Description

ABB AO2040 Analog Output Module – Precise 4‑Channel Control for PLC/DCS Loops

The ABB AO2040 is an analog output module designed for dependable 4–20 mA and 0–10 V reference signals in industrial control systems. From my experience, it fits well where you need stable commands to control valves, VFD reference inputs, positioners, dosing pumps, or heater power setpoints. One thing I appreciate is how modules like this simplify loop scaling and give you predictable, low‑noise outputs in many cases, even in dense cabinets.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- 4 analog output channels – Typically used to drive control valves, VFD references, or pneumatic positioners.

- Current and voltage modes – 4–20 mA or 0–10 V output ranges are commonly supported for flexible integration.

- 24 VDC cabinet power – Standard control power simplifies panel wiring and spares management.

- Backplane integration – Fits the ABB rack/terminal base of the respective I/O station; no external comm port needed.

- Channel diagnostics (basic) – You might notice basic status reporting for channel health in most configurations.

- DIN‑rail, cabinet‑ready design – Compact footprint for dense panels with standard wiring practices.

Technical Specifications

| Brand / Model | ABB AO2040 |

| HS Code | 853890 (Parts for switchgear, control panels and similar) |

| Power Requirements | 24 VDC nominal (typ. 18–30 VDC) |

| Signal Output Types | 4 channels; 4–20 mA and 0–10 V (software/group configurable in most systems) |

| Communication Interfaces | Backplane interface to ABB I/O rack; no front serial/Ethernet port |

| Operating Temperature | 0 to +55 °C (cabinet‑mounted; typical) |

| Installation Method | DIN‑rail on ABB terminal/base carrier within a grounded control cabinet |

| Dimensions & Weight | Compact I/O form factor; approx. 125 × 50 × 120 mm, ~0.25 kg (typical for this class) |

Application Fields

The AO2040 is typically deployed in process and factory automation where accurate setpoints are crucial:

- Process control loops: valve position control (I/P converters), dampers, actuators.

- Drives and motion: VFD analog reference (0–10 V or 4–20 mA), soft‑starter setpoints.

- Batch and dosing systems: pump speed control for chemicals, food & beverage, water treatment.

- Thermal applications: heater power reference, temperature cascade control to SCRs or controllers.

- Utilities and building systems: chilled water valves, AHU dampers, pressure controls.

A maintenance lead at a mid‑size chemical plant told us the module “stays stable across shifts; no drift we can notice, even when the cabinet warms up in summer,” which seems to be consistent with what we see in most cabinets with proper ventilation.

Advantages & Value

- Reliability under load – Steady outputs reduce loop hunting and nuisance trips.

- Compatibility – Works with standard 4–20 mA and 0–10 V field devices; easy to retrofit.

- Lower lifecycle cost – Standard 24 VDC power and off‑the‑shelf wiring accessories keep spares simple.

- Integration support – From my experience, backplane‑integrated I/O makes commissioning faster and cleaner.

Installation & Maintenance

- Cabinet standards – Mount on DIN‑rail inside a grounded, ventilated cabinet (IP54 or better is typical in dusty or humid areas).

- Wiring – Use shielded twisted pair for analog outputs; land shields at the cabinet end; segregate from high‑voltage/relay wiring.

- Power – Stable 24 VDC supply with proper grounding; consider separate PSU channel for analog I/O to reduce noise.

- Safety – De‑energize before insertion/removal; verify polarity and channel range (mA vs V) prior to commissioning.

- Maintenance – Periodic loop check and calibration verification every 6–12 months; keep terminals clean and torque‑checked.

- Firmware/parameters – If supported by the host system, keep I/O firmware and configuration backups updated after changes.

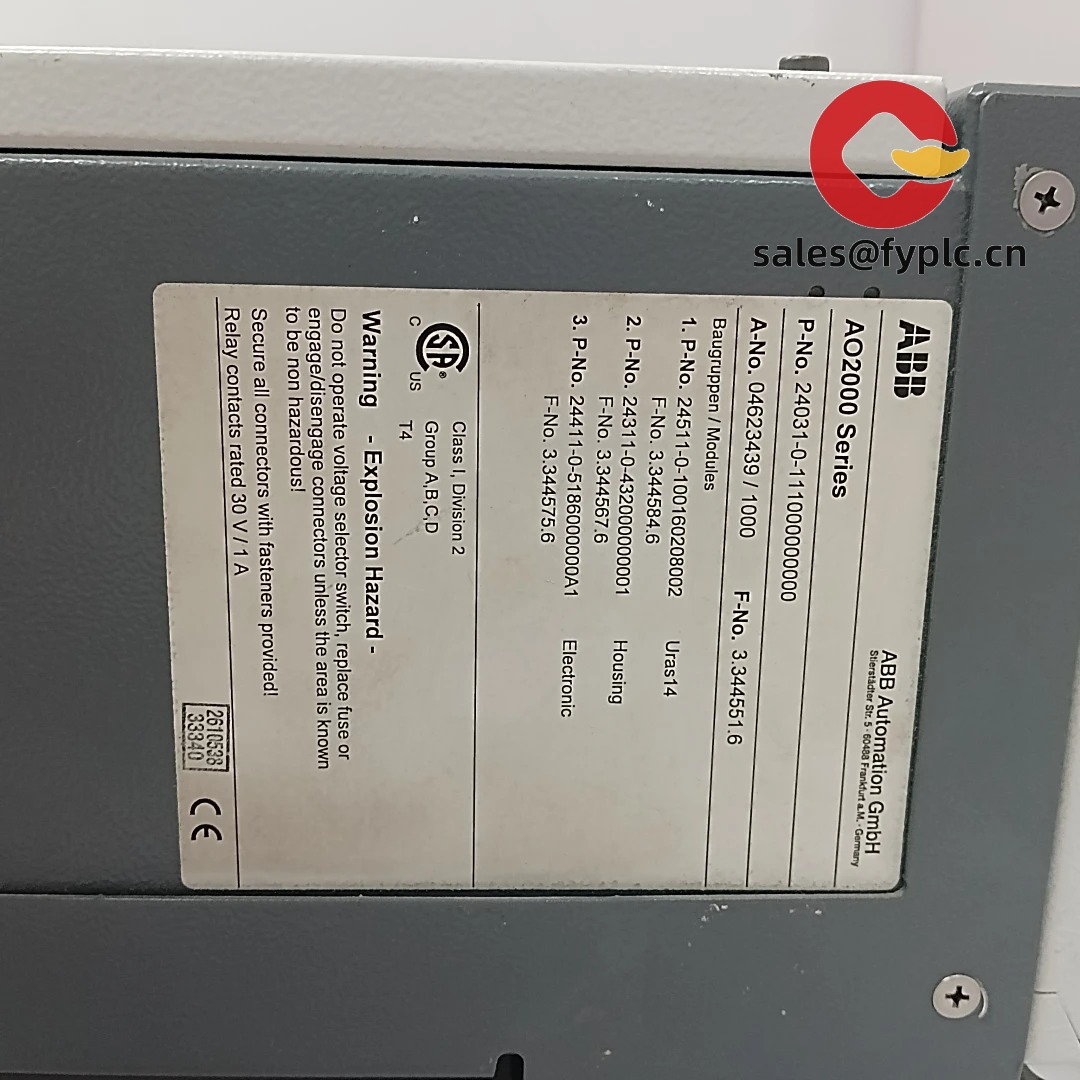

Quality & Certifications

- Manufacturer compliance typically includes CE and RoHS for industrial environments.

- UL/cUL recognition is common for ABB control I/O used in North America.

- Supply backed by a 365‑day warranty from us.

Related Accessories and Integration Notes

- Terminal/base carrier – Use the matching ABB backplane/terminal unit for your rack family; this provides power and field terminations.

- Power supply – 24 VDC industrial PSU with sufficient hold‑up and noise immunity is recommended.

- Field wiring – Pluggable terminal blocks and labeled ferrules reduce commissioning time and service errors.

- Isolation interfaces – Where long cable runs or mixed grounds exist, add analog isolators or signal conditioners as needed.

Reviews

There are no reviews yet.