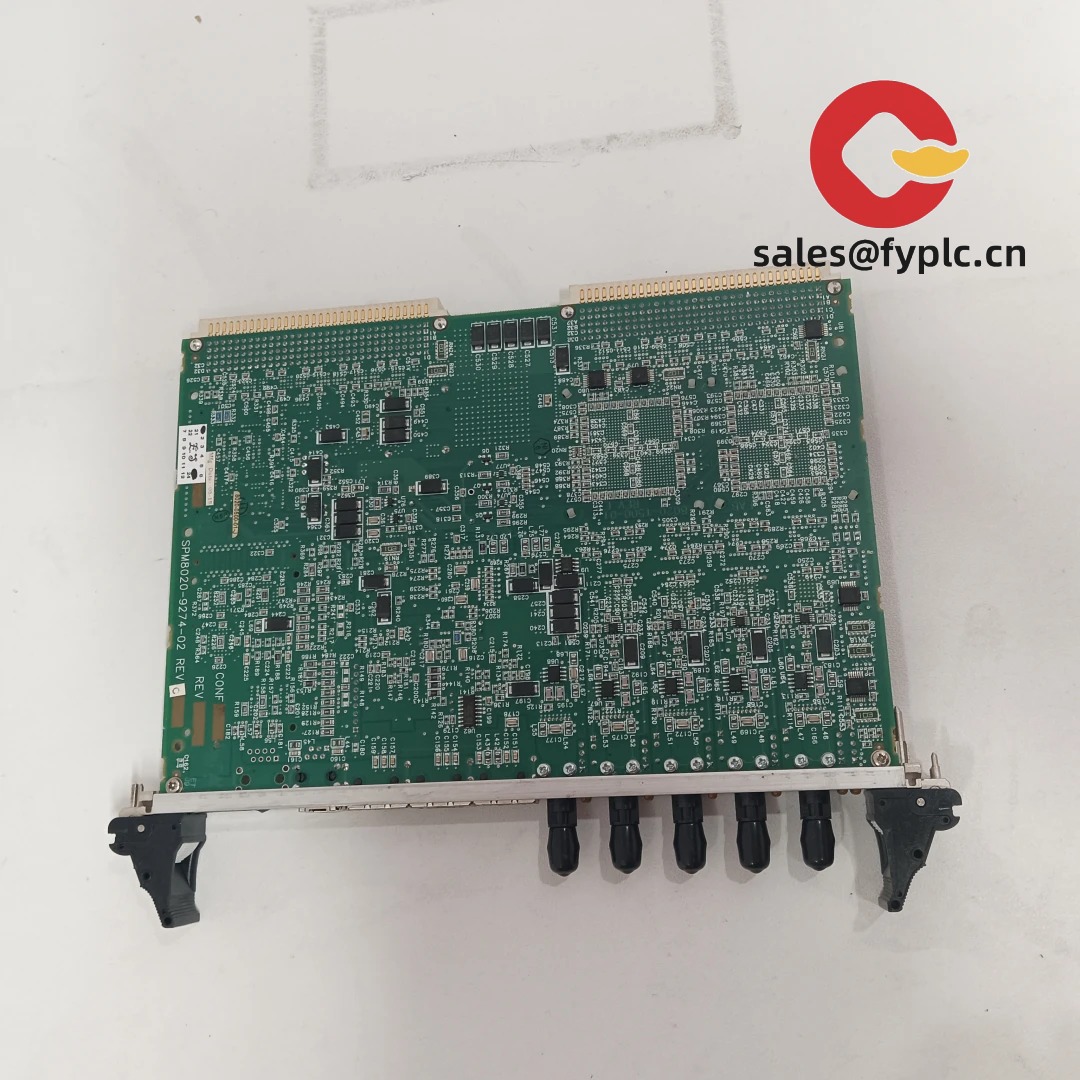

Description

ZYGO ZMI-4004 – Four-axis displacement measuring interferometer module for precision stage feedback

The ZYGO ZMI-4004 is a four-channel displacement measuring interferometer module designed for high-precision motion systems where nanometer-level position control is the daily standard. From my experience, this module sits at the heart of many semiconductor, precision optics, and advanced research tools—providing stable, synchronous metrology across up to four axes. It typically pairs with ZYGO heterodyne laser sources and interferometer optics (plane-mirror or corner-cube paths), giving you reliable, low-noise position feedback that most motion controllers can use without drama.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Four synchronized measurement channels – Measure and control X/Y/Z/θ or four linear axes with shared timing for tight multi-axis coordination.

- Nanometer-class resolution – Heterodyne interferometry typically delivers exceptionally fine resolution and repeatability for stage feedback.

- Stable long-term performance – The ZMI architecture is known for low noise and robust zero-drift behavior in controlled environments.

- Compatible optics – Works with ZYGO plane-mirror and retroreflector setups commonly used in wafer stages, alignment stages, and precision gantries.

- Controller-friendly outputs – Differential encoder-style outputs (A/B/Z) and synchronization signals simplify integration with industrial motion controllers.

- Scalable system topology – Add channels or configure axes as your machine grows; typically fits cleanly into a 19-inch metrology rack.

- Robust timing – Deterministic timing and latch/marker support help with high-throughput, closed-loop positioning.

Technical Specifications

| Brand / Model | ZYGO / ZMI-4004 |

| HS Code | 9031.49 (Measuring or checking instruments, optical – other) |

| Power Requirements | Typically +5 VDC from host chassis backplane; power draw is modest (module-level) |

| Dimensions & Weight | Module-sized board for 19″ rack systems; weight typically under 1 kg (varies by chassis) |

| Operating Temperature | 10 to 40 °C, non-condensing environment recommended for metrology-grade stability |

| Signal Input/Output Types | Interferometric measurement inputs for ZYGO optics/receivers; differential quadrature A/B/Z outputs; latch/marker/sync I/O (RS-422/TTL levels) |

| Communication Interfaces | High-speed differential encoder outputs to motion controller; auxiliary digital I/O for triggers; Ethernet typically via system gateway where used |

| Installation Method | Rack-mounted in a metrology cabinet or 19″ chassis; connects to ZYGO laser source and interferometer optics |

Note: Specific figures can vary by chassis revision and system configuration. If you share your current setup, we can confirm exact electrical and mechanical compatibility before shipping.

Application Fields

- Semiconductor lithography and inspection stages needing multi-axis nanometer control

- Ultra-precision optics fabrication and alignment benches

- Coordinate and metrology systems, including air-bearing and granite stages

- Research labs requiring stable, synchronized displacement readout across several axes

- High-end motion platforms in data storage, MEMS, and micro-assembly lines

A customer in wafer inspection told us they transitioned from two dual-axis modules to a ZMI-4004 and immediately simplified sync and cabling; their controller saw cleaner A/B/Z timing and better cycle-to-cycle repeatability, especially during step-and-settle moves.

Advantages & Value

- Reliability – Proven ZYGO heterodyne architecture with predictable thermal behavior in most lab and cleanroom environments.

- Compatibility – Encoder-like outputs typically drop into existing motion controllers, reducing integration time and risk.

- System simplicity – Four axes on one module can reduce chassis slot count, wiring, and spare parts complexity.

- Cost control – Consolidated channels and shared timing often result in less rework and shorter debug cycles.

- Technical support – We can help confirm optics paths, mirror types, and cabling so you get expected resolution from day one.

Installation & Maintenance

- Cabinet and environment – Mount in a grounded 19″ cabinet with good airflow; keep the measurement path in a low-vibration, thermally stable area (cleanroom conditions are ideal).

- Wiring and grounding – Use shielded cables for detector and encoder outputs; maintain single-point grounding to minimize noise coupling.

- Optics setup – Align plane-mirror or corner-cube optics carefully; verify beam path quality and return signal before closing the cabinet.

- Safety – Follow laser safety practices for Class II/III sources; secure beam paths and use appropriate eyewear when open.

- Routine maintenance – Periodically clean optics in a controlled environment, verify cable integrity, and check position counts and interpolation against a reference artifact at planned intervals.

- Firmware/parameters – Where applicable, keep firmware aligned across modules and back up calibration constants and axis parameters after any service.

Quality & Certifications

- CE and RoHS compliance typically applicable for ZYGO metrology modules and accessories

- Manufactured under ISO 9001 quality systems

- Warranty: 365 days (repair/replace, subject to evaluation)

Common Companion Parts (for planning)

- ZYGO heterodyne laser source (various models; specify wavelength and output)

- Plane mirror interferometer optics or corner-cube retroreflectors

- Receivers/detectors and beam delivery hardware suited to your axis geometry

- Shielded encoder-output cabling to the motion controller

If you share the motion controller model and axis lengths, we can recommend an exact optics path and confirm the ZMI-4004 channel allocation, cable lengths, and mounting details before you place the order. You might notice that getting these details clear up front usually shortens commissioning by a week or more.

Reviews

There are no reviews yet.