Description

ABB PPD117A3011 (3BHE030410R3011) – Pulse/Driver Control Board for Converter and Drive Systems

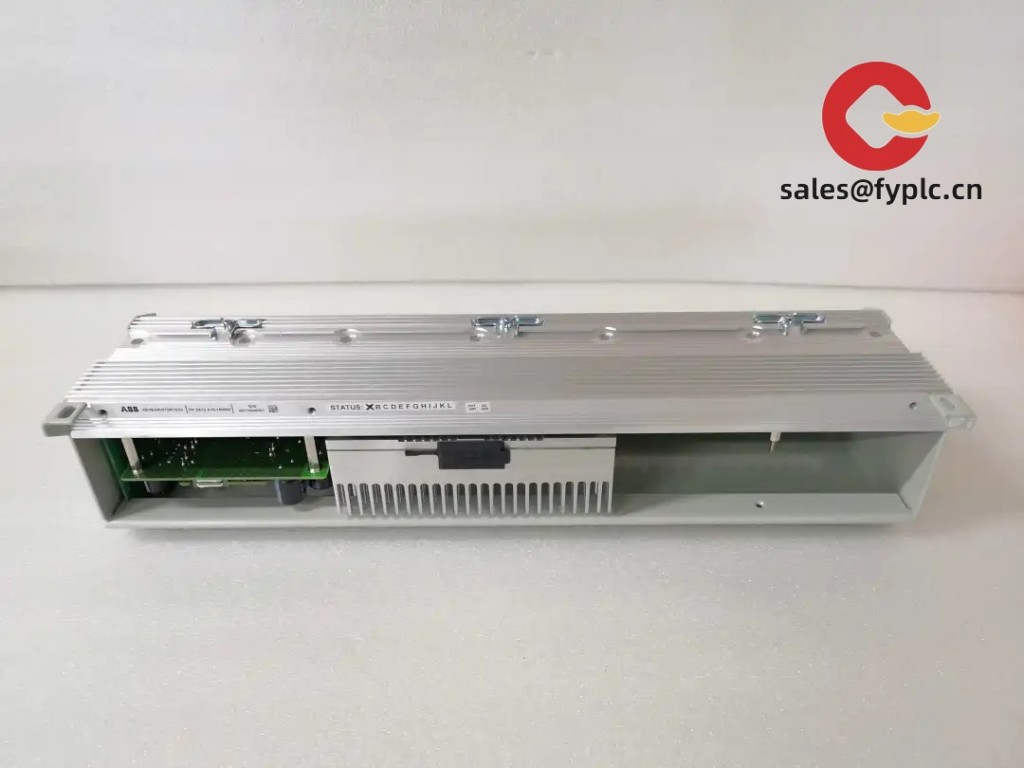

The ABB PPD117A3011, part number 3BHE030410R3011, is a control/pulse driver board typically used inside ABB converter cabinets and medium-voltage drive systems. It manages isolated trigger signals and interlocks between the main control and the power semiconductor stage, helping the drive start, stop, and protect itself in a predictable way. From my experience, this module is often specified as a replacement spare when plants want to restore OEM performance and keep drive availability high without re-engineering the cabinet.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: typically 1 week for in‑stock parts; no more than one month at the latest

- Payment method: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Isolated pulse/trigger outputs – Drives gate signals to the power stage with proper isolation for IGCT/IGBT stacks in many cases.

- Interlock and protection handling – Coordinates trips, ready signals, and permissives to ensure safe converter operation.

- Backplane integration – You might notice that it plugs into the cabinet subrack, communicating with the main control through a proprietary backplane or fiber links.

- OEM form/fit compatibility – Typically drop-in compatible with the designated ABB rack position, minimizing commissioning time.

- Stable timing and low jitter – Consistent firing timing that helps reduce stress on the power semiconductors.

- Service-friendly design – Status LEDs and test points (where fitted) simplify troubleshooting during outages.

Technical Specifications

| Brand / Model | ABB PPD117A3011 – 3BHE030410R3011 |

| Function | Pulse/driver control board for converter power stages (medium-voltage/industrial drives) |

| HS Code | 853890 (Parts suitable for switchgear/controls of 8535–8537) |

| Power Requirements | 24 VDC supply (typical), low power consumption < 5 W in most cases |

| Dimensions & Weight | Approx. 233 × 160 mm (Eurocard-style board); ~0.3–0.4 kg |

| Operating Temperature | 0 to +55 °C cabinet ambient (typical for control electronics) |

| Signal Input/Output Types | Isolated gate/trigger outputs; status and interlock inputs; backplane timing/control lines; fiber links on some builds |

| Communication Interfaces | Proprietary backplane and/or fiber optic interface; no external Ethernet/fieldbus on-board |

| Installation Method | Plug-in module for ABB converter/drive subrack; secured with card guides and front fasteners |

Application Fields

This board shows up most often in heavy-duty applications where drive reliability matters: steel and non‑ferrous rolling mills, mining hoists, tunnel/ID fans, large compressors and pumps, marine propulsion, and test benches. In many cases it’s stocked as a critical spare so that a single card swap can bring a downed converter back online without touching the power stack.

Advantages & Value

- Form-fit-function match – Keeps cabinet wiring and timing intact; no rework on harnesses.

- Short downtime – Swap-in replacement typically reduces MTTR from hours to minutes.

- Compatibility assurance – Revision checks to align with the installed converter generation.

- Lifecycle support – Suitable for installed-base maintenance where full drive replacement isn’t justified.

One thing I appreciate is the predictable behavior after installation—plants usually report a clean start once the interlocks are satisfied and parameter alignment matches the running cabinet. A maintenance lead told me they keep one PPD117A3011 on the shelf because it “saved two weekend shutdowns in a row.”

Installation & Maintenance

- Cabinet environment – Install in a clean, dry, ventilated cabinet. Maintain airflow; avoid dust buildup on connectors.

- Wiring and connectors – De‑energize the cabinet; observe ESD precautions. Seat the board fully in the subrack; verify backplane alignment and any fiber connections click in cleanly.

- Power – Confirm stable 24 VDC supply and correct polarity. Check fusing and common returns to minimize noise.

- Parameter/firmware alignment – Match board revision to the converter’s control level. In most cases, retain/set timing parameters as per the drive’s service manual.

- Routine care – Inspect annually for loose fasteners, oxidized edge contacts, and fan filter clogging in the cabinet. Clean with ESD-safe methods only.

- Safety – Wait for DC link discharge before handling. Lockout/tagout the feeder and verify zero energy state.

Quality & Certifications

- Manufactured under ISO 9001 quality systems (ABB production)

- RoHS-compliant materials, as typically applied to ABB control electronics

- CE/UL conformity at the system level; this board is an OEM component intended for use within certified assemblies

- 365-day warranty coverage

Note: Specific connector layout and firmware compatibility can vary by cabinet generation. If you can share the installed drive model and current board revision, we’ll verify interchangeability and set realistic lead times right away.

Reviews

There are no reviews yet.