Description

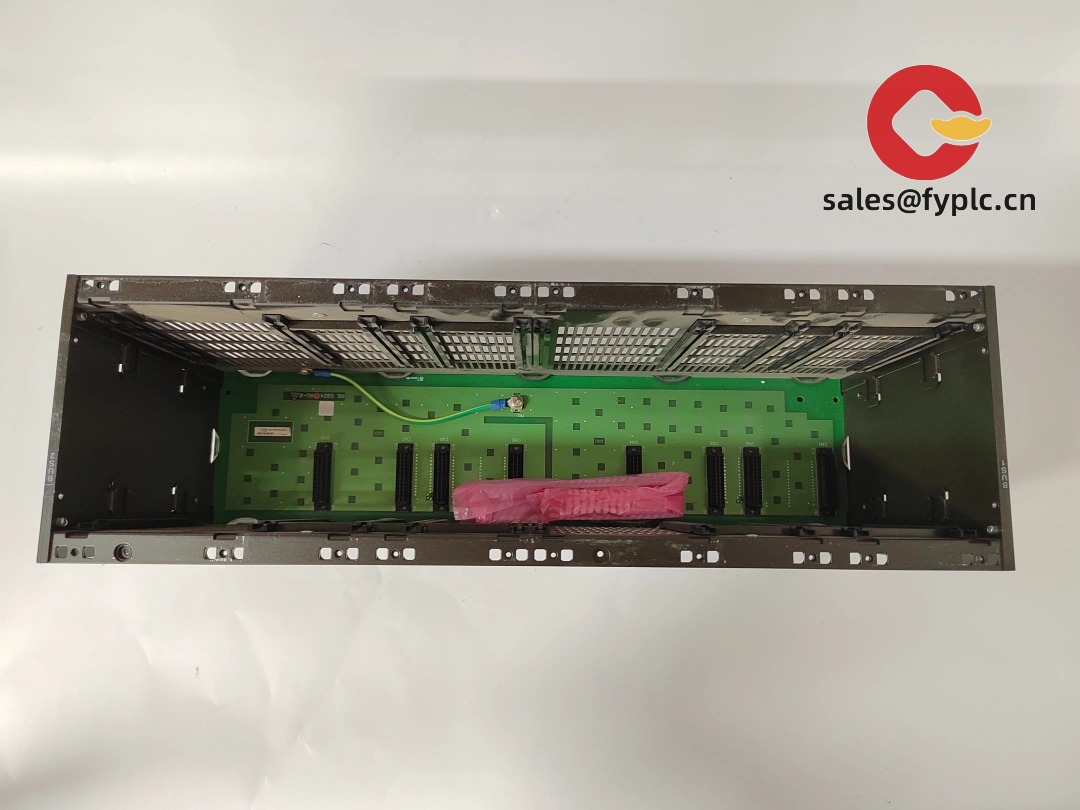

Yokogawa YNT511D – Network Interface Module for CENTUM control systems

The Yokogawa YNT511D is a communication/network interface module typically used within CENTUM series control systems to link controller nodes and engineering/operator stations over Vnet/Vnet-IP networks. From my experience, plants use it to secure redundant, deterministic communications between the FCS and higher-level workstations without touching the core control logic. You might notice that it’s designed as a rack-mounted module powered from the system backplane, which makes upgrades and replacements straightforward during a planned shutdown.

Our Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Each unit is powered-on tested and packed with ESD and shock protection before dispatch

Key Features

- Redundant network links – Supports dual-channel network connectivity for high availability on Vnet/Vnet-IP segments in many cases.

- Deterministic control communications – Designed for real-time distributed control traffic between FCS and HIS/ENG nodes.

- Backplane powered – Draws low-voltage DC from the system rack, simplifying wiring and cabinet layout.

- Status diagnostics – Front-panel indicators typically provide link, activity, and module health status for quick checks.

- Rack-mounted form factor – Fits Yokogawa system cabinets, easing replacement and sparing strategies.

- Compatibilities – Deployed with CENTUM series controllers and workstations; seems to be commonly paired with redundant switches and engineering stations.

Technical Specifications

| Brand / Model | Yokogawa YNT511D |

| HS Code (reference) | 8538.90 (Parts for industrial control panels) |

| Power Requirements | Backplane supplied DC (typically 5 VDC); low power, often < 10 W |

| Dimensions & Weight | Approx. 130(H) × 25(W) × 170(D) mm; ~0.3–0.5 kg (varies by revision) |

| Operating Temperature | 0 to 50 °C (typical control room conditions) |

| Signal I/O Types | Industrial Ethernet for control network; redundant ports commonly used on Vnet/Vnet-IP |

| Communication Interfaces | Typically dual 100BASE-TX (RJ45) for redundant links; backplane interface to controller |

| Installation Method | Rack-mounted module, front-insertion into Yokogawa system base, latch secured |

Application Fields

Plants typically deploy the YNT511D anywhere they need reliable controller-to-workstation communications:

- Oil & Gas: DCS networking across process units with redundant rings

- Chemical & Petrochemical: Linking FCS and operator stations in hazardous-area compliant cabinets

- Power Generation: Control room networks for boiler/turbine controls

- Pharmaceutical & Food: Validated control networks with stable response and audit trails

- Metals & Mining: Harsh-environment cabinets with managed switch redundancy

“We replaced a legacy comms card with YNT511D during a minor outage—redundant links came up cleanly and our HIS nodes synced right away.” — Maintenance Supervisor, polymer plant

Advantages & Value

- Reliability – Redundancy and robust diagnostics reduce single-point failures on the control network.

- Compatibility – Suited to CENTUM-based architectures; integrates with standard managed industrial switches approved for Vnet/Vnet-IP.

- Lifecycle savings – Drop-in rack design means short swap times and less downtime during maintenance windows.

- Spares strategy – Common form factor helps consolidate spares across multiple units and areas.

- Support – We can assist with module health checks, firmware matching, and network redundancy tests before shipment.

Installation & Maintenance

- Cabinet standards – Install in a clean, ventilated DCS cabinet; allow front access for insertion/removal and rear clearance for cabling.

- Ventilation – Maintain ambient 0–50 °C and avoid hot spots near power supplies; provide forced-air if cabinet is densely populated.

- Wiring – Use shielded, industrial-grade Cat5e/Cat6 for redundant ports; route separately from high-voltage lines; earth shielding at one end as per plant standards.

- Redundancy – Connect both network ports to independent switch paths; verify switchover behavior before handover.

- ESD & handling – Use ESD protection; power down or follow hot-standby procedures defined by your DCS when replacing modules.

- Routine care – Periodically check connectors, clean dust filters, log link errors, and align firmware with the host system where applicable.

Quality & Certifications

- Manufacturer quality system: ISO 9001

- Conformity: CE, RoHS (typical for Yokogawa control modules)

- Safety listing: UL (region-dependent; check specific revision)

- Warranty: 365 days from shipment

Related/Supporting Components

To build a dependable DCS network around the YNT511D, users typically pair it with:

- CENTUM controller (FCS) base rack and power supply units

- Operator/engineering workstations connected over Vnet/Vnet-IP

- Industrial managed Ethernet switches configured for redundant paths

- Shielded patch leads and cabinet-rated accessories for proper grounding

Note: Specifications may vary by system revision and site standard. If you share your target firmware level or existing rack part numbers, we can match a compatible YNT511D build and run a bench test with redundant links before shipping.

Reviews

There are no reviews yet.