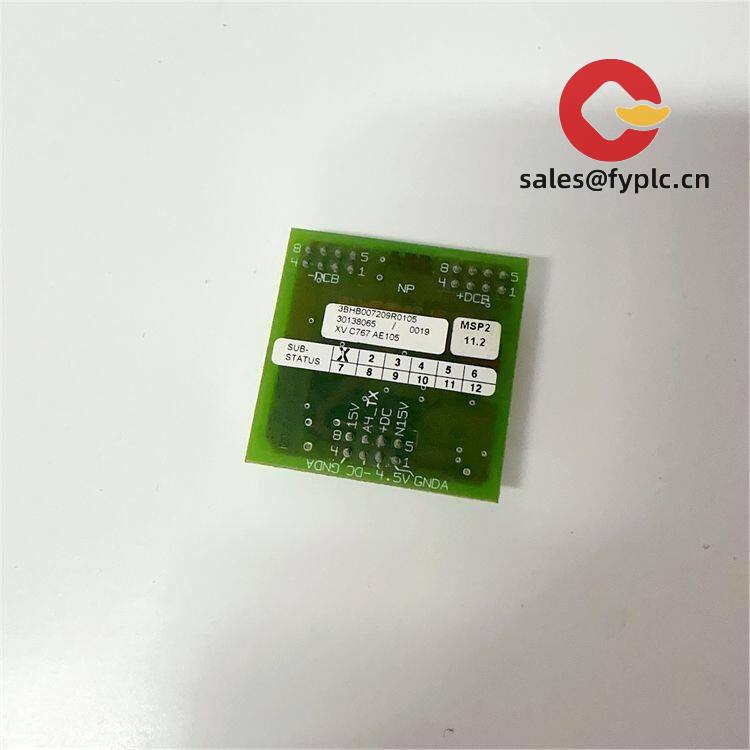

ABB XVC768102 (3BHB007211R102) Control Board – Reliable drive control core for industrial applications

The ABB XVC768102 – marked as 3BHB007211R102 – is a control board used in ABB drive systems where stable, deterministic control is key. From my experience, it’s typically deployed as a plug‑in board within the drive cabinet, handling real‑time control, interlocking, and communications with other modules. If you’re maintaining a process line where downtime costs pile up quickly, having a clean, tested replacement of this board on the shelf makes a big difference.

One thing I appreciate is how predictable it is once installed—most users report a straightforward swap if firmware and revision levels are matched to the host system. In many cases, you’ll see immediate restoration of normal operation after seating the board and confirming the status LEDs.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Drop‑in replacement – Designed as a plug‑in board for ABB drive cabinets, minimizing downtime during swap.

- Deterministic control – Stable processing for drive regulation and interlocks; helps maintain tight process control.

- Backplane powered – Typically powered from the host system (24 VDC nominal), reducing external wiring complexity.

- Status indicators – On‑board diagnostic LEDs (varies by revision) to quickly verify health and I/O state.

- Robust design – Industrial temperature ratings and component selection suitable for continuous operation inside cabinets.

- Traceable part identity – Clear labeling by part/revision (XVC768102 / 3BHB007211R102) for maintenance records.

Technical Specifications

| Brand / Model | ABB XVC768102 – 3BHB007211R102 |

| HS Code | 8538.90 – Parts for switchgear, control panels and similar apparatus |

| Power Requirements | Supplied via host backplane; typically 24 VDC, low power consumption (board‑level) |

| Operating Temperature | 0 to +55 °C (in‑cabinet; non‑condensing; typical for ABB control boards) |

| Signal I/O Types | Digital backplane signals; may interface to fiber‑optic links and interlocks depending on system configuration |

| Communication Interfaces | Proprietary ABB backplane bus; service access via the host drive/controller maintenance interface |

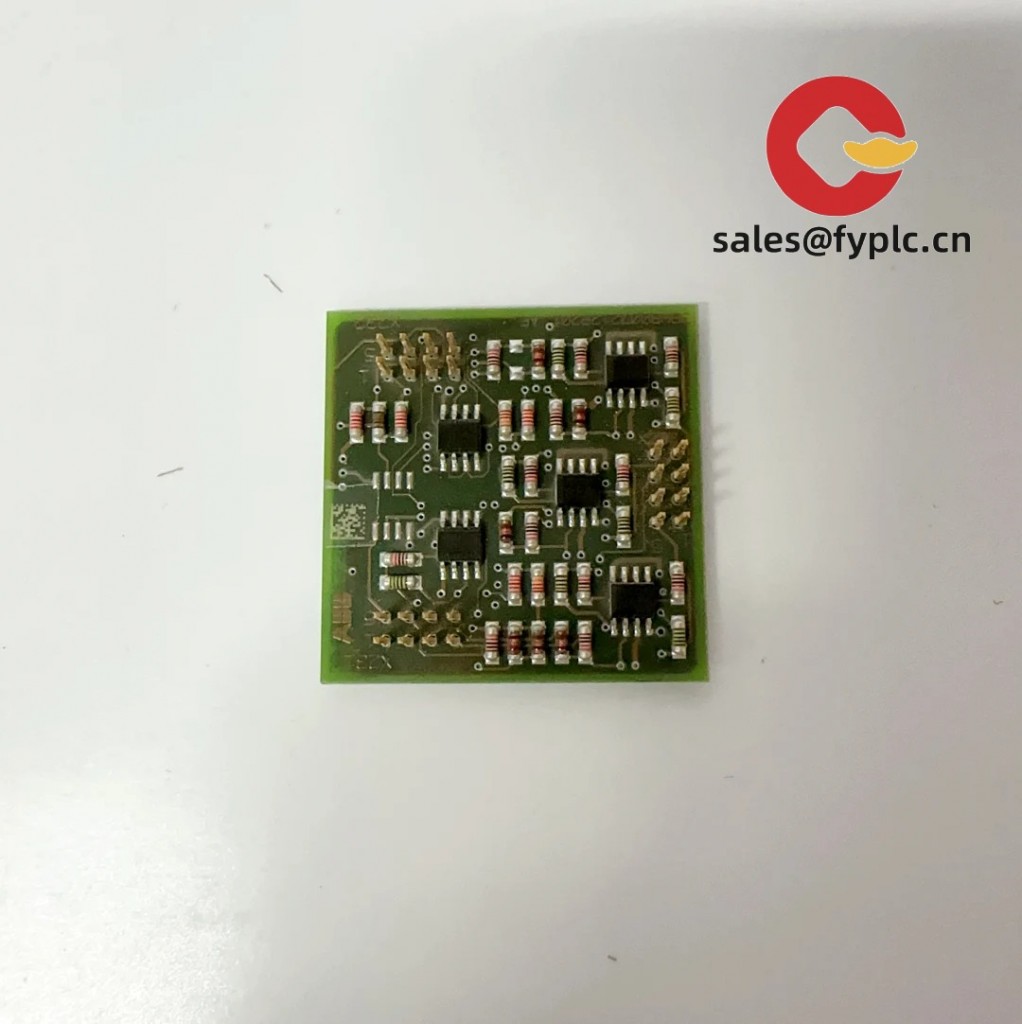

| Installation Method | Plug‑in board; mounts in the designated slot of the ABB drive/control rack; ESD‑safe handling required |

Application Fields

You’ll typically see the XVC768102 used in ABB drive systems across heavy industry where process stability matters:

- Metals and mining – mill drives, conveyors, hoists

- Cement and aggregates – kilns, crushers, clinker coolers

- Oil & gas and chemicals – compressors, process pumps, mixers

- Power and water – ID/FD/PA fans, feedwater pumps, high‑inertia loads

- Marine and infrastructure – propulsion auxiliaries, large HVAC drives

“Swapped the XVC board and the line came back in under an hour. Only had to match the firmware to our revision and it synced right up.” — Maintenance Supervisor, metals plant

Advantages & Value

- Reliability – Proven field performance in continuous‑duty environments; consistent behavior after replacement.

- Compatibility – Engineered for ABB drive racks; we can help verify revision/firmware fit before shipment.

- Cost control – Restores a down drive without the expense of a full system retrofit.

- Support – Pre‑ship functional testing and documentation on request to speed site commissioning.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry, ventilated cabinet; maintain ambient 0–55 °C and non‑condensing humidity.

- ESD and handling – Use grounded wrist straps and antistatic packaging; avoid touching component leads.

- Wiring/backplane – Power and signals are via the host backplane. Inspect connectors for wear; reseat firmly until latched.

- Firmware alignment – Match board firmware and hardware revision to the drive’s configuration; back up parameters before swap.

- Routine care – Quarterly dust removal with dry, oil‑free air; check status LEDs and diagnostic logs after power cycles.

- Spare strategy – Keeping a verified spare on site typically shortens recovery time to under one maintenance window.

Quality & Certifications

- CE compliance at system level; designed for use within ABB certified drive assemblies

- UL/CSA recognition typically applies at the complete drive/system level

- Manufacturing under ISO 9001 quality systems (ABB)

- RoHS conformity where applicable for spare parts

- Warranty: 365 days from delivery

Reviews

There are no reviews yet.