Description

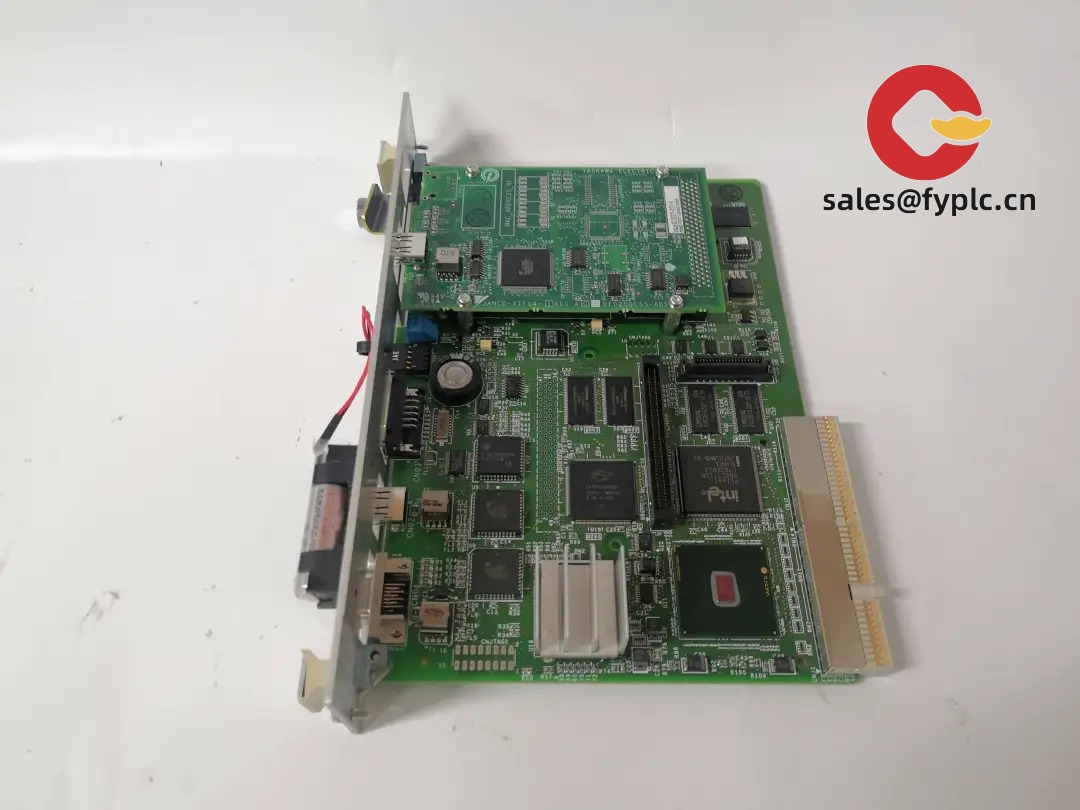

Yaskawa JANCD-XCP01C-1 CPU Board – Core control board for YASNAC XRC robot controllers

This listing covers the Yaskawa JANCD-XCP01C-1 CPU board (you might also see it written as “YASKAWA-JANCD-XCP0101C-1” in some lists; the functional item is the XCP01C-1 CPU board). It’s the central processing board used in YASNAC XRC controllers, typically running motion control, trajectory planning, and system coordination for Motoman UP/HP series robots and similar generations. From my experience, it’s the board maintenance teams keep on hand to reduce downtime—swap in, restore the backup, and you’re back producing fast.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: Typically 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment, full payment before delivery

- Shipping options: FedEx, UPS, DHL (express)

- Pre-shipment checks: Basic functional test and visual inspection, anti-static packaging

Key Features

- Direct replacement for XRC CPU – Designed as the main processor board for YASNAC XRC controllers; minimizes integration risk during maintenance.

- Stable real-time motion control – In many cases, offers reliable task execution and precise path control when matched with correct firmware and robot data.

- Backplane integration – Communicates over the XRC internal bus; no rework to the panel layout when replacing like-for-like.

- Diagnostic indicators – Status LEDs help technicians verify boot, run, and fault conditions at a glance.

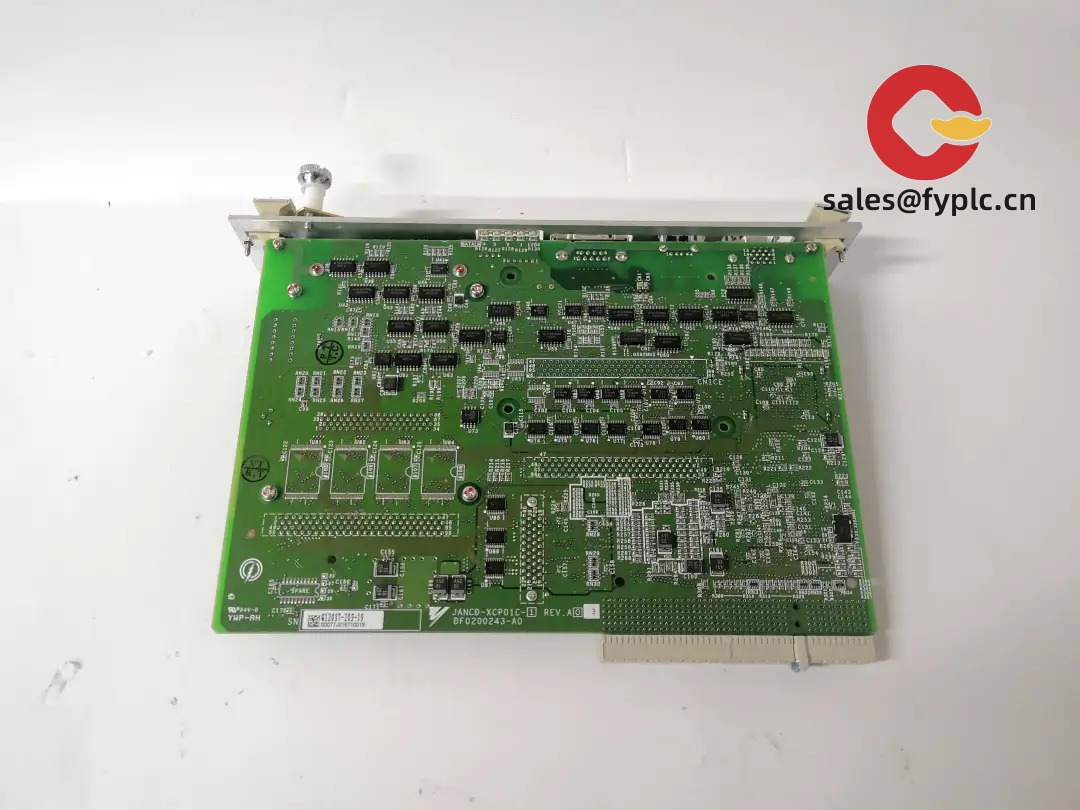

- Revision C-1 – The “C-1” revision is commonly used in later XRC builds and service replacements; check your controller version for match.

- Field-proven compatibility – Typically found in UP/HP series XRC systems for handling, arc welding, and spot welding applications.

Technical Specifications

| Brand / Model | Yaskawa JANCD-XCP01C-1 (often listed as YASKAWA-JANCD-XCP0101C-1) |

| HS Code | 853890 (Parts suitable for use with apparatus of 8537) |

| Power Requirements | Supplied via XRC controller backplane; typically 5 VDC logic rail |

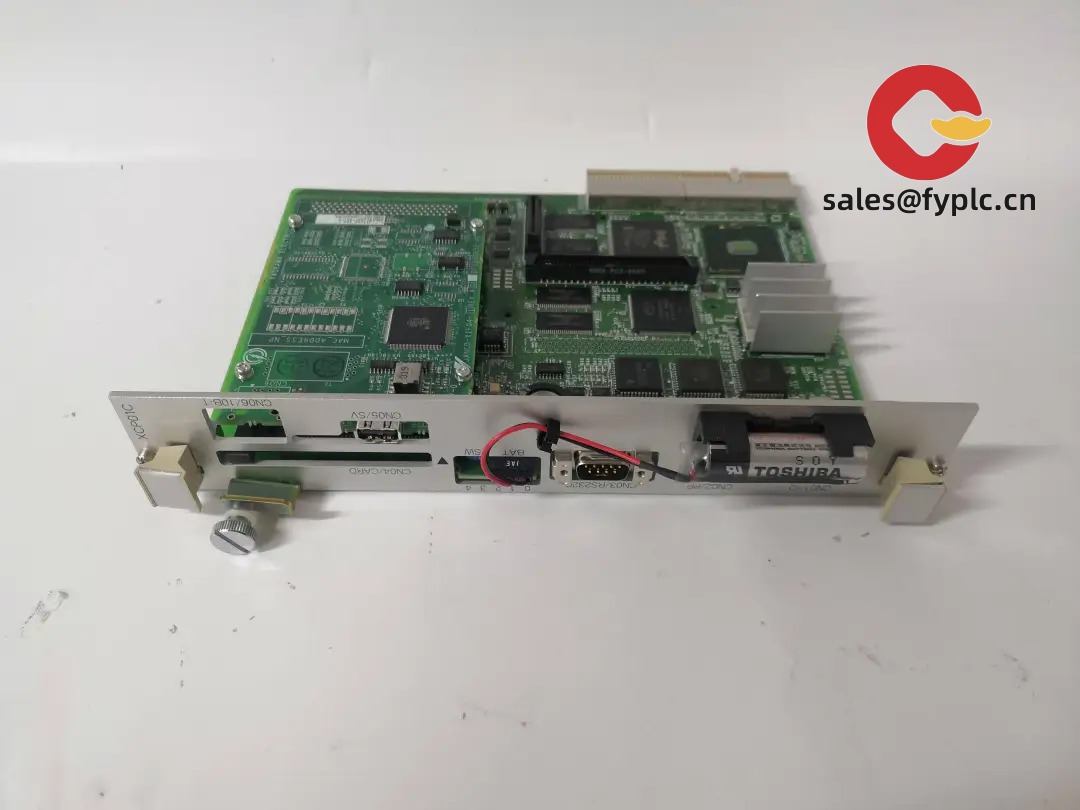

| Dimensions & Weight | Standard JANCD plug-in board format (approx. board length ~330 mm); weight typically around 0.5 kg |

| Operating Temperature | 0 to 45 °C, 5–85% RH non-condensing (controller cabinet environment) |

| Signal I/O Types | Internal system and motion control buses; no direct field I/O on the board face |

| Communication Interfaces | Backplane communication to XRC subsystems; service/maintenance access via controller ports (serial supported by system) |

| Installation Method | Slide-in backplane card for YASNAC XRC rack; secured with captive screws; ESD-safe handling required |

| Controller Compatibility | YASNAC XRC robot controllers (typical across Motoman UP/HP series; confirm firmware match) |

Application Fields

You’ll mostly see the JANCD-XCP01C-1 in production lines where XRC-based robots are still running strong. It seems to be a common spare in:

- Automotive welding cells (spot and arc)

- Material handling and palletizing stations

- Machine tending and press loading

- General assembly lines using legacy XRC platforms

“We swapped the XCP01C-1, restored our CMOS backup, and were back in production before shift change.” — Maintenance Supervisor, Tier-1 Auto Supplier

Advantages & Value

- Lower downtime risk – Drop-in replacement when matched to your controller revision; reduces troubleshooting time.

- Compatibility-first – Works with existing XRC racks, wiring, and teach pendant data; no re-engineering.

- Cost control – In many cases, extending the life of an XRC cell is far more cost-effective than a full controller retrofit.

- Supportive process – We help verify part numbers, revisions, and backups before shipment to avoid surprises.

Installation & Maintenance

- Cabinet environment – Install inside the XRC controller rack with adequate ventilation; keep dust to a minimum.

- ESD safety – Use a grounded wrist strap; power down and wait for discharge before handling the board.

- Seating & fastening – Insert evenly into the backplane guide; tighten captive screws to manufacturer torque.

- Backups – Before swapping, back up robot CMOS/parameters and jobs; after install, verify firmware and checksum.

- Routine care – Periodically blow out dust with dry air; check controller fans and ambient temperature. Firmware updates should match your robot system version—don’t mix revisions without guidance.

- Battery/CMOS – Some XRC systems rely on backup batteries for memory; ensure battery health to prevent data loss.

Quality & Certifications

- Certifications (system level): XRC controllers are typically CE-compliant as complete units; board-level markings may vary by revision.

- RoHS/UL: Compliance depends on production lot and market; we can confirm by serial before shipment.

- Warranty: 12 months (365 days) hardware warranty; replacement or repair per test results.

Supporting Components (commonly paired)

- Yaskawa JANCD-XIF series I/O interface boards – field I/O expansion

- Yaskawa JANCD-YIF/CP type communication boards – peripheral and network interfacing

- Teach pendant for XRC – operator programming and diagnostics

- Backplane and power modules – ensure stable 5 VDC logic rail and proper slot allocation

One thing I appreciate is how predictable these boards are when the firmware and controller version match—most issues I’ve seen come from revision mismatch or incomplete backups. If you can share your controller nameplate and current board labels, we’ll validate compatibility before you place the order.

Reviews

There are no reviews yet.