Description

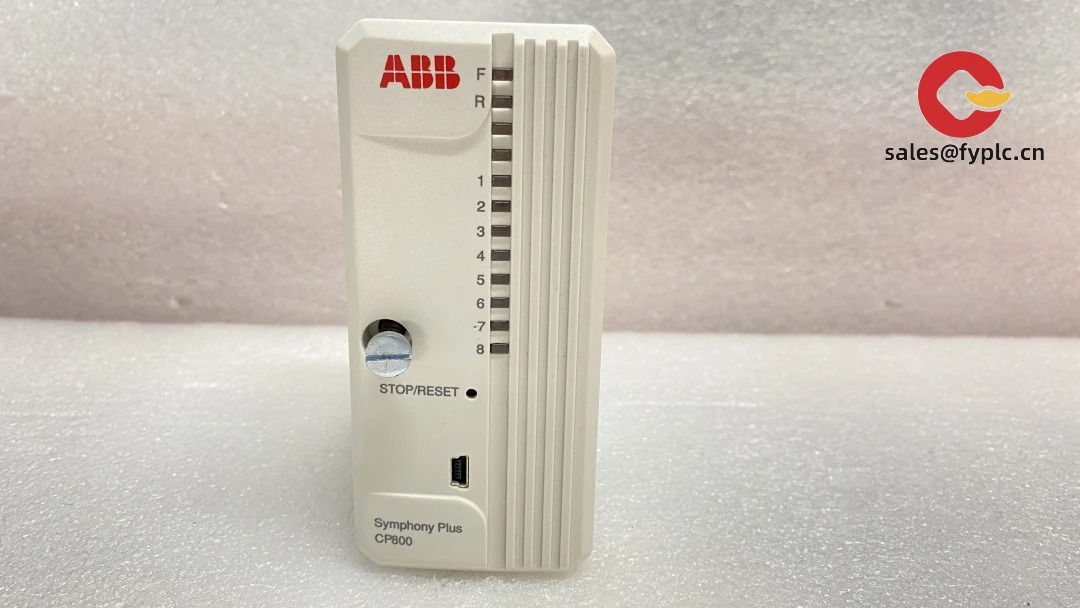

CP800 Industrial HMI Operator Panel – Streamlined Machine Interface for Modern Lines

The CP800 is designed as a compact, 8-inch class operator interface panel for production machinery, utilities, and process skids. From my experience, it’s a sweet spot for OEMs and retrofit teams who need a reliable, panel‑mount HMI that speaks common PLC protocols without getting overly complex. You might notice that it focuses on practical connectivity—Ethernet plus serial—and a front panel that typically meets IP65 for shop-floor environments.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week for in‑stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- 8-inch class touchscreen – A comfortable viewing area for machine status, alarms, and basic trends without taking too much panel space.

- 24 VDC power – Typically powered from the machine’s control supply for straightforward wiring.

- Industrial-grade front protection – Front panel typically IP65 when properly installed, suitable for dusty shop floors and light washdown.

- Versatile connectivity – Ethernet 10/100 plus RS‑232/RS‑485 for common PLCs; USB for project transfer and data logging.

- Protocol coverage – Works in many cases with Modbus RTU/TCP and, depending on project setup, can link to Siemens, Allen‑Bradley, Omron, or Mitsubishi controllers via standard drivers.

- Panel‑mount installation – Rear mounting clamps for fast cut‑out installation; keeps the cabinet door clean and serviceable.

- Data logging and alarms – Trend displays, alarm history, and recipe handling typically supported for operator efficiency.

Technical Specifications

| Brand / Model | CP800 (industrial HMI operator panel) |

| HS Code | 8537.10 – Boards, panels, consoles for electric control (≤1000 V), typical classification for HMIs |

| Power Requirements | 24 VDC (typical range 10–28 VDC) |

| Dimensions & Weight | 8-inch class panel; panel cutout typically around 192 × 138 mm; approx. 1.0–1.5 kg (varies by configuration) |

| Operating Temperature | 0 to +50°C (non‑condensing, typical spec for cabinet‑mounted HMI) |

| Signal Input/Output Types | 1× Ethernet 10/100; 1–2× RS‑232/RS‑485 serial; 1–2× USB (host/device); optional microSD for data/logs |

| Communication Interfaces | Modbus RTU/TCP; common PLC drivers (Siemens/AB/Omron/Mitsubishi); some projects enable OPC UA where licensed |

| Installation Method | Panel mount with rear clamps; front bezel typically IP65 when properly gasketed; VESA 75 mm often available |

Application Fields

The CP800 fits well in small to mid-size machines: metal forming presses, packaging equipment, dosing systems, and HVAC utilities. One thing I appreciate is how it simplifies retrofits—swapping older text displays for a color touch panel with Ethernet is usually straightforward. In many cases, OEMs deploy it on conveyor cells to visualize OEE counters and quick fault diagnostics. A maintenance lead recently mentioned, “We put three CP800s on a wash-down line, and operators finally stopped opening the cabinet to reset faults—everything is on-screen now.”

Advantages & Value

- Reliability – Stable 24/7 operation in cabinets; fewer nuisance reboots than low-cost tablets.

- Compatibility – Broad driver support reduces engineering time when mixing PLC brands across lines.

- Cost savings – Typically lower lifecycle cost versus PC‑based HMIs; no rotating media and simpler maintenance.

- Scalable deployment – Common project files and reusable screens help standardize HMIs across multiple machines.

- Support – We assist with model selection, protocol mapping, and on‑hand spares planning for smoother commissioning.

Installation & Maintenance

- Cabinet & mounting – Use a rigid panel per the cut‑out drawing; tighten rear clamps evenly. Keep the front gasket clean to maintain IP rating.

- Ventilation – Provide airflow in the enclosure; avoid hotspots near VFDs or power supplies. Operating range is typically 0–50°C.

- Wiring – 24 VDC with proper grounding; shield serial lines and segregate from high‑voltage conductors to reduce noise.

- Safety – De‑energize before servicing; verify lockout‑tagout. Use rated cables for Ethernet and serial ports.

- Routine care – Periodically back up the HMI project, clear old logs, and clean the screen with non‑abrasive wipes. Apply firmware updates where available to improve stability.

Quality & Certifications

Models in this class are typically produced under ISO 9001 quality systems and conform to CE and RoHS requirements. Many CP800 configurations also carry UL/cUL marks for control panels. The standard warranty is 365 days. If you need specific certificates or a test report for your compliance file, we can share them during quotation.

Reviews

There are no reviews yet.