Description

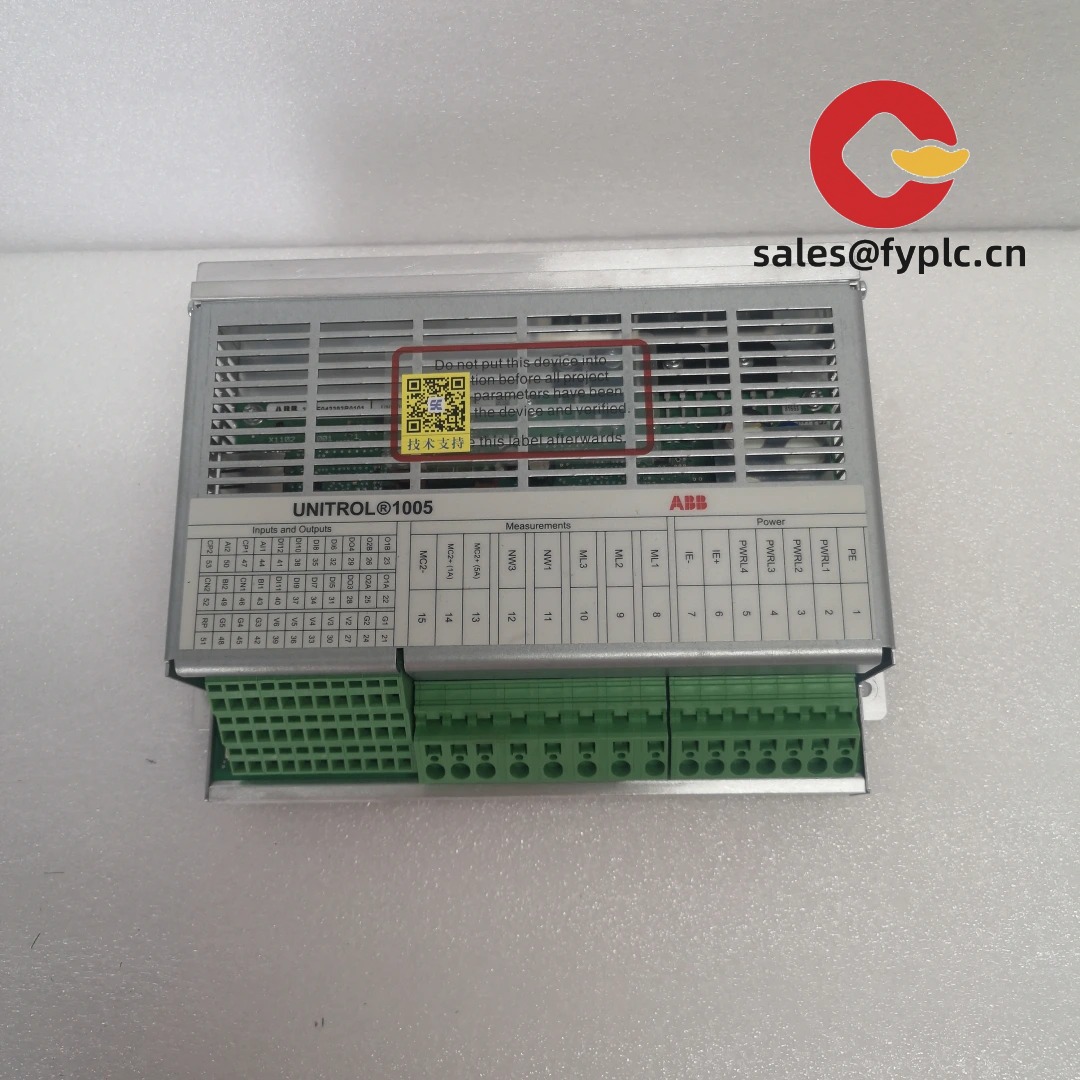

ABB UNITROL-1005-0011-ECO (3BHE043576R0011) – AVR controller board for reliable generator excitation management

The ABB UNITROL-1005-0011-ECO with part number 3BHE043576R0011 is a controller board in the UNITROL 1000 family, used for automatic voltage regulation (AVR) and excitation control of synchronous generators. From my experience, this model is picked when teams want a compact, field-proven AVR controller that interfaces cleanly with typical power plant auxiliaries and protection schemes. You might notice that the ECO build keeps the essentials—closed-loop voltage control, robust I/O, and stable firing logic—while staying cost-conscious for retrofit or multi-set projects.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Closed-loop AVR control – Stabilizes generator terminal voltage under varying load and power factor conditions.

- Integrated protection functions – Typically includes over/under-excitation limits and field overcurrent supervision to protect the exciter and generator.

- Flexible sensing – Voltage and current feedback channels for precise regulation, plus digital I/O for alarms, interlocks, and permissives.

- Service-friendly interface – Parameterization via service port and PC tool makes commissioning faster in many cases.

- Compact controller footprint – Saves cabinet space and simplifies retrofits on gensets and small-to-mid sized utility units.

- ECO variant – It appears that the ECO build focuses on core functionality with a streamlined BOM, helping reduce project cost without compromising control quality.

- Compatibility with UNITROL 1000 ecosystem – Works with standard ABB excitation accessories like power stages, field breakers, and signal transducers.

Technical Specifications

| Brand / Model | ABB UNITROL-1005-0011-ECO, Part No. 3BHE043576R0011 |

| HS Code | 903289 (Automatic regulating/control apparatus) |

| Power Requirements | 24 V DC (nominal), low-power controller consumption |

| Operating Temperature | Typically 0…55 °C (indoor cabinet environment) |

| Signal Input / Output Types | Voltage and current sensing inputs (generator feedback), analog/digital I/O for status and interlocks, firing/drive signals to excitation power stage |

| Communication Interfaces | Service/engineering port for parameterization; RS‑485/fieldbus options are commonly available on UNITROL 1000 systems |

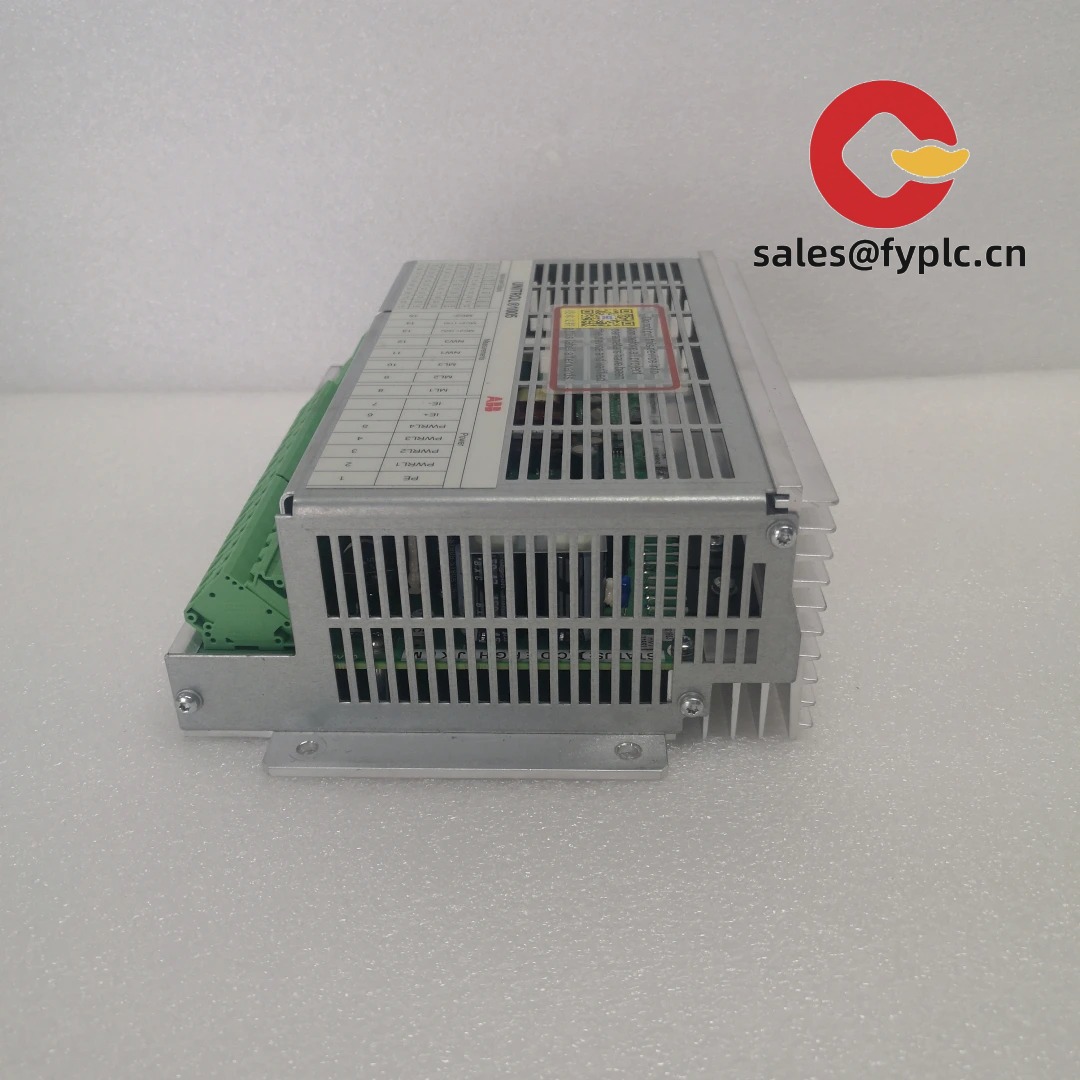

| Installation Method | Panel or cabinet mounting; pluggable terminals; install within a protected switchboard with proper ventilation |

| Dimensions & Weight | Compact controller card; typically under 1 kg. Refer to the UNITROL 1000 mechanical drawing for exact footprint. |

Application Fields

This controller is widely used in excitation systems for synchronous generators across:

- Industrial and commercial gensets (diesel or gas engine-driven)

- Small hydro units and islanded power systems

- Marine auxiliary generators and propulsion-related generators

- Cogeneration/CHP plants and peaking units

- Retrofit projects replacing legacy AVR boards while keeping the existing exciter hardware

Advantages & Value for Procurement

- Proven reliability – UNITROL 1000 controllers are known for stable regulation and low drift, which typically translates into fewer nuisance trips.

- Drop-in ecosystem fit – Compatible with ABB excitation accessories and standard plant interfaces, easing integration risk.

- Cost-effective ECO variant – Sensible pricing for fleet standardization or multi-unit rollouts without sacrificing core performance.

- Short lead and support – We target quick delivery and provide commissioning guidance to shorten outage windows.

A maintenance manager recently mentioned that swapping to this board cut their tuning time in half because the service tool made setpoint and limiter checks very straightforward.

Installation & Maintenance

- Cabinet standards – Mount inside a clean, dry, ventilated switchboard; maintain temperature within the specified range, typically 0…55 °C.

- Wiring – Use screened cables for sensing lines; keep power and signal wiring separated; verify polarity on VT/CT feedback.

- Grounding – Bond controller ground to the cabinet PE; avoid ground loops on measurement returns.

- Commissioning – Check generator nameplate values, set voltage setpoint, droop/PSS if used, and protective limiters before first energization.

- Routine maintenance – Visual inspection for dust and loose terminals each outage; clean with dry air; back up parameters after any change.

- Firmware & calibration – Update firmware when recommended by ABB; verify sensing calibration after major electrical work or VT/CT replacement.

- Safety – Lockout/tagout the exciter supply and field circuits; residual field energy can persist—discharge and verify before handling.

Quality & Certifications

- Conformity – CE marked; ABB manufacturing operates under ISO 9001 quality systems

- RoHS – RoHS compliant materials in most cases for electronic assemblies

- Warranty – 365-day warranty coverage

Recommended Supporting Components

To complete an excitation panel around UNITROL-1005-0011-ECO, we typically supply:

- ABB excitation power stage (thyristor/IGBT bridge) sized to the generator field current

- Field breaker/contactors and discharge resistors

- Voltage transformer (VT) and current transformer (CT) for sensing

- Human-machine interface (HMI) panel for local status and setpoint access

- RS‑485 cabling and surge protection for communication and remote monitoring

If you’re matching an existing ABB 3BHE043576R0011 footprint, share a quick photo of the panel and nameplate—one thing I appreciate is how consistent the wiring pinout tends to be across UNITROL 1000 variants, which usually keeps downtime to a minimum.

Reviews

There are no reviews yet.