Description

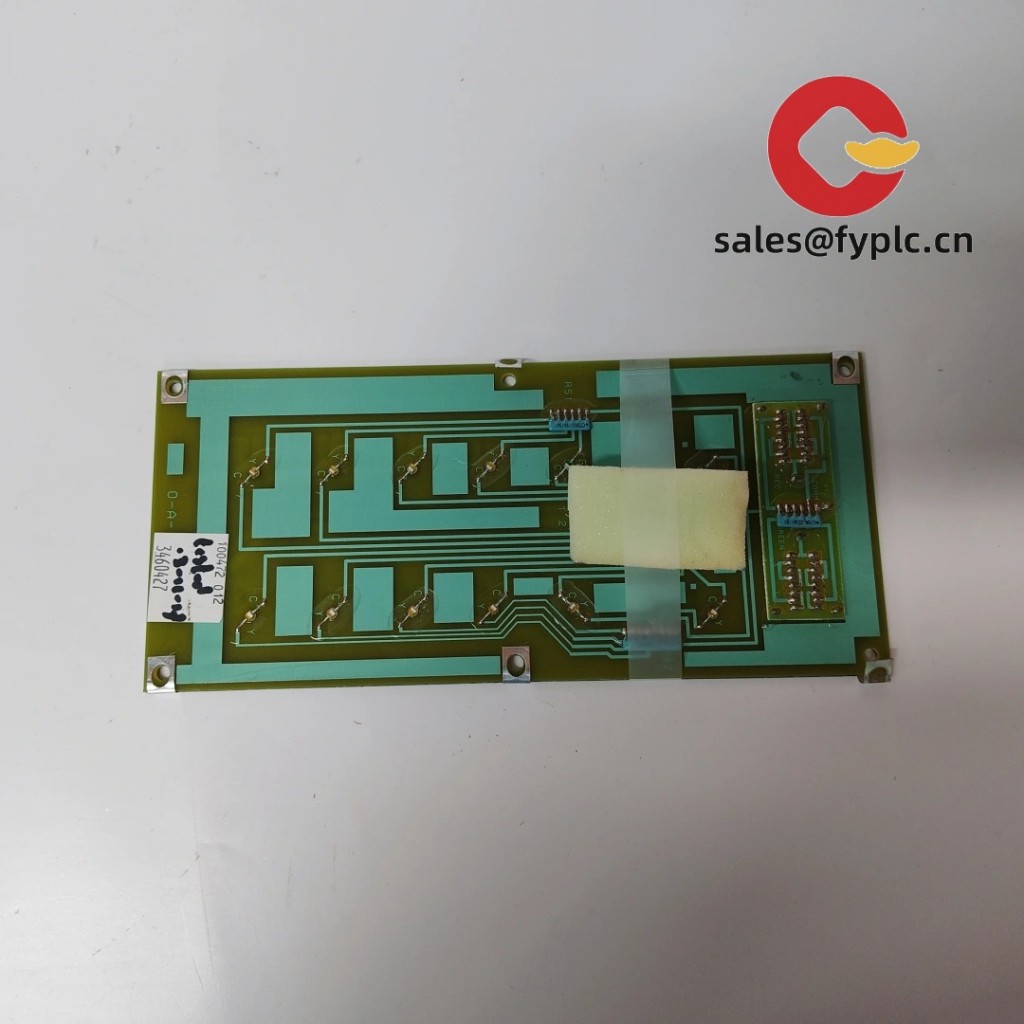

ABB 086339-001 – I/O Termination Assembly for INFI 90/Process Automation Cabinets

The ABB 086339-001 is commonly used as a passive I/O termination assembly in ABB Bailey INFI 90–style control systems, providing a clean, serviceable interface between field wiring and the controller I/O module. From my experience, plants choose this type of board when they need stable connections, organized wiring, and straightforward replacement during turnarounds—without touching the controller backplane.

You might notice that these termination assemblies make day-to-day maintenance a lot easier: wiring stays in the cabinet, modules can be swapped faster, and fault tracing is more practical with labeled terminals. It’s a small part that often saves hours during commissioning or an unexpected outage.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Passive field termination – No onboard power; designed to route signals from field devices to the paired I/O module reliably.

- Clean, serviceable wiring – Screw‑clamp terminals (in many cases) to keep wiring secure and inspection-friendly.

- Cabinet-friendly form factor – Typically mounts on DIN rail or backplate for quick access and tidy cable management.

- Compatible with ABB Bailey INFI 90 environments – Used widely in legacy modernization and ongoing maintenance programs.

- Shielded cable practices – Supports standard industrial shielding and grounding methods to reduce noise pickup.

- Low life-cycle cost – Simple construction means fewer failures and faster swap-outs during a shutdown.

Technical Specifications

| Brand / Model | ABB 086339-001 |

| HS Code | 8538.90 (Parts suitable for apparatus of headings 8535/8536/8537) |

| Power Requirements | Not powered (passive termination assembly) |

| Operating Temperature | Typically 0 to +60°C in a protected control cabinet; 5–95% RH non‑condensing |

| Signal Input/Output Types | Field wiring interface for discrete and/or analog channels depending on the paired I/O module |

| Communication Interfaces | None (signal termination only; no network ports) |

| Installation Method | DIN-rail or panel/backplate mounting; field wiring via screw terminals |

| Dimensions & Weight | Compact cabinet-mounted board; detailed outline drawing available on request |

Application Fields

The 086339-001 is typically found in:

- Refining and petrochemical units upgrading or maintaining ABB Bailey INFI 90 I/O

- Power generation and co‑gen plants standardizing cabinet terminations

- Pulp & paper and metals lines where tidy field wiring and fast changeouts matter

- Water/wastewater facilities consolidating legacy I/O and improving service access

A maintenance lead shared with us that replacing the termination assembly first—before touching any controller hardware—reduced downtime risk during an emergency DO card swap. That seems to be a recurring theme in brownfield sites.

Advantages & Value

- Reliability – Passive construction means very little to fail, especially in temperature‑stable cabinets.

- Compatibility – Designed for ABB Bailey INFI 90 environments; wiring conventions many technicians already know.

- Cost control – Keeps field wiring intact during module replacement, saving labor during turnarounds.

- Serviceability – Clear terminal layout supports faster loop checks and troubleshooting.

- Support – We can help confirm channel mapping to your exact I/O card revision, which in many cases avoids rework.

Installation & Maintenance

- Cabinet environment – Install in a clean, ventilated control cabinet (IP54 or better recommended). Avoid vibration and liquid ingress.

- Mounting – DIN‑rail or panel mount. Leave space for cable bend radius and service access.

- Wiring – Use ferrules for stranded conductors; torque terminals per standard practice. Maintain shield terminations and a single-point ground scheme.

- Safety – Isolate power to associated I/O modules and de-energize field circuits before any work. Verify zero energy and tag-out.

- Routine checks – Periodically re-torque terminals, inspect for discoloration or loosened shields, and clean dust using dry, oil-free air.

- Documentation – Keep an up-to-date channel map for the paired I/O module; it typically shortens fault-finding time.

Quality & Certifications

- Manufacturing quality – ABB production typically follows ISO 9001 quality systems.

- Compliance – CE marking applies at the system level; RoHS/UL status may vary by revision and intended market.

- Warranty – 365-day warranty coverage from shipment.

If you’d like, share your I/O card part number and the termination style you’re standardizing on (screw clamp, removable connector, etc.). We’ll verify fit and channel mapping before you place the order—this step, in most cases, prevents mismatches across cabinet rows.

Reviews

There are no reviews yet.