Description

ABB PP865A (3BSE042236R2) – Rugged 15-inch HMI for reliable machine and process operation

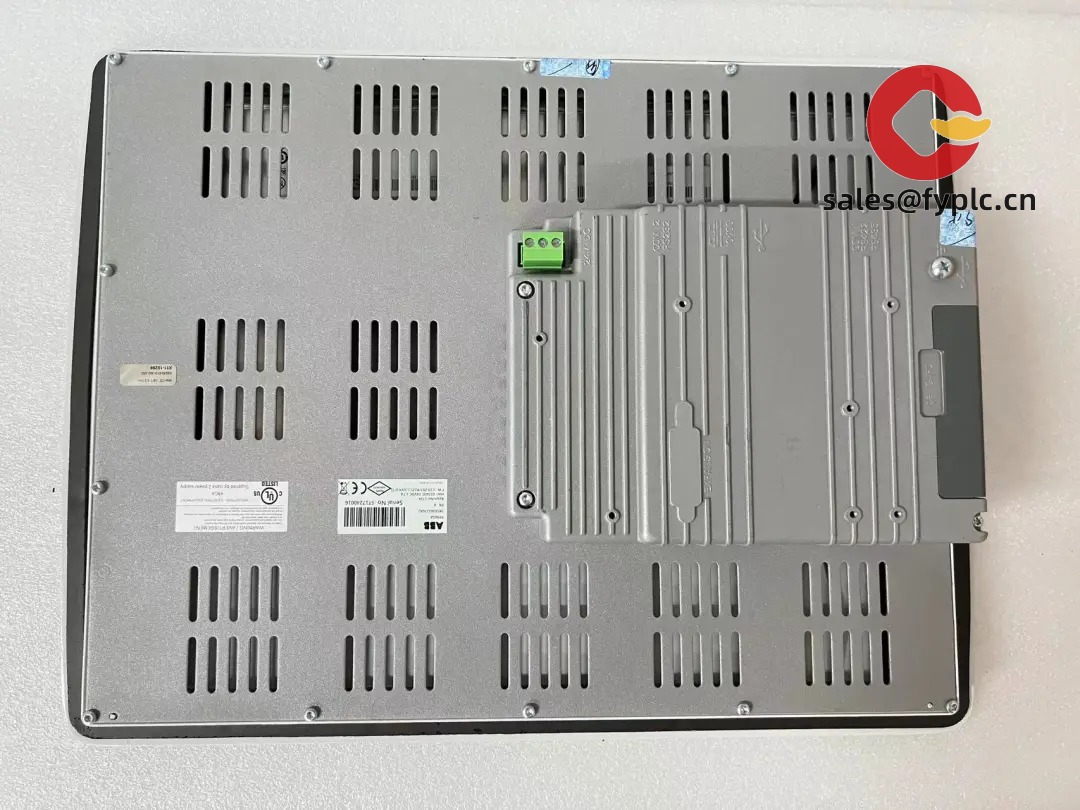

The ABB PP865A, order code 3BSE042236R2, is part of ABB’s Panel 800 series and is typically used as a 15-inch operator interface for machinery, lines, and process cells. From my experience, it’s a solid fit when you want a straightforward, panel-mounted HMI that talks cleanly to ABB controllers and most common third‑party PLCs over Ethernet or serial. You might notice that the front panel seals well against dust and splashes, which in many cases saves headaches on packaging, metals, and utilities lines.

Order Placement Process & Guarantees

-

- – Warranty period: 365 days

-

- – Delivery time: 1 week if in stock; no more than 1 month at the latest

-

- – Payment terms: 50% advance payment; full payment before delivery

-

- – Express options: FedEx, UPS, DHL

We test units prior to dispatch and package for industrial transit. For repeat orders, we usually lock in the same hardware revision unless you specify otherwise.

Key Features

- 15-inch TFT touch display – Clear operator views typically at 1024×768; good readability on the floor.

- Panel-mounted, IP65 front – Sealed bezel when properly installed; ideal for dusty or damp areas.

- 24 VDC supply – Standard control cabinet power; simple to integrate and service.

- Ethernet and serial connectivity – Communicates over 10/100 Ethernet plus RS‑232/485 for legacy devices.

- Broad driver support – Typically supports Modbus TCP/RTU, Ethernet/IP, and ABB controller drivers via Panel 800 runtime.

- Runtime stability – Usually runs Windows CE-based Panel 800 runtime; stable for 24/7 operations.

- Service-friendly design – Front access for cleaning; rear access for wiring; clear status LEDs to speed troubleshooting.

Technical Specifications

| Brand / Model | ABB PP865A (Order code: 3BSE042236R2) |

| HS Code | 8537.10 (Boards, panels, consoles for electric control, ≤1000 V) |

| Display | 15″ TFT touch, typically 1024×768, resistive touchscreen |

| Power Requirements | 24 VDC (±20%) |

| Operating Temperature | 0 to +50 °C (non-condensing); storage typically −20 to +60 °C |

| Signal I/O Types | Touch input; Ethernet comms; serial comms (RS‑232/485); USB for data/service |

| Communication Interfaces | 1× RJ45 10/100Base‑T; 1× RS‑232; 1× RS‑485; USB Host/Device (typical) |

| Installation Method | Panel mounting with clips; IP65 front when correctly gasketed |

| Dimensions & Weight | 15-inch class HMI; front bezel approx. ~400 × ~300 mm; depth < 65 mm; weight ~4–5 kg (typical) |

Note: Interfaces and minor details can vary by hardware revision; if you have a specific firmware or driver requirement, we can verify against your exact 3BSE042236R2 unit before shipping.

Application Fields

- Machine interface for packaging, material handling, and discrete assembly cells

- Process skids in water/W&WW, food & beverage, and fine chemicals

- Utilities dashboards (boilers, compressors, HVAC plant rooms)

- Line supervisory HMIs linked to PLCs via Modbus TCP or Ethernet/IP

A maintenance lead at a beverage plant told me the PP865A “just keeps running” and, more importantly, operators picked it up fast because pages are responsive and clear. That tends to reduce callouts during night shifts.

Advantages & Value

- Reliability – Built for continuous duty; fewer nuisance reboots and freezes in most cases.

- Compatibility – Works smoothly with ABB controllers and common PLCs; standard Ethernet and serial options simplify integration.

- Cost control – Panel-mounted form factor saves cabinet space and wiring time compared with panel PCs.

- Lifecycle support – Spares, firmware, and runtime licenses are typically straightforward to maintain across fleets.

Installation & Maintenance

- Cabinet & mounting – Install in a rigid panel per the cut-out drawing; ensure uniform gasket compression for IP65 at the front.

- Power & grounding – Supply 24 VDC via a regulated source; bond PE ground; segregate signal and power wiring to reduce noise.

- Ventilation – Maintain airflow in the enclosure; avoid direct heat sources. Operating temperature 0…50 °C.

- Wiring – Use shielded cables for RS‑485; keep Ethernet runs within recommended lengths; label ports to speed service.

- Routine care – Clean the bezel with a soft, non-abrasive cloth; back up application files; apply firmware/runtime updates during planned downtime.

- Spare strategy – For critical lines, keeping one spare PP865A on the shelf typically minimizes MTTR during unplanned events.

Quality & Certifications

- CE compliant; RoHS compliant

- UL/cUL listing for industrial control equipment (typical for Panel 800 family)

- Manufactured under ISO 9001 quality systems

- Seller warranty: 365 days

Supporting Components (commonly paired)

- 24 VDC DIN-rail power supply with sufficient headroom for HMI inrush

- Industrial Ethernet switch (managed, if VLANs/QoS are needed)

- Shielded RS‑485 cable and terminators for Modbus RTU segments

- Panel mounting kit and replacement gasket set for IP65 integrity

Next Steps

If you can share your runtime version or required drivers (e.g., Modbus TCP, Ethernet/IP, ABB specific), we’ll verify compatibility against PP865A 3BSE042236R2 stock and confirm the exact hardware revision and lead time. For replacement projects, a screenshot of the system info page is usually enough.

Reviews

There are no reviews yet.