Description

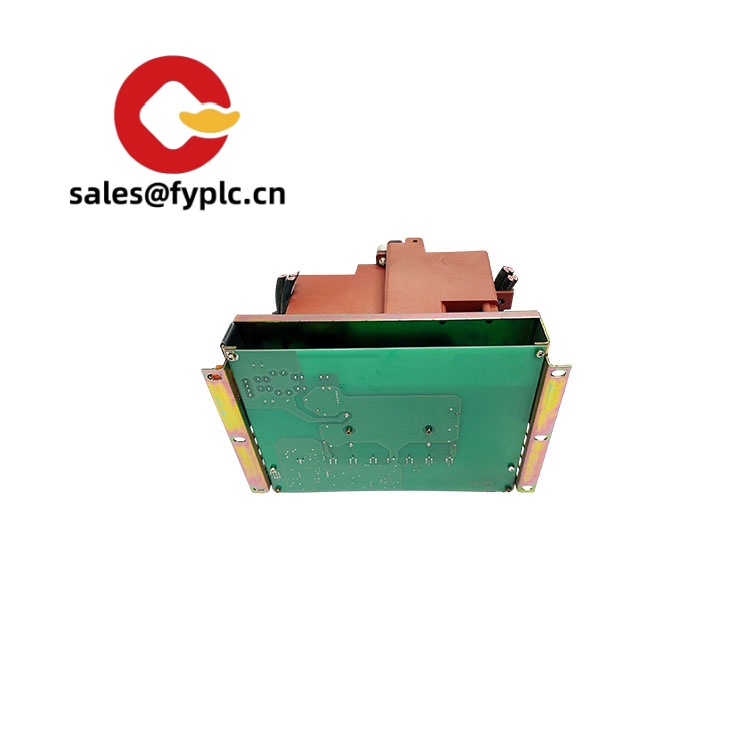

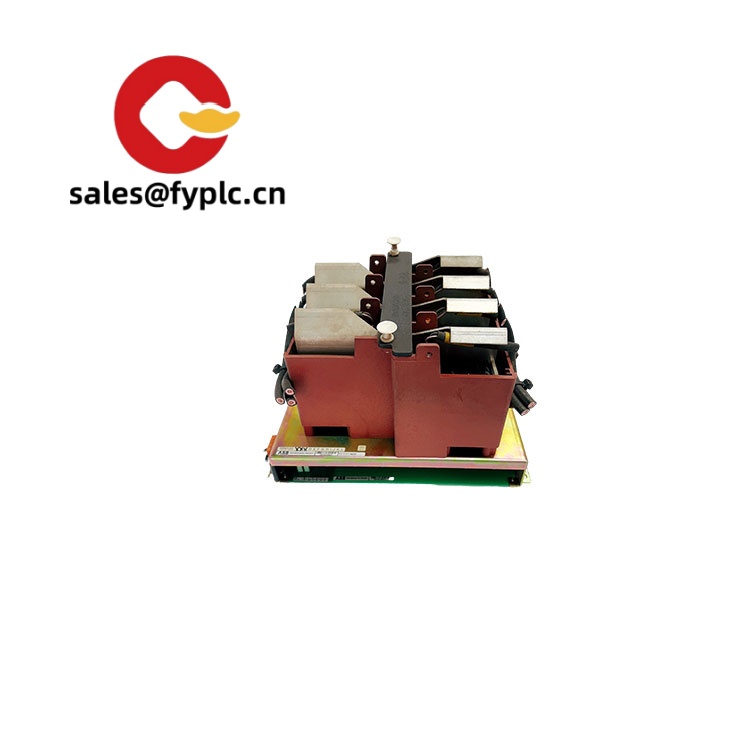

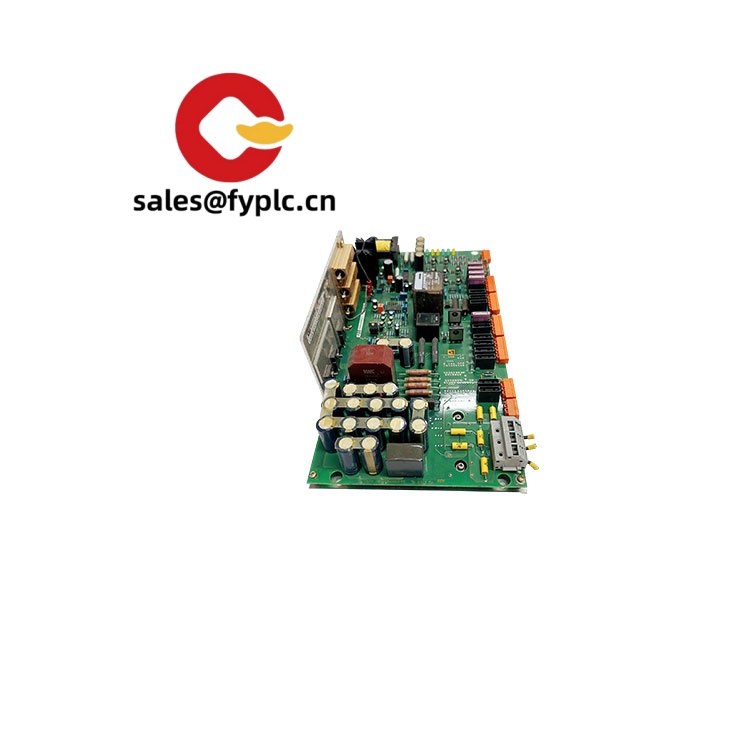

ABB KUC720AE01 with 3BHB003431R0101 & 3BHB000652R0101 – Control/Gate Unit Assembly for Medium-Voltage Drive Power Stacks

From my experience, the combination of KUC720AE01 with 3BHB003431R0101 and 3BHB000652R0101 shows up in ABB medium-voltage drive power stacks (commonly ACS1000/ACS3000 families) as the control and gate-drive section that manages IGCT/IGBT power devices via fiber-optic triggering. It’s typically specified during overhaul projects where phase gate units and the central control board must be replaced as a matched set to keep timings and protections aligned.

Our Order Process & Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance; full balance prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Matched control and gate-drive set – KUC720AE01 paired with 3BHB003431R0101 and 3BHB000652R0101 helps keep gating logic, interlocks, and protection timings consistent across phases.

- Fiber-optic gate triggering – You might notice the fiber links; that design reduces electrical noise coupling and improves immunity in high dv/dt environments typical of MV drives.

- Protection integration – Gate units usually supervise under-voltage, desaturation/fault feedback, and thermal trips, feeding status back to the KUC720-based control stage.

- Service-friendly – In many cases, boards can be swapped on-site with standard ESD practice; connectors and fiber pigtails are keyed to minimize errors.

- Designed for harsh cabinets – Typically specified to operate in drive cubicles with high electromagnetic stress, near power stacks and bus bars.

Technical Specifications

| Brand / Model | ABB KUC720AE01 + 3BHB003431R0101 + 3BHB000652R0101 |

| Product Type | Drive control board with associated gate/driver units (fiber-optic gating) |

| HS Code | 8504.90 (Parts of static converters) |

| Power Requirements | 24 VDC nominal for control/gate electronics (typical for ABB gate/control boards) |

| Operating Temperature | 0 to +55 °C (typical cabinet conditions for MV drives) |

| Signal Input / Output | Fiber-optic gate trigger outputs; fault/status feedback to the control board; backplane control signals |

| Communication Interfaces | Fiber-optic links to gate units; service/diagnostic access per board revision |

| Installation Method | Internal mounting within the ABB drive cabinet/power stack; secured on standoffs; fiber and low-voltage harness connections |

| Dimensions & Weight | Board-level assemblies; compact footprint; usually under 1 kg per board (varies by revision) |

| Typical Compatibility | Commonly used in ABB medium-voltage drives (e.g., ACS1000/ACS3000) with IGCT-based power stacks |

Application Fields

You’ll typically find this set in heavy-duty process applications where medium-voltage drives run critical equipment. A few real-world examples we’ve supported:

- Mine ventilation fans and hoists, where fiber-gated control keeps switching noise out of the control room.

- Cement kilns and large ID/FD fans, often during shutdowns where gate units are replaced in pairs or all three phases.

- Steel rolling mill auxiliaries and compressors, where stable gating improves torque control at low speeds.

- Water and wastewater MV pumps, especially in plants standardizing on ABB MV drive cabinets.

Advantages & Value

- Reliability – Using matched ABB board and gate units typically reduces nuisance trips and misfires, especially after maintenance.

- Compatibility – The KUC720AE01 works seamlessly with ABB fiber-optic gate units like 3BHB003431R0101 and 3BHB000652R0101 in many MV drive frames.

- Lifecycle savings – Pre-tested assemblies can shorten outage windows; one client in a cement plant cut restart time by roughly 30% after moving to like-for-like replacements.

- Technical backing – We help verify board revisions and phase mapping so you don’t end up mixing incompatible gate driver versions.

Installation & Maintenance

- Environment – Install inside the drive cabinet that meets ABB’s enclosure standards; maintain clean airflow and keep fibers away from tight bend radii.

- Wiring – Use the designated 24 VDC supply rails; confirm polarity and protective earth; route fiber-optic leads carefully to avoid stress and crossovers.

- Safety – Lockout/tagout; discharge DC link; apply ESD protection. Gate units should be handled by qualified MV drive technicians.

- Routine checks – Inspect fiber connectors for dust, verify gate enable/UVLO indicators, and review event logs after first power-up. Firmware/parameter alignment should match the drive type code.

- Spares strategy – In most cases, keeping a full phase set of gate units with one spare control board minimizes downtime during trips or planned shutdowns.

Quality & Certifications

- Manufactured to ABB quality standards for drive electronics; units are typically used in CE-marked systems.

- UL and RoHS compliance may depend on revision; we can confirm by the exact part label and revision code.

- Warranty provided: 365 days (repair/replace policy depending on fault analysis).

- Each shipment is function-checked where applicable; static-safe packaging and traceable labels included.

Related/Supporting Components

To round out a maintenance kit, customers often add:

- Fiber-optic patch leads rated for MV drive gating (phase A/B/C lengths as per cabinet layout)

- 24 VDC auxiliary power supply modules for gate/control electronics

- Thermal sensors and fault feedback harnesses tied to the power stack

- Cooling system spares (filters/fans) to keep the gate and control boards within temperature limits

One thing I appreciate is how predictable these sets behave when the revision codes match. If you share your drive type code and cabinet photo of the existing labels, we can double-check phase mapping and make sure KUC720AE01 with 3BHB003431R0101 and 3BHB000652R0101 slot in without parameter hassles.

Reviews

There are no reviews yet.