Description

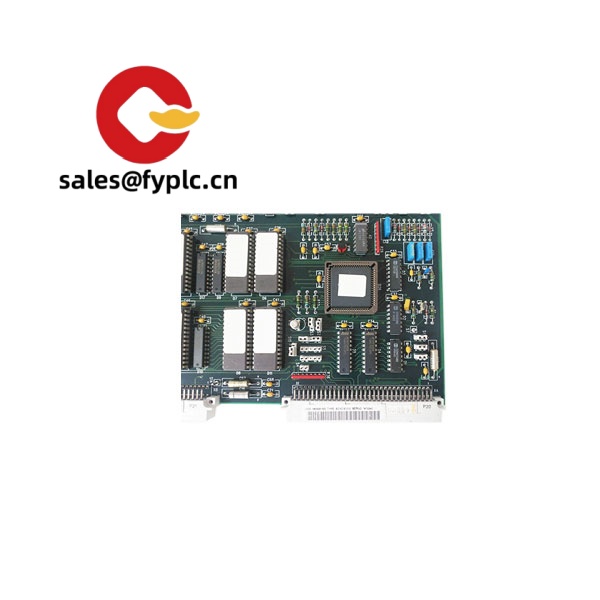

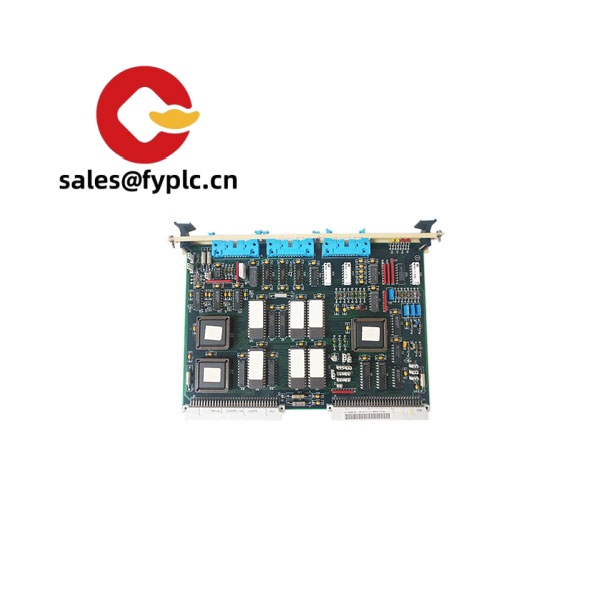

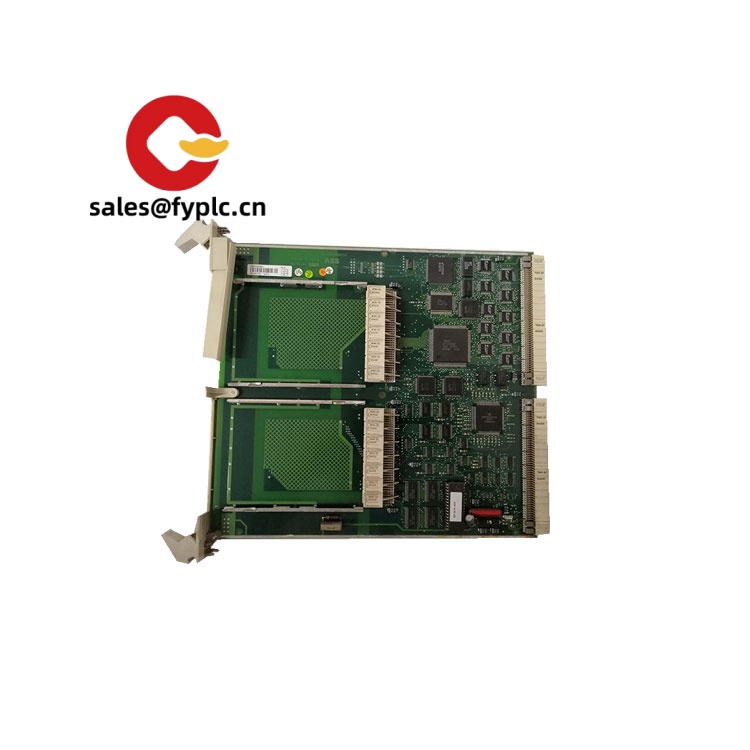

ABB SCYC51010-58052515G – Industrial Control Cable Assembly for Servo/Encoder/IO Integration

The SCYC51010-58052515G seems to be a robust, factory-terminated cable assembly designed for industrial control environments—typically used to connect servo drives, encoder feedback, or sensor/IO blocks to control cabinets. From my experience, models in this format are specified for stable signal transmission, proper shielding, and dependable performance in cabinets or light-to-medium motion applications (such as routing through drag chains with the correct jacket choice). If you’re replacing a legacy harness or standardizing spares, this model is a straightforward, cost-effective option.

One thing I appreciate is how these assemblies reduce wiring variability on the shop floor—pinouts are fixed at production, strain relief is tidy, and the shielding is consistent. You might notice that troubleshooting becomes quicker as well: fewer field-made joints usually means fewer intermittent faults.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Pre-shipment checks: Visual inspection and continuity test on cable assemblies

Key Features

- Factory-terminated, consistent quality – Reduces field wiring time and eliminates pinout guesswork.

- Shielded construction – Typically minimizes EMI in servo and encoder lines, improving signal integrity.

- Industrial-grade jacket – Suited for cabinet routing and, in many cases, light drag-chain applications when specified.

- Stable connectors – Tight, repeatable mating for maintenance swaps and scheduled overhauls.

- Service-friendly – Clear labeling and strain reliefs make installs and replacements quicker.

Technical Specifications

Note: Exact pinout, connector type, and jacket grade are confirmed against your application before shipment. That’s the safest way to match existing harnesses.

Application Fields

- Servo/drive feedback loops on CNC and packaging lines

- Sensor and IO distribution in assembly cells and test stations

- Material handling systems—encoders on rollers, position switches, and safety circuits

- Robotics harnessing for auxiliary axes or end-of-arm IO (where flex rating is appropriate)

A packaging OEM told us they’ve run this style of SCYC harness for 18 months in a moderate-duty drag chain without signal dropouts—shielding and strain relief seem to be doing their job.

Advantages & Value

- Reliability – Factory-terminated and tested; fewer on-site wiring variables.

- Compatibility – Pinouts validated to your device or drawing, reducing rework risk.

- Cost Savings – Less installation time and fewer service call-backs in most cases.

- Technical Support – We review bend radius, shielding, and jacket selection so the cable fits the environment, not just the connector.

Installation & Maintenance

- Environment – Route inside standard control cabinets or protected cable trays; avoid tight corners and sharp edges.

- Bend radius – Maintain at least 7.5× to 10× cable OD (stricter for continuous-flex applications).

- Shielding – Bond shields to cabinet ground at one end unless your EMC plan specifies otherwise.

- Strain relief – Use cable glands and clamps near terminations; prevent connector stress during machine motion.

- Routine checks – Quarterly visual inspection for jacket abrasion; annual continuity/insulation test where critical.

- Documentation – Keep the pinout and wiring diagram with the machine file to speed future replacements.

Quality & Certifications

- RoHS and REACH compliant materials (typical for SCYC control-grade cable)

- UL AWM cable styles commonly available on request

- CE marking applicable to EMC-conformant assemblies in cabinet systems

- Manufacturer’s warranty: 12 months from shipment

Helpful Add-ons (often ordered together)

- M12 panel receptacles or bulkhead adapters

- Cable glands (M16/M20) and strain-relief clamps for DIN rail

- Shield bonding straps and EMC grounding hardware

- Numbered ferrules and wire markers for panel documentation

Reviews

There are no reviews yet.