Description

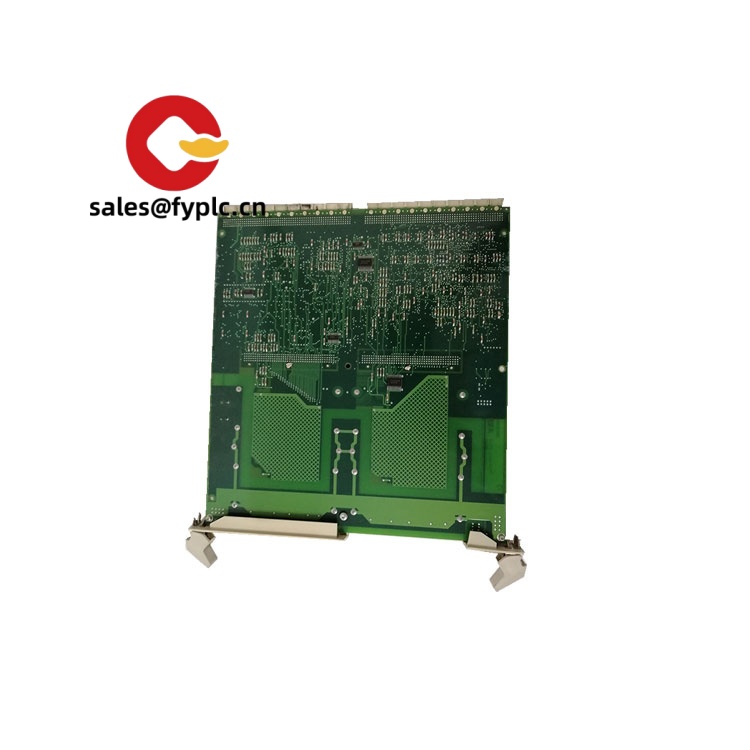

ABB SC510 (3BSE003832R1) – Communication Interface Module for ABB control networks and legacy migration

From my experience, the ABB SC510 3BSE003832R1 is typically used as a robust communication interface within ABB control architectures, especially where you need reliable connectivity to legacy networks alongside modern ABB systems (Advant, Symphony/800xA, or S800 I/O environments). It’s the kind of module you pick when plant uptime matters and you still have critical nodes on serial or ABB-heritage fieldbuses that must keep talking without drama.

Our Order Process & Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance; full payment before delivery

- Express options: FedEx, UPS, DHL

- Condition: Professionally inspected and tested prior to ship-out

Key Features

- Designed for ABB ecosystems – Integrates neatly in ABB control setups, commonly seen bridging legacy segments within 800xA/Advant-based projects.

- Industrial serial/fieldbus connectivity – Provides serial-style fieldbus communication for brownfield connections where replacement isn’t practical yet.

- Stable under electrical noise – EMC-hardened design suited for substations, chemical plants, and heavy manufacturing lines.

- S800 mounting style – Installs on ABB module termination units (TU8xx series) for quick panel build and service access.

- Diagnostics you can see – Front-face status LEDs help maintenance teams quickly identify bus or power issues during shifts.

- Lifecycle-friendly – Useful for phased migrations; you can keep a legacy segment alive while moving the rest of the plant to a newer platform.

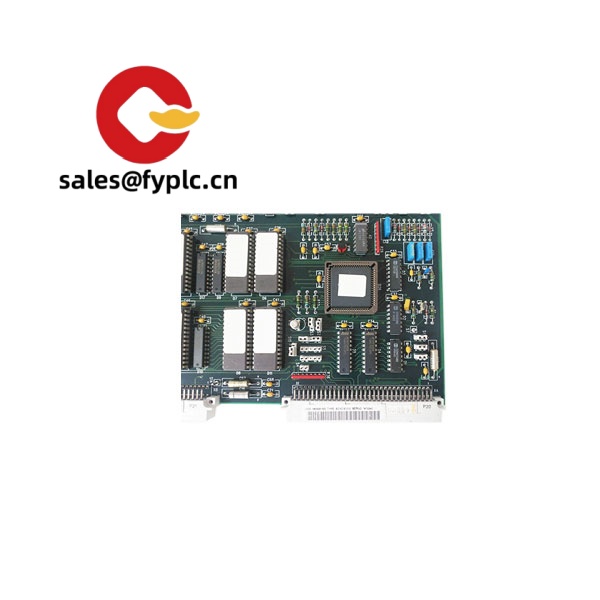

Technical Specifications

| Brand / Model | ABB SC510 – 3BSE003832R1 |

| HS Code | 8537.10 (Boards/panels for electric control, ≤1000 V) |

| Power Requirements | 24 V DC supplied via ABB backplane/MTU (typical S800 power distribution) |

| Dimensions & Weight | Single-width S800 module format; approx. 45 mm (W) × 119 mm (H) × 121 mm (D), ~0.2 kg |

| Operating Temperature | 0 to +55 °C (typical for cabinet-mounted ABB modules) |

| Signal I/O Types | Serial/fieldbus communication interface for ABB and legacy network segments |

| Communication Interfaces | Industrial serial fieldbus (model-/project-dependent; commonly used in legacy ABB integrations) |

| Installation Method | Mounts on ABB S800 MTUs (e.g., TU810/TU814/TU830 series) on DIN rail within a control cabinet |

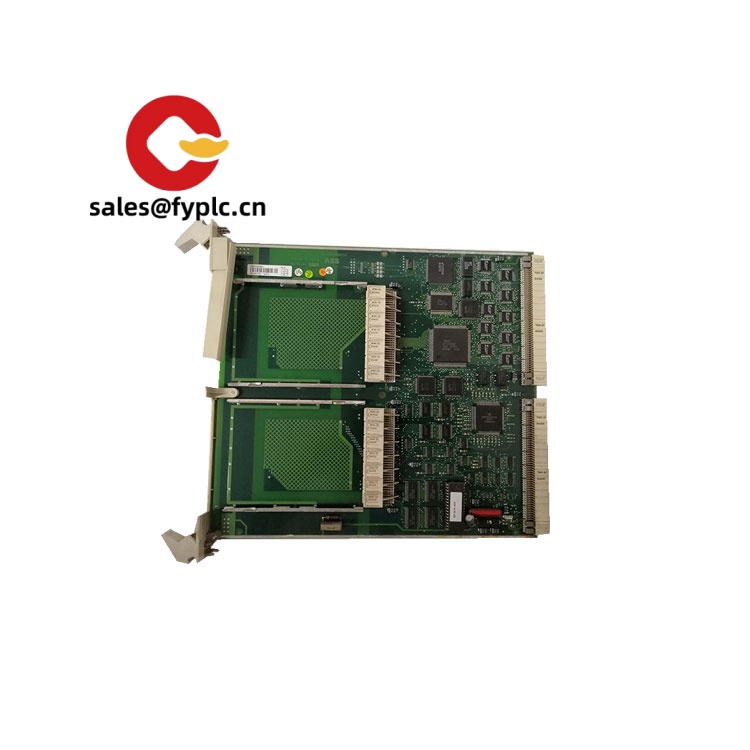

Application Fields

You might notice that the SC510 shows up most in brownfield projects. Plants that have ABB legacy nodes and still need deterministic, low-maintenance comms tend to favor it. Typical places we see it:

- Power generation and water treatment where long-lived legacy loops stay in service

- Oil & gas and petrochemical units needing stable serial bus segments inside hazardous-area architectures

- Metals, pulp & paper, cement lines mid-migration to 800xA with staged cutovers

- Utilities substations with EMC-heavy environments and strict uptime targets

Advantages & Value

- Compatibility where it counts – Keeps existing ABB and serial-bus assets communicating, avoiding a risky “big-bang” replacement.

- Lower total project risk – In many cases you reduce commissioning hours because wiring and addressing can stay put.

- Serviceability – Clear front-panel diagnostics and the standard S800 form factor help technicians swap and verify fast.

- Longevity of supply – Helps extend the useful life of legacy cells while planning a phased modernization.

Installation & Maintenance

- Cabinet & mounting – Install on an ABB TU8xx MTU, DIN-rail mounted in a ventilated cabinet (IEC/EN industrial control panel standards). Leave clearance for convection and cable bend radius.

- Power & grounding – 24 VDC via the backplane; ensure stable, low-ripple supply. Bond cabinet PE properly and maintain shield terminations for serial/fieldbus cables at a single-point ground to limit noise.

- Wiring – Use twisted pair, shielded cable for RS‑485 style links. Keep separation from power cables; route shields to the designated ground clamp.

- Safety – ESD protection during handling; de-energize the segment if your site standard requires it. Follow ABB replacement procedures if performing online swaps.

- Routine care – Quarterly dust inspection, connector re-seat if needed, and check diagnostics. Firmware/config backups should be part of your change management.

Quality & Certifications

- Certifications – CE; RoHS compliance; UL/CSA for many production lots (cert scope can vary by manufacturing date).

- Manufacturer’s practice – Industrial EMC and safety standards aligned with ABB’s S800/Advant families.

- Warranty – 365 days (unit tested before dispatch).

Recommended Supporting Components

To make engineering and maintenance smoother, these companions usually pair well with SC510 in the field:

- ABB TU810/TU814/TU830 MTUs – Module termination units providing the backplane power and signal interface for S800-style modules.

- DIN-rail power supplies (24 VDC, industrial) – With low ripple and sufficient hold-up time for brownouts.

- Shielded twisted-pair cabling – RS‑485 grade cable with proper drain wire and ferrules to maintain EMC performance.

Field feedback from a retrofit team lead: “We used the SC510 to keep a legacy serial segment stable while migrating the main DCS. Diagnostics were straightforward and we didn’t need to rework the whole cabinet. That saved us a weekend of downtime, probably more.”

Reviews

There are no reviews yet.