Description

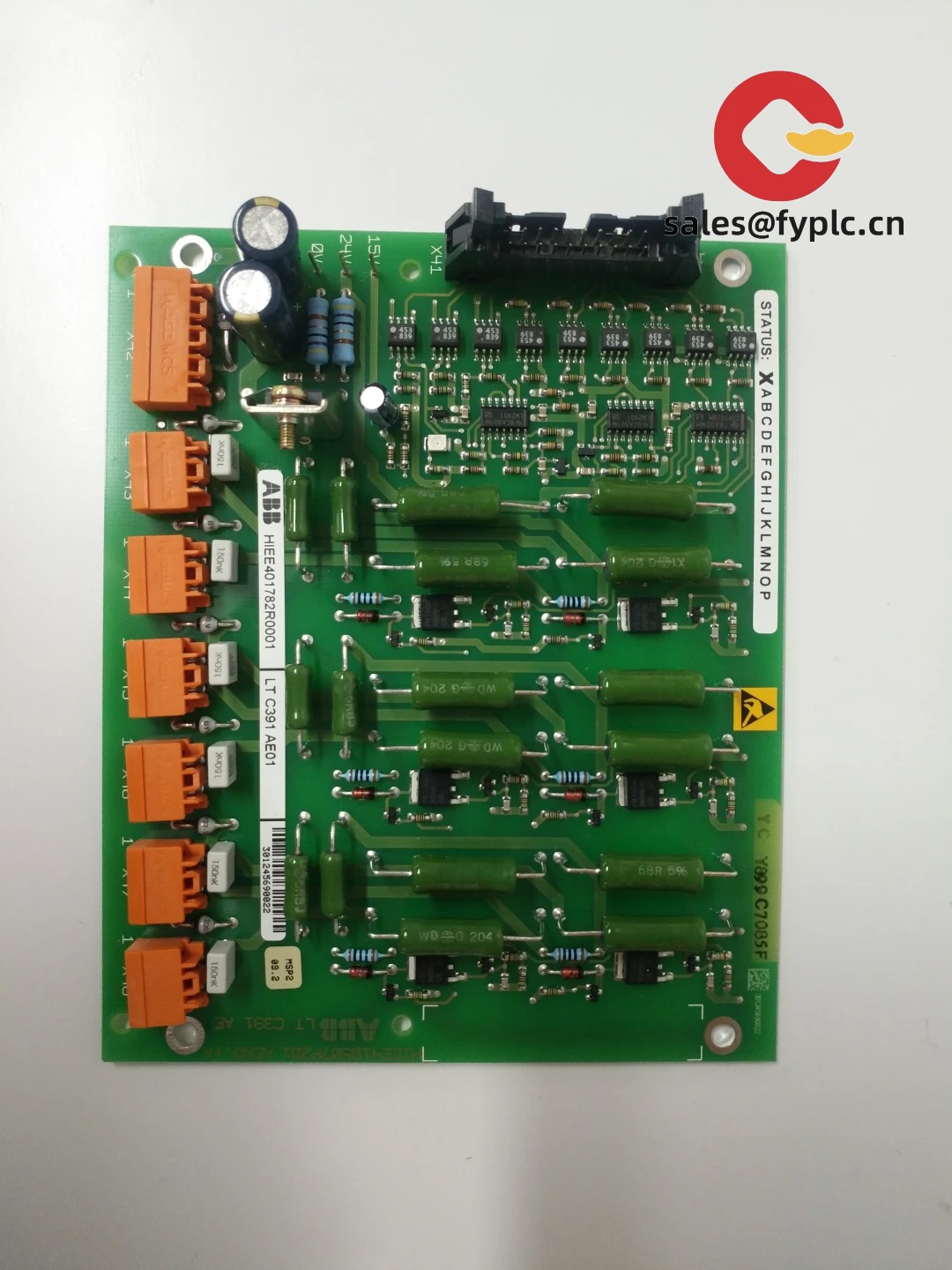

ABB LTC391AE01 (HIEE401782R0001) – Communication/Loop Controller Module for Symphony Plus / INFI 90 Racks

The ABB LTC391AE01 – ordering code HIEE401782R0001 – is a plug-in communication/loop controller module typically used within ABB Symphony Plus / INFI 90 systems. From my experience, engineers use it as a reliable backbone interface in node chassis, handling plant-network or loop signals and keeping legacy Harmony/INFI installations running smoothly. You might notice that the E01 revision tracking makes it easy to match firmware across a redundant pair or mixed system.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: In-stock items typically ship in 1 week; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Symphony Plus / INFI 90 compatibility – Designed to operate in ABB Harmony/INFI racks as a communication or loop controller module.

- E01 firmware/revision – Stable revision that, in many cases, simplifies matching against existing site configurations.

- Backplane-powered – No external power supply; it draws power directly from the system backplane for clean integration.

- Single-slot form factor – Standard INFI 90 mechanical footprint for quick slot-in replacement.

- Diagnostics indicators – Front-panel LEDs (typical for this series) aid in basic health checks and network status at a glance.

- Redundancy-friendly – Commonly used in redundant node designs to maintain uptime during switchover.

- Service/maintenance port – Often includes a front service port for local diagnostics, depending on sub-revision and site setup.

Technical Specifications

| Brand / Model | ABB LTC391AE01 – HIEE401782R0001 |

| HS Code | 8538.90 (Parts for industrial control apparatus) |

| System Compatibility | ABB Symphony Plus / INFI 90 node chassis (Harmony family) |

| Power Requirements | Backplane powered (no separate external supply; 5 V DC typical for this series) |

| Operating Temperature | 0°C to 60°C (typical operating range for similar ABB modules) |

| Signal I/O Types | INFI 90 backplane data; front-panel service/serial diagnostics (availability can vary by sub-revision) |

| Communication Interfaces | INFI-NET/plant network role; service RS-232 typical for maintenance |

| Installation Method | Plug-in single-width module; installs into an INFI rack slot with standard ejector/locking hardware |

| Revision | E01 |

Application Fields

Plants running ABB Symphony Plus / INFI 90 typically deploy the LTC391AE01 as part of their control network infrastructure. It seems to be most common in:

- Power generation (baseload and peaker stations with Harmony nodes)

- Oil & gas (upstream facilities and pipeline stations)

- Chemicals and petrochemicals (legacy unit controls and revamps)

- Pulp & paper (paper machine drives and process sections)

- Metals & mining (mill drives, material handling)

A maintenance lead at a combined-cycle plant told us they swapped an older communication card for an LTC391AE01 and it slotted straight in—no wiring changes—and the node re-synced within minutes. That’s the kind of low-risk upgrade teams look for.

Advantages & Value

- Drop-in replacement – Form-fit-function for INFI 90 racks reduces outage time and integration risk.

- Lifecycle support – Helps extend the useful life of installed Harmony assets without a full migration.

- Reliable operation – The E01 revision is known for stable behavior in most site conditions.

- Cost control – Avoids large-scale re-engineering; minimal commissioning effort in many cases.

- Procurement confidence – Units are function-tested with a 365-day warranty for peace of mind.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry control cabinet with adequate ventilation. Typical INFI racks meet these requirements.

- Handling – Observe ESD precautions; power down the rack before insertion/removal.

- Seating & wiring – Ensure connectors are fully seated. If a front service port is used, secure RS-232 cabling to avoid strain.

- Grounding – Verify rack grounding and shield terminations to minimize communication noise.

- Routine checks – Periodically inspect LED status, clean dust from front panel, and review network diagnostics.

- Firmware alignment – Match E01 revision across redundant pairs when possible to keep behavior consistent.

Quality & Certifications

- Certifications – CE compliant; UL for industrial control equipment is typical for this series; RoHS depends on production year.

- Manufacturer – ABB (Harmony / INFI 90 family)

- Warranty – 365 days

If you need confirmation against a specific rack type, node configuration, or firmware baseline, share the installed base details and we’ll verify compatibility before you place the order.

Reviews

There are no reviews yet.