Description

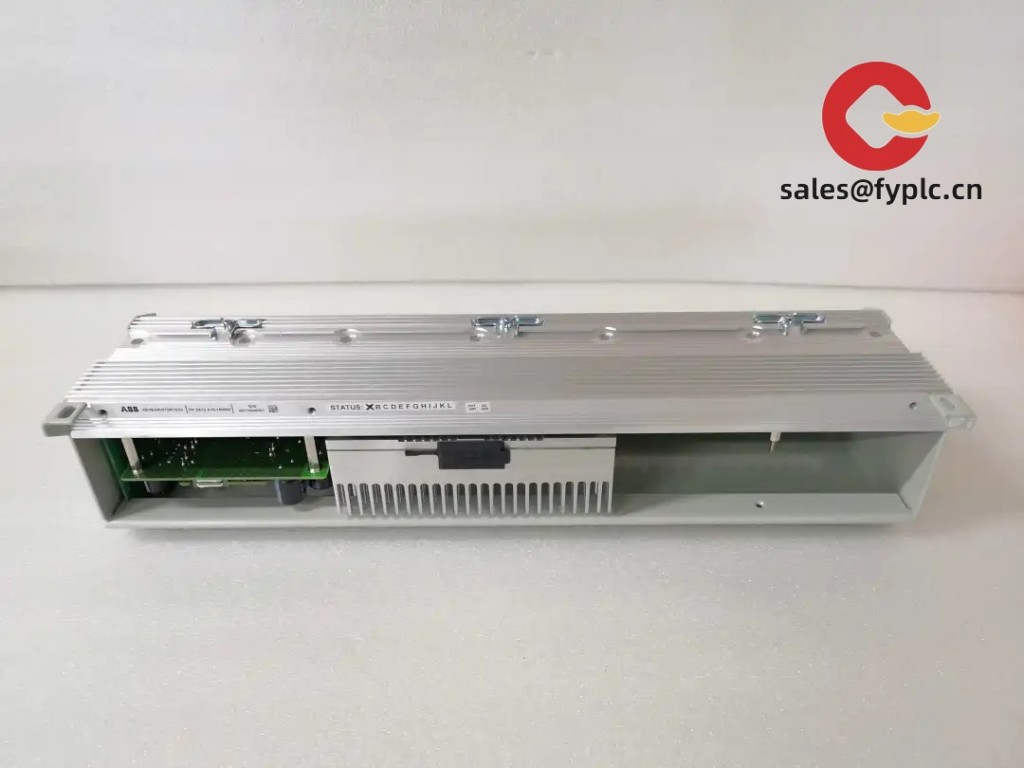

ABB PPD539A102 (3BHE039770R0102) Control Board – Reliable spare for ABB industrial drive systems

The ABB PPD539A102, part number 3BHE039770R0102, is a factory-grade control/logic PCB used inside ABB drive and control platforms. From my experience, it’s typically deployed as a plug-in board on the drive’s internal backplane, handling core control and signal processing so the line keeps running without drama. If you’re maintaining installed ABB assets and want a straight, drop-in replacement that keeps parameters and wiring unchanged, this is exactly the sort of board maintenance teams like to keep on the shelf.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: Typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

One thing I appreciate is how straightforward the replacement process can be: confirm the exact code on your removed board (PPD539A102 / 3BHE039770R0102), share the drive type label if possible, and we’ll match revision compatibility before shipping.

Key Features

- Genuine ABB spare – Matched by code PPD539A102 (3BHE039770R0102) to minimize configuration changes.

- Backplane-powered design – Draws low-power DC from the host drive; no separate PSU typically required.

- Industrial-grade PCB – Robust layout for cabinet environments; seems to be designed with EMI/ESD resilience in mind.

- Fast swap-out – Plug-and-secure installation helps reduce downtime during maintenance windows.

- Revision control – A102 hardware revision improves interchangeability within the same drive family.

- Service-friendly cues – You might notice on-board test points and status indicators that aid troubleshooting on-site.

Technical Specifications

| Brand / Model | ABB PPD539A102 – 3BHE039770R0102 |

| HS Code | 850490 (Parts for static converters / drives) |

| Power Requirements | Supplied via host backplane; typically 24 VDC low-power draw from the drive/control unit |

| Operating Temperature | Typically 0 to +55 °C when installed in a ventilated control cabinet |

| Signal I/O Types | Backplane control signals; board-level digital/analog interfaces as defined by the host drive platform |

| Communication Interfaces | Proprietary ABB backplane interface; user access typically via the drive HMI/ports rather than the board itself |

| Installation Method | Plug-in PCB within the drive/control rack; secured with standoffs/screws; ESD-safe handling required |

| Dimensions & Weight | Compact board-level module; approx. 0.25 kg (varies slightly by revision) |

Application Fields

This board is used inside ABB industrial drive systems found across continuous and batch operations. Typical environments include:

- Metals: rolling lines, coilers, leveling lines where uptime is critical

- Pulp & Paper: winders, calendars, sectional drives with coordinated control

- Mining & Cement: conveyors, crushers, feeders exposed to dust and vibration

- Chemicals & Plastics: extruders, mixers with tight speed/torque control

- Marine & Cranes: hoists and winches that demand stable low-speed performance

A maintenance lead told us they swapped a failed logic card with this code and were running again in under an hour, largely because the wiring and parameter set stayed unchanged. That’s the real-world value for most teams under production pressure.

Advantages & Value

- Reliability – Genuine ABB hardware with controlled revisions; helps stabilize installed bases.

- Compatibility – Matches by exact code (PPD539A102 / 3BHE039770R0102) to reduce firmware or parameter friction.

- Cost Savings – A targeted board replacement is often far more economical than a full drive changeout.

- Downtime Reduction – Quick installation and minimal re-commissioning in most cases.

- Technical Support – Pre-shipment compatibility checks and guidance for safe handling and fit-up.

Installation & Maintenance

- Environment – Install within a clean, ventilated control cabinet (IEC-style or equivalent). Avoid condensation and conductive dust.

- Power-down & LOTO – Fully isolate the drive, wait for DC bus discharge, and follow lockout/tagout procedures.

- ESD Protection – Use a grounded wrist strap and antistatic mat; handle by edges only.

- Mechanical Fit – Align to the backplane connector; secure with the original standoffs/screws to avoid vibration issues.

- Wiring & Orientation – Verify connector orientation and seating; do not force headers. Recheck any ribbon or fiber jumpers if present.

- Commissioning – Restore backed-up parameters if required; verify interlocks and run a controlled start.

- Routine Care – Periodically check cabinet filters, clean light dust with dry air (low pressure), and keep firmware at the recommended revision for the host drive.

- Spare Strategy – In many cases, keeping one validated spare per line or per drive family significantly reduces MTTR.

Quality & Certifications

- Manufactured within ISO 9001 quality systems

- CE-compliant as part of the complete drive system

- RoHS-compliant materials where applicable for the product family

- UL/CSA recognition typically applies at the drive assembly level

- Manufacturer’s warranty: 12 months (365 days)

Related and Supporting Items

If you’re planning a preventive maintenance stop, it often makes sense to review complementary items: backplane ribbon cables, mounting hardware, and cabinet filters. Share the drive nameplate and we’ll confirm whether this PPD539A102 board pairs with your specific control unit revision—there are subtle differences across ABB platforms, and checking first usually saves time on site.

Quick Quote Checklist

- Exact code on the removed board: PPD539A102 / 3BHE039770R0102

- Drive model/type and serial number

- Any error codes or fault logs observed

- Required delivery window and shipping method (FedEx / UPS / DHL)

Reviews

There are no reviews yet.