Description

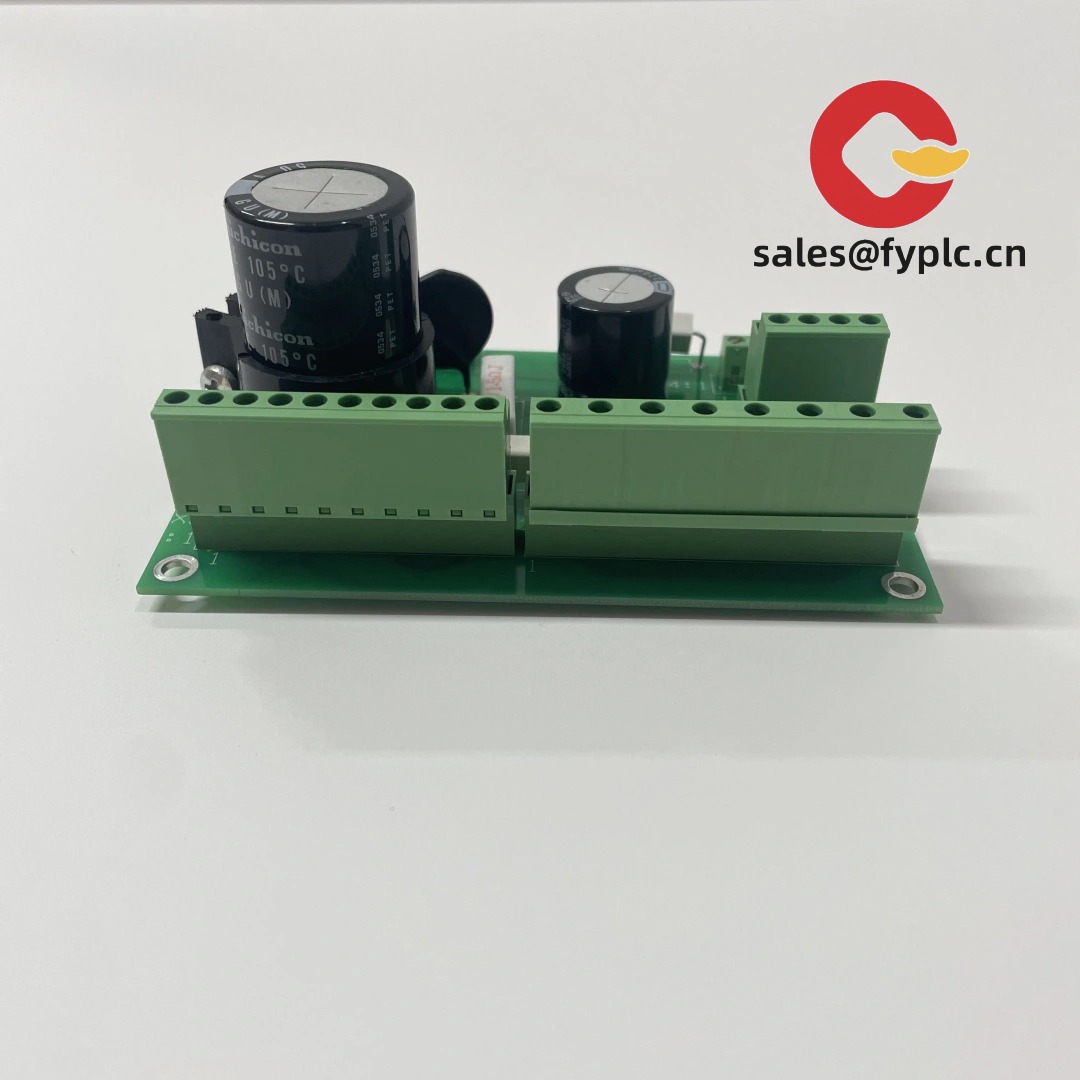

ABB 3ASC25H705-7 Control Board – OEM replacement PCB for ABB industrial systems

The ABB 3ASC25H705-7 is an OEM board-level spare designed to slot into ABB control or drive hardware that explicitly lists this part number in its bill of materials. From my experience, maintenance teams typically keep a unit like this on the shelf to cut downtime from days to hours—swap the board, run functional checks, and you’re back in production. You might notice that the “-7” suffix indicates a specific hardware revision, which helps with compatibility inside the same product family.

Order Placement Process and Guarantees

- Warranty: 365 days from delivery

- Lead time: typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance; full payment prior to delivery

- Express delivery options: FedEx, UPS, DHL

Key Features

- Genuine ABB part number 3ASC25H705-7 – OEM fit and function for systems that specify this board.

- Revision-specific (-7) – typically aligned with defined firmware and system compatibility baselines.

- Backplane-powered – no separate field power; simplifies cabinet wiring and replacement.

- Board-level spare – reduces MTTR by enabling fast swap instead of full module replacement.

- Factory-tested quality – units are typically delivered ESD-safe and function-verified.

- Traceability – labeled with part/revision so your maintenance records stay clean.

Technical Specifications

| Brand / Model | ABB 3ASC25H705-7 |

| Product Category | Control/Interface PCB Assembly (OEM spare) |

| HS Code | 853890 (Parts for electrical control equipment) |

| Power Requirements | Supplied via host backplane; typically 5 VDC logic level (no separate field power) |

| Operating Temperature | 0 to +55°C (typical control cabinet environment) |

| Signal I/O Types | Backplane bus and internal logic signals; no direct field I/O on the board |

| Communication Interfaces | Proprietary edge/backplane connectors; external fieldbus handled by the host unit |

| Installation Method | Insert into the designated slot or carrier; secure with screws/standoffs per service manual |

Application Fields

This board is applied as a replacement part inside ABB industrial control or drive systems where 3ASC25H705-7 is explicitly specified. In many cases it sits on a controller or power electronics assembly and handles internal logic/communication rather than direct field I/O. Typical environments include process lines, metals, pulp & paper, and motion/drive cabinets that run 24/7 and require predictable spares availability.

One thing I appreciate is how maintenance crews can standardize around the exact revision they have installed on critical lines. A customer in chemicals told me they cut a planned outage by half by staging this board and verifying firmware alignment ahead of time.

Advantages & Value for Procurement

- Compatibility confidence – OEM part number and revision (-7) align with ABB documentation and BOMs.

- Reduced downtime – drop-in board replacement is typically faster than module-level rewiring.

- Cost control – targeted board swap avoids replacing larger assemblies unnecessarily.

- Lifecycle support – traceable hardware helps plan spares and firmware strategies across sites.

- Technical support – verification assistance on part/revision fit before shipment, if needed.

Installation & Maintenance

- Cabinet environment – keep within 0–55°C, non-condensing humidity; ensure clean, dry air and adequate ventilation.

- ESD handling – use wrist straps, ESD mat, and keep the board in its protective packaging until installation.

- Power isolation – de-energize the host system and wait for DC bus discharge (for drive cabinets) before handling.

- Seating & fasteners – insert evenly into the backplane/connector; tighten mounting hardware to the specified torque.

- Wiring stress – route harnesses without tension; avoid pinching or sharp bend radii near the board edge.

- Post-replacement checks – run system self-tests, verify LEDs/diagnostics, and load matching firmware or parameters if the host requires it.

- Routine care – periodic dust removal with dry, oil-free air; keep firmware/config backups aligned with the installed revision.

Quality & Certifications

- Manufacturing quality system: ISO 9001 (manufacturer)

- RoHS: RoHS-compliant component in most cases

- CE/UL: compliance applies at the host equipment level; this board is an internal component

- Warranty: 12 months (365 days)

Related Supporting Components (commonly paired)

- Backplane or carrier for the controller/drive chassis – the mechanical seat and edge connectors for the 3ASC25H705-7.

- ESD-safe mounting hardware and standoffs – replacement fasteners to secure the PCB per ABB’s service guide.

- Firmware/configuration media – to align the host system with the installed hardware revision, when required.

If you share the exact host model or cabinet type, I can confirm fitment and advise whether any firmware alignment is typically needed with the -7 revision.

Reviews

There are no reviews yet.