Description

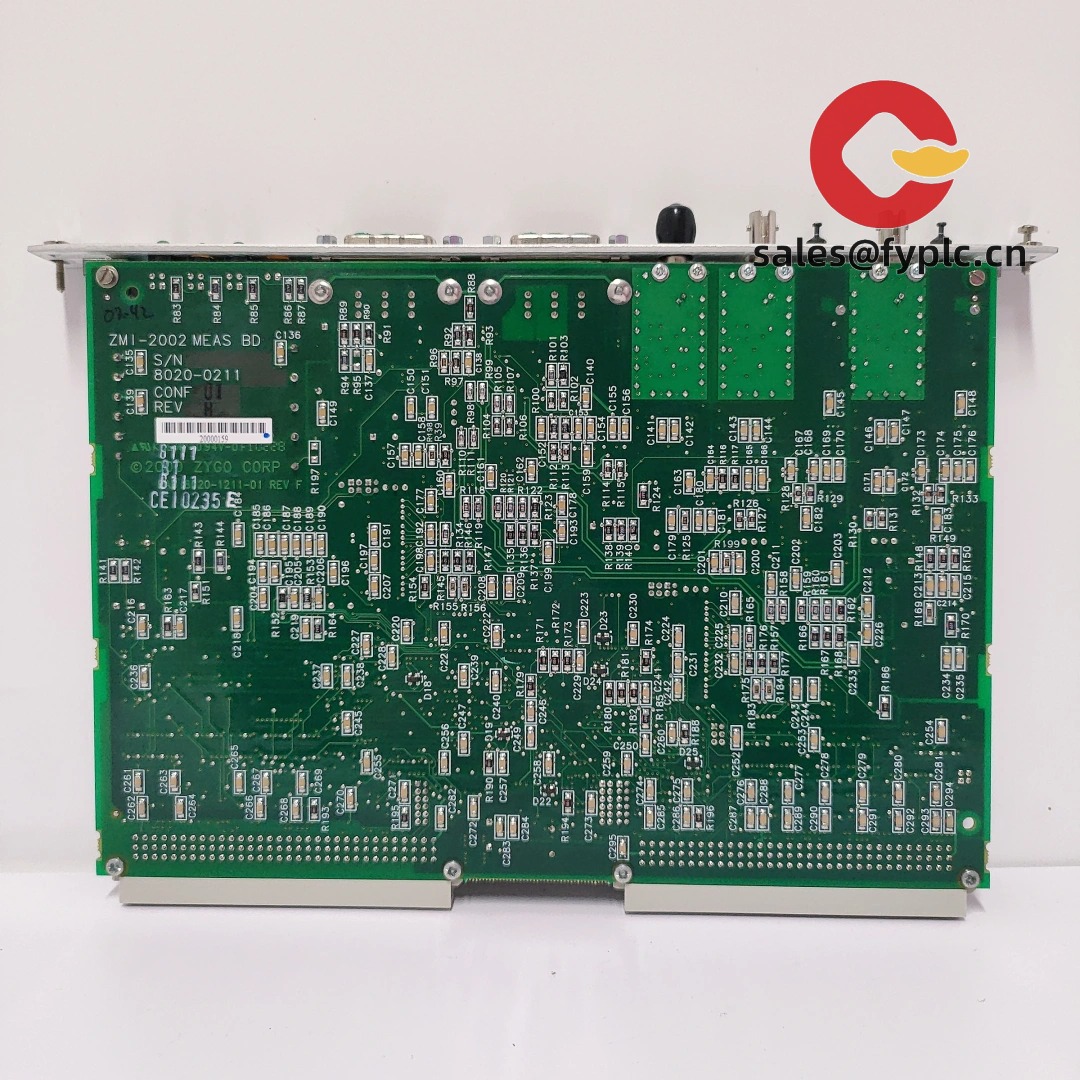

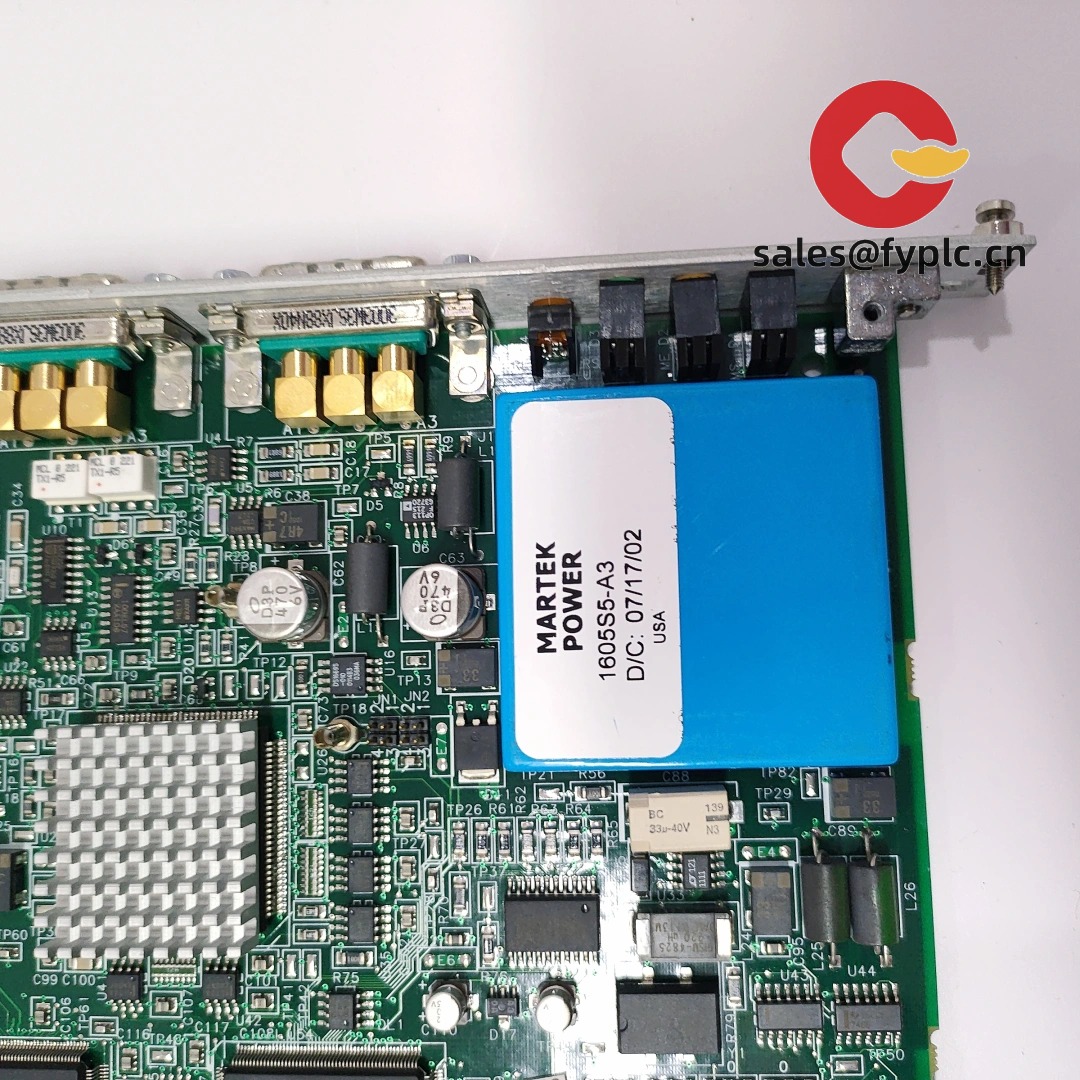

ZYGO ZMI-2002 (P/N 8020-0211) – Dual‑axis heterodyne interferometer electronics for precision stage feedback

The ZYGO ZMI‑2002 (part number 8020‑0211) is a plug‑in measurement module from the ZMI 2000 series, designed to deliver stable, sub‑nanometer position feedback for high‑end motion platforms. From my experience, it’s used widely in semiconductor stages, precision gantries, and metrology tools where you want reliable heterodyne interferometer measurements without fighting drift or noisy edges. One thing I appreciate is how cleanly it drops into a ZMI 2000 chassis and speaks in the “language” motion controllers expect—typically RS‑422 encoder emulation alongside ZYGO’s own high‑integrity serial link.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week when in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

- Units are tested prior to shipment; ESD-safe packing and shock protection

Key Features

- Dual‑axis heterodyne measurement – Supports two interferometer measurement channels for multi‑axis stages or stage + reference mirror setups.

- Sub‑nanometer interpolation – Delivers ultra‑fine position feedback that, in many cases, removes the need for secondary encoders on critical axes.

- RS‑422 encoder emulation – Differential quadrature output for straightforward integration with industrial motion controllers.

- Fiber‑based ZMI link – ZYGO’s robust serial link helps maintain signal integrity over distance and through noisy environments.

- Backplane integration – Installs into the ZMI 2000 chassis; no separate power brick or field wiring headaches.

- Designed for cleanroom use – Typically stable in temperature‑controlled environments, ideal for lithography, inspection, and high‑precision assembly tools.

Technical Specifications

| Brand / Model | ZYGO ZMI‑2002 (P/N 8020‑0211) |

| HS Code | 9031.80 (Measuring or checking instruments, not specified elsewhere) |

| Power Requirements | Powered via ZMI 2000 chassis backplane; the chassis typically accepts 100–240 VAC, 50/60 Hz |

| Dimensions & Weight | Single‑slot plug‑in module for ZMI 2000 series chassis; front‑panel secured with captive screws |

| Operating Temperature | Typically 10–40 °C, non‑condensing; best performance in temperature‑controlled environments |

| Signal Input/Output Types | Two heterodyne interferometer channels; RS‑422 quadrature/marker outputs; ZMI fiber serial link; backplane I/O |

| Communication Interfaces | Proprietary ZMI fiber link to chassis/system controller; differential RS‑422 encoder emulation to motion control |

| Installation Method | Plug‑in to ZMI 2000 chassis slot; no field calibration typically required after replacement |

Application Fields

You’ll most often see the ZMI‑2002 paired with precision stages where low noise and repeatability are non‑negotiable. Typical uses include:

- Semiconductor lithography and wafer inspection stages

- Flat‑panel display and photonics alignment systems

- High‑accuracy XY/XYZ gantries in metrology tools

- Precision bonding, laser processing, and micro‑assembly equipment

- Calibration benches where traceable displacement data is required

“We swapped in the ZMI‑2002 during a scheduled PM and immediately saw cleaner encoder counts on our X‑stage. It seems to be more tolerant to EMI than our previous board.” — Production Engineer, display fab

Advantages & Value

- Reliability – Proven in 24/7 fabs; modules are stable over long duty cycles when kept within spec.

- Compatibility – Quadrature output fits most motion controllers; fiber link keeps the metrology signal quiet.

- Lower integration risk – Drop‑in replacement for ZMI 2000 systems minimizes requalification time in many cases.

- Support – We can assist with matching photoreceivers, laser sources, and environmental compensation options so the stack behaves as expected.

Installation & Maintenance

- Environment – Install in a ZMI 2000 chassis within a clean, temperature‑stable cabinet (good ventilation, low vibration, earth‑grounded).

- Wiring & fiber – Observe fiber minimum bend radius; route RS‑422 cabling away from motor power. Keep interferometer paths free of air turbulence when possible.

- Safety – ESD precautions during handling; power down the chassis and discharge before module insertion/removal.

- Upkeep – Periodic connector cleaning, verify quadrature phase at the controller, and apply firmware updates when recommended by the OEM.

- Calibration – System‑level calibration (e.g., wavelength/environmental compensation) should be checked after optics service or major layout changes.

Related / Supporting Components

- ZYGO ZMI 2000 Chassis – Required host backplane and AC input for ZMI‑series modules.

- ZYGO photoreceivers (e.g., 770x/771x series) – Heterodyne optical receivers that feed the ZMI‑2002 measurement channels.

- ZYGO laser source modules – Stable heterodyne laser heads sized for your path length and coherence needs.

- Environmental compensation modules – Temperature/pressure sensors to reduce refractive‑index error over long beam paths.

Quality & Certifications

- Manufacturer typically compliant with ISO 9001 quality systems

- CE marking and RoHS conformity at the system level (ZMI chassis and modules)

- 365‑day warranty from shipment date

- Traceable test reports available on request

If you’re replacing an existing board, you might notice that signal lock and quadrature stability come up quickly after install. We usually suggest a short run‑off test to verify counts per unit and direction mapping at the motion controller—simple step that saves time later.

Reviews

There are no reviews yet.