Description

ABB Endura AZ20-112112221112E-STD – In-situ Zirconia O2 Analyzer for Combustion Efficiency and Safety

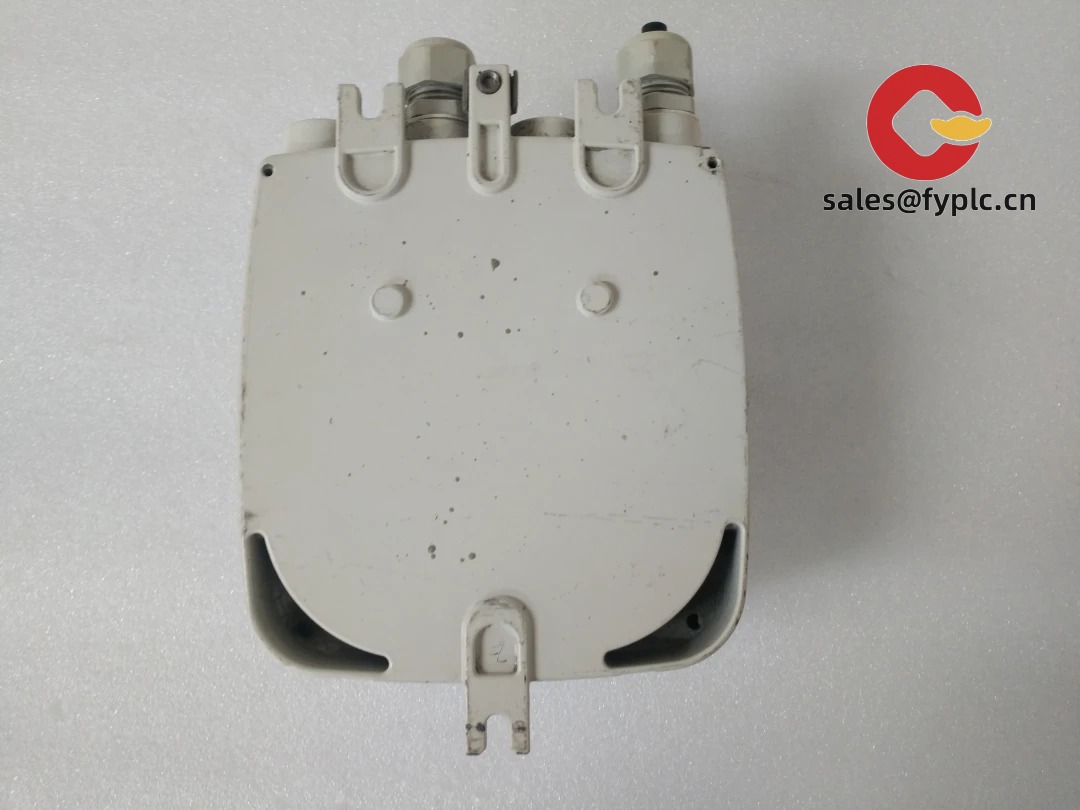

The ABB Endura AZ20 series is a proven in-situ zirconia oxygen analyzer designed for continuous flue gas O2 measurement right at the process. The code AZ20-112112221112E-STD appears to be a standard configuration variant, typically supplied with a sealed-reference zirconia cell, probe-style insertion, and integral electronics. From my experience, plants choose the AZ20 when they want fast oxygen feedback without the headaches of extractive sampling systems.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- In-situ zirconia measurement – Direct O2 sensing in the stack or duct, typically delivering faster response than extractive systems.

- Sealed reference cell (common on STD builds) – No instrument air required for reference; reduces utility and maintenance needs.

- High-temperature capability – Probe and sensor assembly designed for hot combustion gas streams; heater maintains stable cell temperature.

- 4–20 mA process output – Standard isolated analog output for DCS/PLC integration; HART often available for configuration and diagnostics.

- Rugged process wetted parts – Typically 316 stainless steel probe and sintered protection to handle corrosive flue atmospheres.

- Low drift, quick calibration – One- or two-point calibration using ambient air and certified gas; usually minimal downtime.

- Flexible mounting – Flanged penetration for horizontal or vertical stacks, with options for different insertion lengths.

Technical Specifications

| Brand / Model | ABB Endura AZ20-112112221112E-STD (in-situ zirconia O2 analyzer) |

| HS Code | 9027.10 (Gas or smoke analysis apparatus) |

| Power Requirements | 100–240 VAC, 50/60 Hz; heater-powered zirconia cell. Typical consumption in the 150–300 W range during heat-up, lower once stable. |

| Dimensions & Weight | Varies with probe length selected by the code; common insertion lengths are around 0.8 m to 1.5 m. Weight typically 8–12 kg for mid-length probes. |

| Operating Temperature | Ambient: approx. -20 to +55 °C for electronics; Process gas: commonly up to ~700 °C with high-temp probe options. Cell internally regulated near 700–800 °C. |

| Signal Input/Output Types | Analog: 4–20 mA O2 output (isolated). Discrete: typically 1–2 configurable relay/alarm outputs depending on variant. |

| Communication Interfaces | HART over 4–20 mA on many builds; local configuration via integral keypad/display where fitted. |

| Installation Method | In-situ probe, flange-mounted stack penetration (ANSI/DIN flanges based on order code), horizontal or vertical orientation. |

| Sensor Technology | Zirconia (ZrO2) oxygen cell with integral heater and porous protection. |

| Protection & Area Use | Industrial environments; hazardous area certifications are available on specific variants—confirm against the exact code string. |

Application Fields

You’ll typically see the AZ20 on combustion lines where O2 trim directly reduces fuel usage and improves safety:

- Utility and industrial boilers (gas, oil, biomass) for excess-air control

- Refinery and petrochemical process heaters and reformers

- Steel reheat furnaces, glass furnaces, and cement kilns

- Municipal and hazardous waste incineration

- Thermal oxidizers and regenerative thermal oxidizers (RTOs)

A maintenance supervisor at a cogen site told us, “Switching to in-situ O2 trimmed our gas use by a few percent almost immediately—what I appreciated was how much quicker it reacted after load swings.” That seems to be a common theme with direct, in-flue sensing.

Advantages & Value for Procurement

- Energy savings – Tight excess-air control can save 1–3% fuel in many cases, sometimes more on older burners.

- Lower maintenance footprint – No sample lines, chillers, or pumps; fewer failure points versus extractive analyzers.

- Reliable brand ecosystem – ABB spares, calibration kits, and long-term support help reduce lifecycle risk.

- DCS-friendly – Standard 4–20 mA and commonly HART make integration straightforward; minimal engineering overhead.

- Compliance and safety – Continuous O2 monitoring supports combustion safety interlocks and emissions objectives.

Installation & Maintenance Guidelines

- Mounting – Install on a suitable flange at a location with representative flue gas. Allow probe insertion length per the code, avoiding bends or impingement zones.

- Cabinet & wiring – If using a remote electronics option, place the transmitter in a ventilated cabinet to IEC/UL standards. Use shielded cable for 4–20 mA/HART, and route away from high-voltage sources.

- Ventilation and heat – Keep electronics within ambient ratings; avoid radiant heat from the duct. A weather hood is helpful outdoors.

- Safety – The probe tip runs hot; isolate the process and allow cool-down before removal. Use appropriate PPE and lockout/tagout procedures.

- Calibration – Perform routine checks with ambient air (span) and, if required, a certified zero gas (N2). Many users set quarterly checks; high-dust service may need more frequent attention.

- Cleaning – Inspect and gently clean the sinter/guard if ash or particulates accumulate; avoid harsh mechanical abrasion.

- Firmware & diagnostics – Where HART is available, use it to review live diagnostics and log calibration history. Update firmware when ABB releases stability improvements.

Quality & Certifications

- CE conformity for industrial emissions and safety directives (typical)

- RoHS compliance for materials, where applicable

- UL/cUL or equivalent electrical safety on specific electronics variants

- ATEX/IECEx hazardous area options available on certain codes—verify against AZ20-112112221112E-STD if required

- Manufacturer warranty: 12 months (365 days)

Common Accessories and Supporting Components

- Process mounting flanges (ANSI/DIN) with gaskets and isolation valve assemblies

- Weather hood and heat shield kits for outdoor or high-radiant-heat locations

- Calibration adapter and gas kits (ambient air check and nitrogen zero)

- Replacement zirconia cell/sensor and protection sinter

- Remote electronics cable sets (where remote head configuration is used)

If you’d like, share your burner type, fuel, duct temperature, and preferred flange standard. We can double-check the exact AZ20-112112221112E-STD options—probe length, wiring entry, and any hazardous area needs—so you get a drop-in part without surprises.

Reviews

There are no reviews yet.