Description

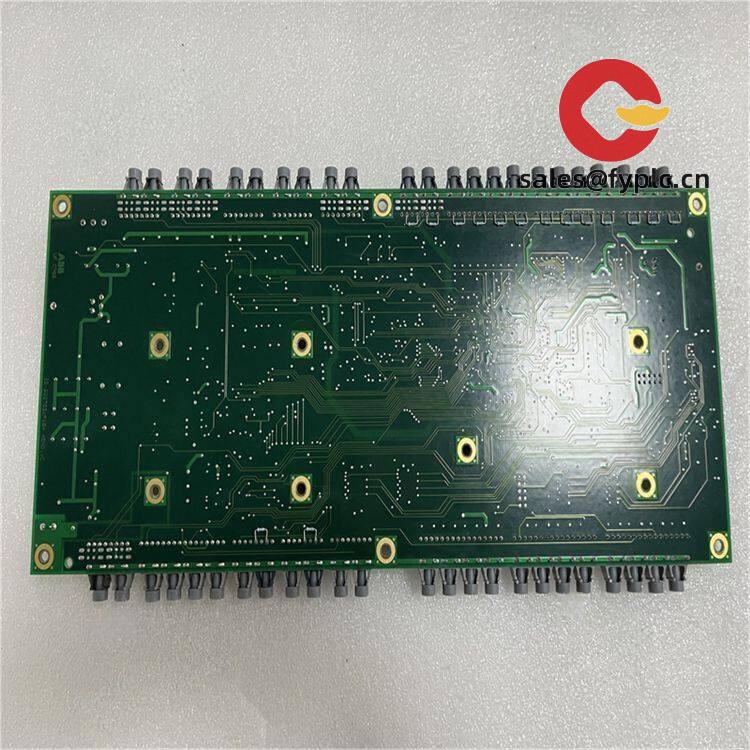

ABB UFC760BE143 (3BHE004573R0143) – Control Board for ABB Medium-Voltage Drive Systems

The ABB UFC760BE143, part number 3BHE004573R0143, is a control board widely used in ABB medium-voltage drive platforms. From my experience, it typically sits in the drive’s control rack to coordinate high‑speed signaling between the main controller and power sections. You might notice that sites running ACS1000 or ACS6000 families keep this board as a critical spare to minimize downtime—because when a control board fails, production stops fast. This module is designed as a direct plug‑in replacement, keeping wiring and parameterization straightforward in most cases.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week when in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

- Each unit is function-checked before dispatch, anti‑static packed, and traceable by serial/lot

Key Features

- Drive control coordination – Handles core control tasks between the main CPU and power electronics, helping keep MV drives stable under load.

- Fiber‑optic links – In many cases, the board provides fiber channels to gating units or power cells for noise‑immune communication in high‑EMI cabinets.

- Backplane integration – Plug‑in design for ABB control racks; it seems to be a straight swap during maintenance with minimal rewiring.

- Diagnostics support – Status LEDs and service-port access typically help technicians verify link, sync, and board health quickly.

- Robust build for industrial environments – Designed for continuous operation in MV drive enclosures with controlled ventilation.

- Lifecycle fit – Often used as a field-proven spare for ABB ACS1000/ACS6000 fleets where downtime costs are high.

Technical Specifications

| Brand / Model | ABB UFC760BE143 |

| Part Number | 3BHE004573R0143 |

| Functional Role | Drive control board for ABB MV drive control racks (commonly in ACS1000 / ACS6000 systems) |

| HS Code | 853890 (Parts for electrical control/switchgear) |

| Power Requirements | Supplied via drive backplane; typically low‑voltage DC (5 V / 24 V distribution within cabinet) |

| Operating Temperature | 0 to +55 °C typical for control boards installed in ventilated enclosures |

| Signal Input/Output Types | Backplane system bus, discrete status lines, fiber‑optic channels to power/gate units (model‑dependent) |

| Communication Interfaces | Fiber‑optic links; service/maintenance access typically via front connector; internal backplane bus |

| Installation Method | Plug‑in PCB for ABB control rack; secured with guide rails and screws |

| Dimensions & Weight | Board‑level module; typical control‑board footprint for ABB UFC series; approx. 0.4–0.6 kg |

Application Fields

This module is commonly deployed in:

- Metals and mining – MV fan, pump, and mill drives where uptime is critical

- Cement and minerals – Kiln, ID/FD fan, and conveyor drive control

- Oil & gas / Petrochem – Compressor and process pump drives with high EMI

- Power generation – Boiler feed pumps, cooling water pumps, and auxiliaries

A maintenance manager recently told us the board swap took under an hour, and the drive synced back on fiber without parameter changes—exactly the kind of low‑risk service window plants prefer.

Advantages & Value

- Reliability – Field‑proven in continuous‑process environments; stable operation with MV drive cabinets.

- Compatibility – Drop‑in fit for ABB racks using UFC760 series boards, reducing retrofit risk.

- Cost savings – Fast replacement prevents extended downtime; no re‑engineering in most cases.

- Technical support – Guidance on board handling, firmware/parameter alignment, and commissioning checks.

Installation & Maintenance

- Environment – Install in a clean, ventilated control cabinet; maintain cabinet temperature within 0–55 °C; avoid condensation.

- Mounting – Power down and lock out the drive; observe ESD protection; slide into guide rails, seat the backplane connector firmly, and secure screws.

- Wiring/Links – Verify fiber‑optic polarity and cleanliness; check backplane connectors for bent pins; confirm grounding integrity.

- Commissioning – Match firmware or parameter set to the drive’s configuration where applicable; run self‑tests and link/LED diagnostics.

- Routine care – Quarterly cabinet cleaning; inspect fibers and connectors; keep a known‑good spare; back up drive parameters after changes.

Quality & Certifications

- Typically conforms to CE requirements for industrial control equipment

- RoHS compliant components, lead‑free assembly where applicable

- Manufactured under ISO 9001 quality systems

- Warranty: 365 days replacement/support from shipment date

Related/Supporting Components

Plants often pair this board with other ABB UFC760 revisions (e.g., UFC760BE142 / 3BHE004573R0142 or UFC760BE144 variants) and compatible fiber‑optic gate unit modules. If you’re standardizing spares across multiple MV drives, we can help verify interchangeability by serial and firmware level.

Reviews

There are no reviews yet.