Description

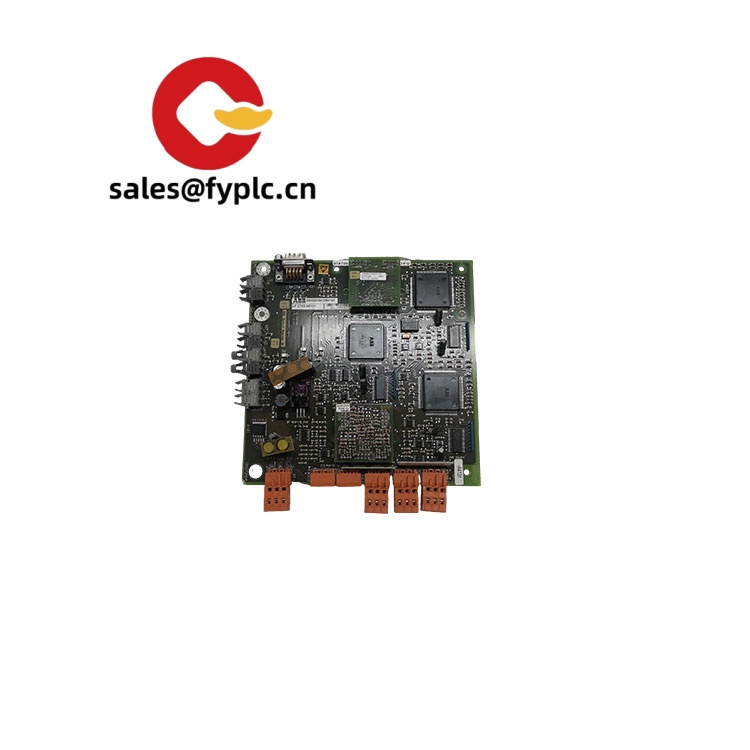

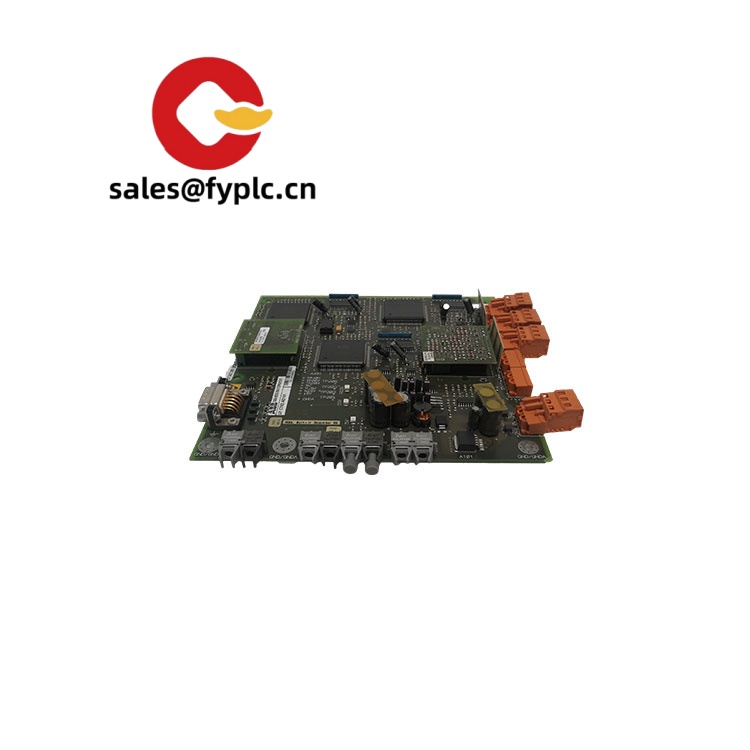

ABB UFC762AE101 (3BHE006412R0101) – CPU module for AC 800F / Freelance DCS control tasks

The ABB UFC762AE101, part number 3BHE006412R0101, is a controller CPU module used in AC 800F (Freelance DCS) systems. From my experience, it’s the piece that carries the control strategy, fieldbus communications, and diagnostic services for a lot of brownfield upgrades where you want a stable, proven platform rather than a risky redesign. You might notice that projects pick this module when they need straightforward PROFIBUS-based I/O, tight cycle times, and long-term maintainability.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: Typically 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Designed for AC 800F / Freelance DCS – Runs control logic, task scheduling, and diagnostics for ABB Freelance-based architectures.

- Fieldbus-centric I/O – Connects to remote I/O via industrial buses (typically PROFIBUS DP/PA; Modbus commonly available), reducing local wiring complexity.

- Industrial Ethernet for engineering – 10/100 Mbps Ethernet for configuration, service, and HMI connectivity in many cases.

- Deterministic control cycles – Stable scan times suited for continuous process control and utility systems.

- Redundancy-ready architectures – Often used in redundant controller pairs to raise availability (project- and firmware-dependent).

- Compact DIN-rail mount – Fits cleanly in standard control cabinets with 24 VDC power.

- Lifecycle-friendly – Common in maintenance programs replacing older UFC76x units with minimal software rework when versions align.

Technical Specifications

| Brand / Model | ABB UFC762AE101 (Part No. 3BHE006412R0101) |

| HS Code | 8537.10 (Programmable controllers) |

| Power Requirements | 24 VDC nominal (typically 18–30 VDC); power consumption ≈ up to 10 W in most cases |

| Dimensions & Weight | Approx. 185 × 120 × 65 mm (H×W×D); ~0.8 kg (typical module form factor) |

| Operating Temperature | 0 to +55 °C; 5–95% RH non‑condensing (typical for this series) |

| Signal I/O Types | No local analog/digital I/O on the CPU; remote I/O via fieldbus (AI, AO, DI, DO via connected I/O modules) |

| Communication Interfaces | Ethernet 10/100 Mbps (engineering/HMI); PROFIBUS DP (master); serial interface such as RS‑232/485 is common; options depend on project firmware and accessories |

| Installation Method | DIN‑rail mounting (EN 60715) in a ventilated control cabinet; 24 VDC power distribution; shielded cabling for fieldbuses |

Application Fields

Common in continuous and hybrid process environments: oil & gas utilities, power & steam balance-of-plant, chemicals, water & wastewater, pulp & paper, metals, and cement. One thing I appreciate is how well it slots into existing PROFIBUS-based I/O architectures—S700/S800-style remote I/O is typically straightforward—so plant downtime can be kept short during replacements or expansions.

Advantages & Value

- Reliability – Stable control behavior and long service history in Freelance DCS environments.

- Compatibility – Works with established ABB engineering tools and common fieldbus I/O, which typically saves re-engineering time.

- Lifecycle cost – Reuse of cabinets, wiring, and remote I/O reduces project risk and total installed cost.

- Supportability – Clear migration path within the AC 800F family; firmware and spare strategies are usually well documented.

A maintenance lead recently shared that swapping a legacy UFC76x unit for a UFC762AE101 was smooth after aligning firmware and fieldbus settings—the DCS accepted the controller with only minor downtime. That’s typically how these upgrades go when planning is tight.

Installation & Maintenance

- Cabinet & mounting – Install on DIN rail in a clean, ventilated cabinet. Keep 50 mm clearance above/below where possible for airflow.

- Power & grounding – 24 VDC supply with proper sizing; common reference ground; segregate power, Ethernet, and fieldbus cabling.

- Fieldbus wiring – Use shielded twisted pair for PROFIBUS/RS‑485; maintain segment lengths, termination, and spur rules. Label nodes for easy service.

- Environmental – Operate within 0…55 °C and non‑condensing humidity. Avoid dust ingress; consider filtered cabinet fans if necessary.

- Routine maintenance – Periodic backups of controller configuration, check event logs, verify firmware alignment with peer/standby units, inspect connectors and terminations, replace aging SD/CF media if used.

- Safety – De-energize the panel before insertion/removal, observe ESD precautions, and follow ABB manuals for redundancy switchover procedures.

Quality & Certifications

- CE compliant; RoHS alignment typical for this product family

- UL/cUL listing is commonly available on ABB controller hardware (project-specific verification recommended)

- Manufactured under ISO 9001 quality systems

- Manufacturer’s hardware warranty applies; we provide 365-day coverage on supply

Related/Supporting Components (often paired)

- Remote I/O over PROFIBUS DP/PA (e.g., ABB S700/S800 families depending on project)

- Managed industrial Ethernet switches for engineering/HMI networks

- 24 VDC industrial power supplies with redundancy modules

- Shielded PROFIBUS cabling, connectors, terminators, and diagnostic testers

If you’re replacing an older controller, I typically recommend confirming firmware levels, bus addresses, and memory card handling before the changeover—those small checks tend to prevent last‑minute surprises.

Reviews

There are no reviews yet.