Description

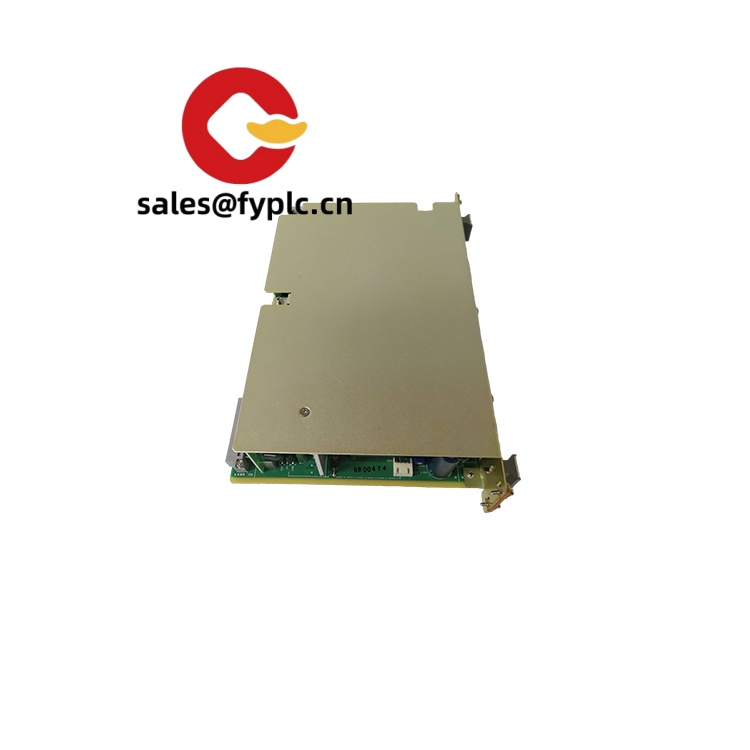

YASKAWA CPS-150F – Power Supply Module for MOTOMAN/YASNAC Robot Controllers

The YASKAWA CPS-150F is a dedicated power supply module used inside YASKAWA robot controllers to provide regulated low-voltage DC rails for the control logic, I/O, and internal circuits. From my experience, it’s the part that quietly keeps the controller stable—when this module is healthy, startups are consistent and nuisance faults tend to disappear. You might notice that maintenance teams often keep one on the shelf because downtime from a tired PSU can be costly.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week for in-stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Controller-grade power stability – Provides the regulated DC rails the controller logic and I/O depend on, helping prevent random resets and boot errors.

- Drop-in module for YASKAWA controllers – Designed to mount inside the robot controller chassis; connectors and mounting points are typically keyed and straightforward.

- Integrated protection – Typically includes internal fusing/overcurrent and thermal safeguards to protect downstream circuits.

- Service-friendly indicators – Status LEDs and clear harnessing make troubleshooting faster in most cases.

- Stable low-voltage rails – Supplies logic-level voltages (commonly 5 V/24 V) for the CPU board, I/O, and peripheral control inside the cabinet.

Technical Specifications

| Brand / Model | YASKAWA CPS-150F |

| HS Code | 8504.40 (Static converters / power supplies) |

| Power Requirements | Typically sourced from controller mains; AC 200–230 V, 50/60 Hz (controller-dependent) |

| Operating Temperature | Approx. 0–45°C (non-condensing, within controller cabinet ambient) |

| Signal Input/Output Types | Regulated DC output rails for logic and I/O (e.g., 5 V, 24 V), status indicator signals |

| Communication Interfaces | None (power conversion module) |

| Installation Method | Internal mounting in YASKAWA robot controller chassis; secured with screws/guide rails and keyed harness connectors |

| Dimensions & Weight | Controller-module form factor; varies by controller series and revision |

Notes: Exact electrical ratings and connector assignments can vary by controller family and CPS-150F revision. For critical integration, match against your controller part list or send us photos of the nameplate and backplane connectors for confirmation.

Application Fields

- YASKAWA MOTOMAN robot controllers in welding, handling, palletizing, and machine tending cells

- General factory automation cabinets where controller-grade DC rails are required

- Spare-part programs and preventive maintenance for legacy and current YASKAWA controller fleets

Advantages & Value

- Reliability first – Stable DC rails reduce random faults and controller reboots, which in many cases saves more downtime than any other single spare.

- Compatibility – Designed for YASKAWA controller architecture; no rewiring or hacked brackets.

- Cost control – A targeted replacement can delay a far more expensive controller swap.

- Technical support – We can help verify revision compatibility from your controller ID or photos of the existing CPS module.

Installation & Maintenance

One thing I appreciate is how straightforward replacement tends to be: power down, lock-out/tag-out, remove the controller cover, then swap the module using the keyed connectors. Still, there are a few best practices worth noting.

- Environment: Install inside an industrial control cabinet that meets IEC/UL enclosure standards; allow adequate ventilation around heat-producing components.

- Power & grounding: Verify earth bonding to the controller chassis; route AC mains and DC harnesses separately to minimize noise.

- Wiring: Use the original harness set; do not alter connectors. Confirm pin orientation before seating.

- Safety: De-energize, wait for DC bus discharge, and check with a meter before touching. ESD protection is recommended when handling boards.

- Routine checks: Inspect connectors for discoloration or looseness, clean dust with dry air, and confirm LED status during commissioning.

- Spare strategy: In most cases, keeping one CPS module per line minimizes recovery time during unplanned stops.

Quality & Certifications

- Typically produced to CE requirements for machinery EMC/safety when installed in compliant YASKAWA controllers

- UL recognition for controller assemblies (region-dependent)

- RoHS-compliant components where applicable

- Manufacturer’s policy commonly supports standard warranty; we provide a 365-day warranty on this item

Practical Notes from the Field

A maintenance lead told us they were chasing intermittent CPU faults on a welding cell—after swapping in a CPS-150F, the controller booted cleanly and the issue didn’t return. It seems mundane, but power stability solves a surprising number of “ghost” errors on aging systems.

Reviews

There are no reviews yet.