Description

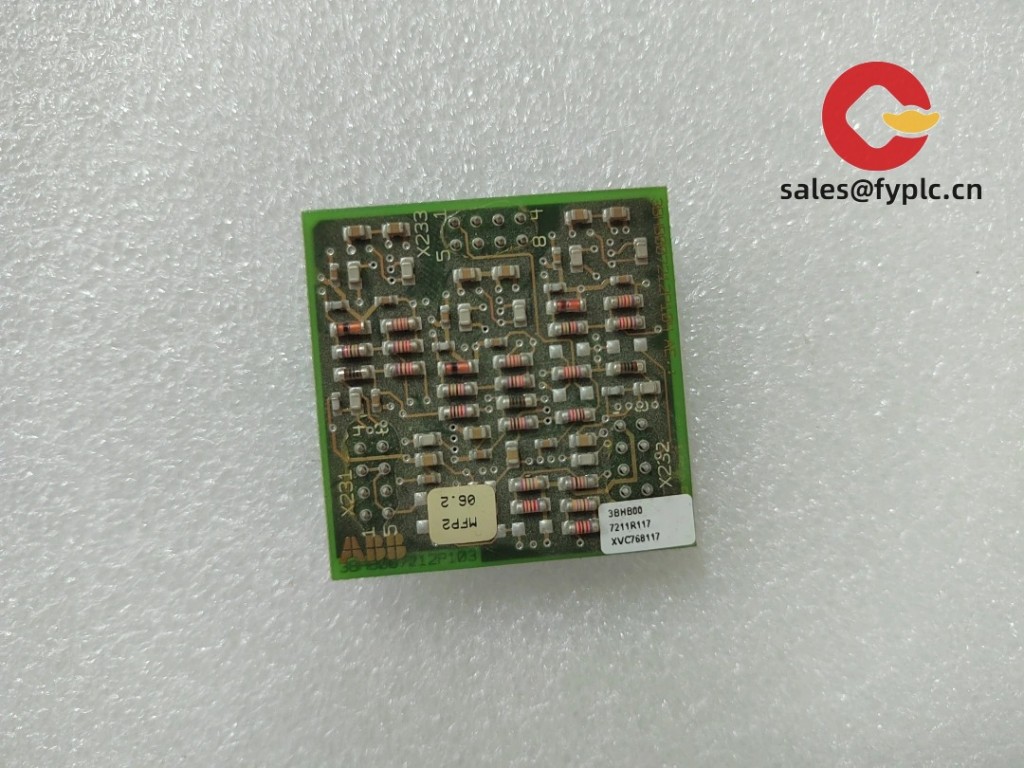

ABB XVC768115 (3BHB007211R115) – Control Board for ABB Industrial Drives and Converters

The ABB XVC768115, ordered under 3BHB007211R115, is a factory-grade control/drive interface board commonly used inside ABB low-voltage industrial drives and converter cabinets. It’s typically responsible for coordinating firing/control signals, supervising feedback, and interfacing between the power stage and the main control unit. From my experience, maintenance teams choose this board to restore a downed drive quickly without touching the entire power stack, shortening downtime and keeping commissioning simple.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Direct-fit ABB spare – Designed as a like-for-like replacement for the original XVC768115 board, keeping wiring and mounting familiar.

- Stable gate/control signaling – Typically handles fiber-optic or isolated signaling between control and power modules for reliable IGBT/thyristor drive operation.

- Diagnostics on board – You might notice status LEDs and test points that help technicians trace faults faster during commissioning.

- EMC-robust design – Built for electrically noisy environments found around high-power drives, which in many cases reduces nuisance trips.

- Service-friendly interchangeability – Swap-out usually requires minimal parameter changes since the logic ties back to the host drive firmware.

Technical Specifications

| Brand / Model | ABB XVC768115 – Order Code 3BHB007211R115 |

| HS Code | 8538.90 (Parts suitable for heading 8537 control panels/apparatus) |

| Power Requirements | Typically powered from the host drive’s internal low-voltage rail (commonly 24 VDC logic supply) |

| Dimensions & Weight | Board-level module; typical handling weight under 1 kg for panel installation |

| Operating Temperature | Typically 0–55 °C when installed inside a properly ventilated drive cabinet |

| Signal I/O Types | Isolated control lines and/or fiber‑optic links for power stage control; backplane connectors to host controller |

| Communication Interfaces | Proprietary ABB internal bus; service headers for maintenance as applicable to the drive family |

| Installation Method | Plug-in board within the drive/converter; secured with stand-offs and screws; ESD-safe handling required |

Application Fields

This module is typically used in ABB variable frequency drives and converter systems across:

- Pumps, fans, and compressors in water/wastewater and HVAC plants

- Material handling and cranes where steady torque control matters

- Pulp & paper, food & beverage, and cement lines running continuous processes

- Metals and mining conveyors where downtime costs escalate fast

One thing I appreciate is how straightforward the swap can be: a maintenance lead at a cement mill told us they had the drive back online in under two hours after replacing this board, with just a quick parameter check and a fiber reconnection.

Advantages & Value

- Reliability: Genuine ABB-design board helps stabilize drive control loops and fault handling in demanding plants.

- Compatibility: Built for ABB drive ecosystems; in many cases, no mechanical adaptation is needed.

- Cost & uptime: Replacing the board instead of a full drive section typically cuts costs and slashes downtime.

- Technical support: We can assist with compatibility checks using your drive type code/serial to avoid guesswork.

Installation & Maintenance

- Environment: Install inside an IP-rated cabinet with adequate ventilation. Keep clear of high-voltage cabling where possible to limit EMI.

- Handling: Use ESD protection. Isolate mains, wait for DC bus to discharge, then proceed. Verify fiber connectors are clean and properly latched if applicable.

- Wiring: Follow the host drive drawings. Maintain bend radii on fibers and secure harnesses to avoid vibration wear.

- Routine care: Periodic dust cleaning with dry air, check terminal torque, and review event logs. Firmware matching should be confirmed during commissioning when relevant.

- Commissioning tip: After replacement, run a low-load test and verify interlocks, analog scaling, and direction logic.

Quality & Certifications

- Manufactured under ISO 9001 quality systems

- CE-compliant assemblies for use within compliant ABB drive systems

- RoHS-compliant board materials, as typically provided for ABB service parts

- 365-day warranty coverage

If you share your drive type code, frame size, and serial, we’ll double-check that XVC768115 (3BHB007211R115) is the correct revision for your cabinet. That little step usually prevents repeat interventions.

Reviews

There are no reviews yet.