Description

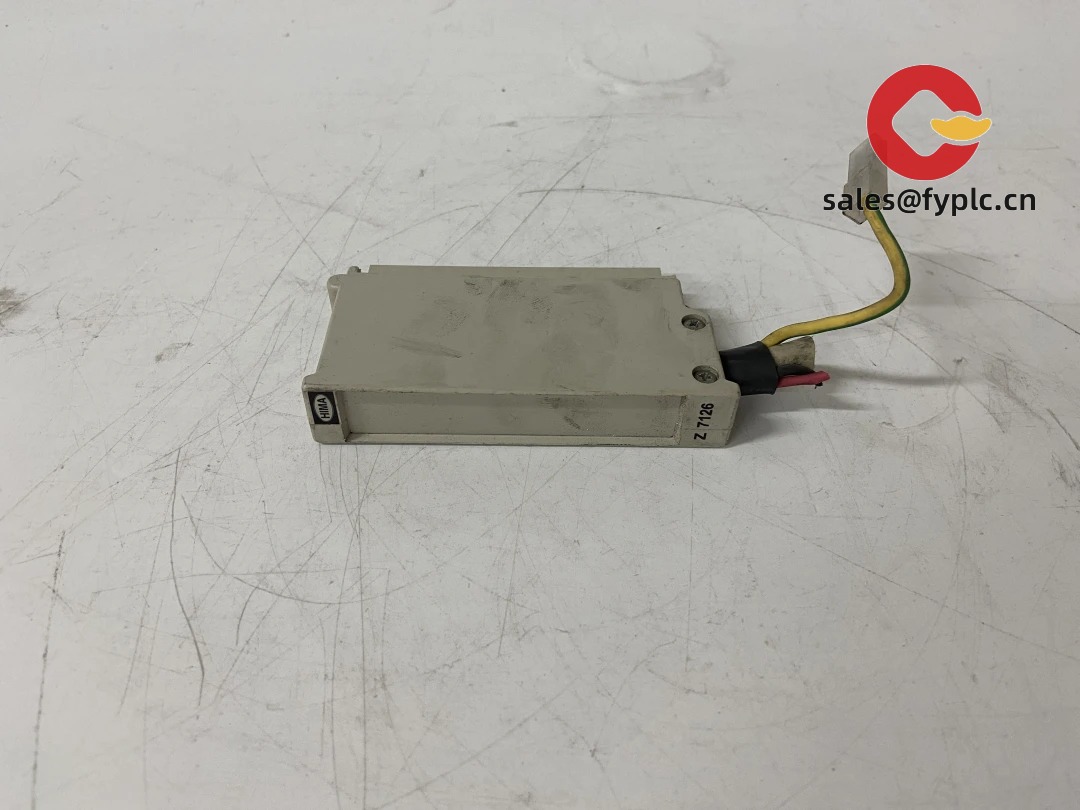

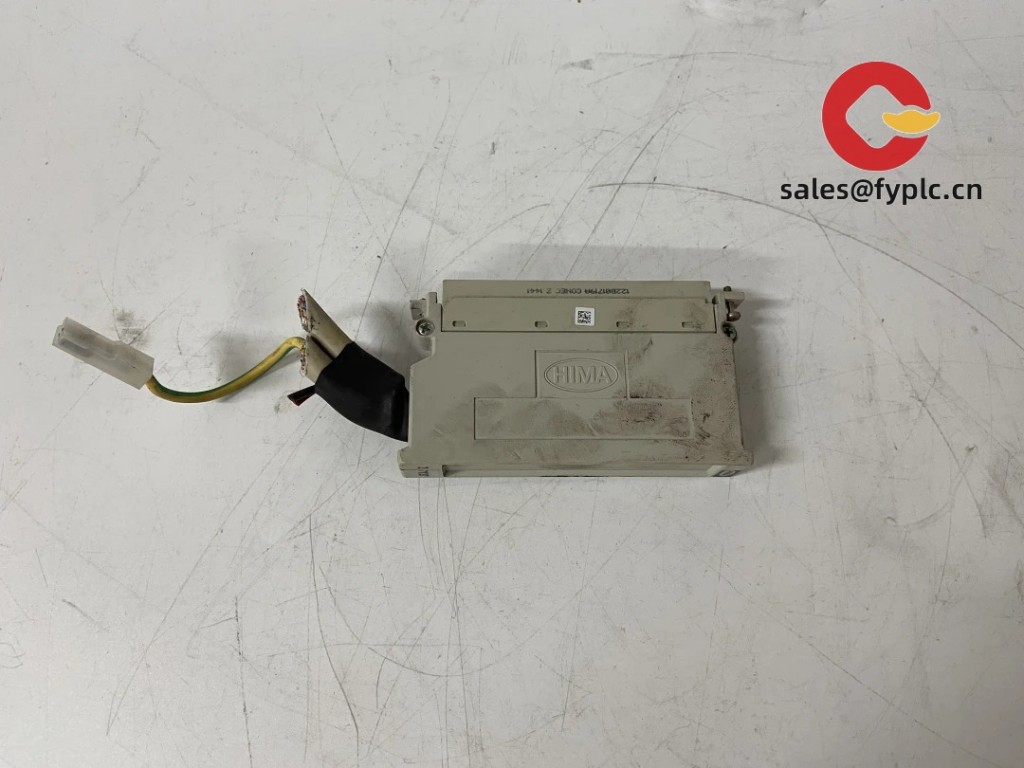

OMRON Z-7126 Basic Micro Switch – Reliable Limit Detection for Industrial Machinery

The OMRON Z-7126 belongs to the Z-7 series of compact snap-action micro switches. From my experience, it’s the kind of straightforward, trustworthy component you use for precise on/off position sensing when space is tight—conveyors, packaging stations, light safety interlocks, jig fixtures, even simple home-back positions on small machines. One thing I appreciate is the consistent actuation feel; it typically delivers clean, repeatable switching without needing any external power.

Our Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Compact snap-action mechanism – Ensures crisp, repeatable switching for consistent limit detection.

- SPDT contact (1NO + 1NC) – Simple wiring to PLC digital inputs or relay logic, typically without additional conditioning.

- Industrial current rating – Commonly 7 A at 250 VAC; suitable for control circuits and light-duty power switching.

- Mechanical durability – In many cases tested to millions of operations under light loads, reducing unplanned downtime.

- Versatile mounting – Fits into tight fixtures; straightforward panel or bracket mounting with small screws.

- Passive device – No external power required, which keeps panels simpler and reduces failure points.

Technical Specifications

| Brand / Model | OMRON Z-7126 (Z-7 series, basic micro switch) |

| HS Code | 853650 (Switches, for a voltage not exceeding 1,000 V) |

| Power Requirements | None (mechanical). Rated switching up to 250 VAC, typically 7 A |

| Dimensions & Weight | Approx. 28.8 × 10.3 × 15.9 mm (body), ~12 g |

| Operating Temperature | -25 to +80°C (non-freezing, non-condensing) |

| Signal Input/Output Types | SPDT snap-action contacts: COM, NO, NC |

| Communication Interfaces | None (wired contacts to PLC/relay) |

| Installation Method | Panel or bracket mount with small screws (e.g., M2.6). Termination via quick-connect or solder terminals depending on variant |

Application Fields

You might notice the Z-7126 shows up most in compact mechanisms where precise end-of-travel confirmation matters:

- Packaging lines – Gate position, carton presence, and cam indexing feedback.

- Conveyors & material handling – Limit positions, diverter confirmation, and stop points.

- Electronics assembly & small jigs – Home sensors, fixture clamping confirmation.

- Textile, printing, and light machinery – Travel limits and interlock status in tight spaces.

- Door/cover interlocks – Non-safety indication for access panels and guards.

Advantages & Value

- Reliable snap action – Stable switching point helps reduce false trips in vibration-prone setups.

- Easy drop-in replacement – Common footprint and contact scheme keep changeouts under 10 minutes in many cases.

- Broad compatibility – Works seamlessly with standard PLC digital inputs and relay coils.

- Cost control – Durable mechanics and simple wiring typically lower lifecycle costs versus sensors that need power and conditioning.

- Support & availability – Short lead times and a 365-day warranty make procurement straightforward.

Installation & Maintenance

- Cabinet/environment – Mount in a clean, dry location or provide shielding; keep within the rated temperature range.

- Ventilation & spacing – Avoid heat sources; allow enough travel clearance to prevent over-travel on the actuator.

- Wiring – Use crimped quick-connects or soldered joints; route away from high-voltage lines to minimize noise coupling to PLC inputs.

- Safety – De-energize circuits before wiring. Verify contact logic (NO/NC) during commissioning.

- Routine checks – Inspect actuator wear, confirm repeatability, and retighten mounting screws every service interval.

- Cleaning – Wipe dust and oil residues; avoid solvent ingress that could affect plastics and seals.

Quality & Certifications

- Certifications: CE, UL/cUL, RoHS (typical for OMRON Z-series micro switches)

- Manufacturer quality: Produced under ISO-managed processes

- Warranty: 365 days from shipment

Helpful Accessories & Options

- Actuator styles: Hinge lever, roller lever, and plunger variants to suit different cam profiles.

- Mounting brackets: L-brackets and adjustable standoff brackets for quick fixture alignment.

- Terminal boots: Dust/oil protective boots for harsher environments.

- Pre-crimped leads: 2.8 mm quick-connect leads to speed up panel wiring.

A maintenance lead at a packaging plant told me the Z-7 footprint was “the fastest swap we do on the line,” mainly because the wiring and bracket holes match what they already had. That seems to be the common experience when upgrading older limit contacts without redesigning the fixture.

Reviews

There are no reviews yet.