Description

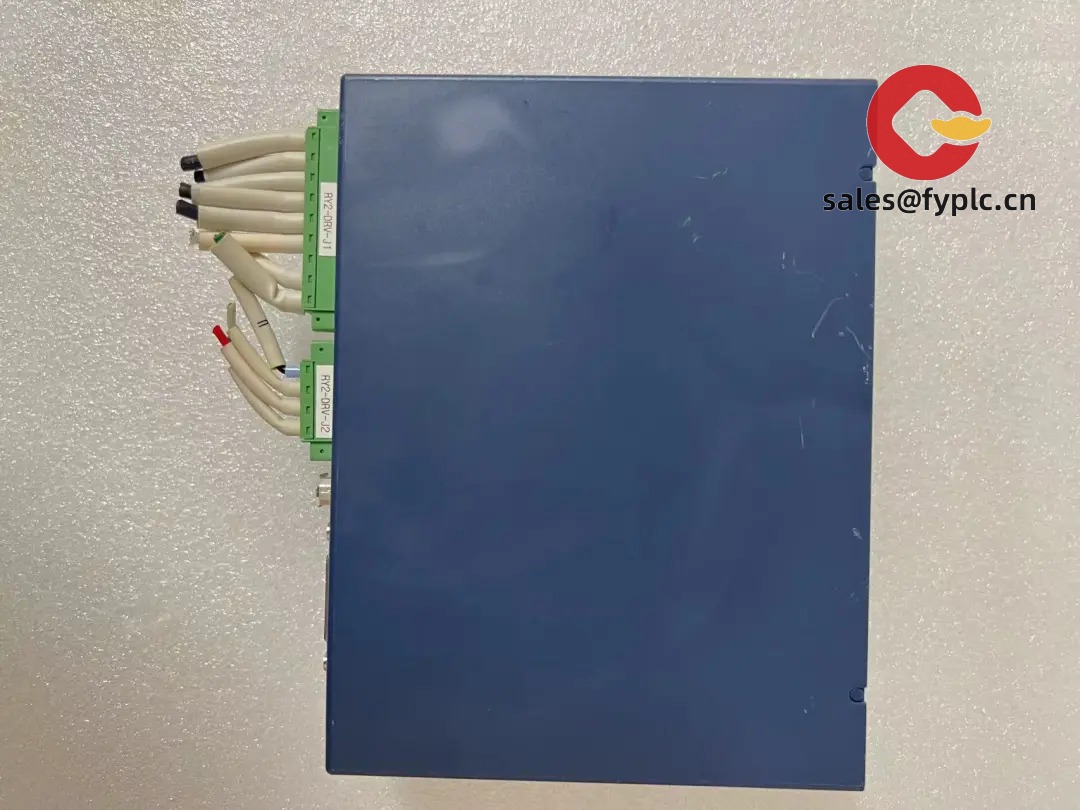

Danaher Motion S20660-SRS – S200 Series AC Servo Drive for Precise, Responsive Motion Control

The Danaher Motion S20660-SRS is part of the S200 digital servo drive family, widely used for mid-power axes where stable torque, clean velocity control, and quick positioning matter. From my experience, it’s a dependable choice for upgrading legacy Danaher Motion/Kollmorgen systems or keeping an existing line running with minimal changes to wiring and motor selection. You might notice that the -SRS suffix typically indicates a resolver-feedback variant, which is favored in tougher environments where resolvers’ robustness shines.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Resolver feedback (-SRS) – Typically supports resolver motor feedback for high durability in vibration and temperature variations.

- Multi‑mode control – Torque, velocity, and position modes; suitable for analog ±10 V, pulse/step-direction, or digital command structures depending on configuration.

- Stable tuning and quick setup – Auto-tuning and RS‑232 based commissioning tools help get a new axis productive faster.

- Universal AC input – Designed for 200–240 VAC operation; many S200 frames also work on 120 VAC for lower power motors.

- Integrated protections – Over-voltage, over-current, motor short, over-temp, and safe shutdown routines help protect your machine.

- Compact cabinet footprint – Book-size drive typically fits dense multi-axis panels without reworking the enclosure.

- Proven compatibility – Pairs well with Kollmorgen/Danaher Motion servomotors (e.g., AKM series), reducing integration risk.

Technical Specifications

| Brand / Model | Danaher Motion S20660-SRS (S200 Series AC Servo Drive) |

| HS Code | 8504.40 (Static converters / AC servo drive) |

| Power Requirements | 200–240 VAC, 50/60 Hz (single‑phase typical; 120 VAC operation may be supported on lower power motors) |

| Operating Temperature | 0 to +40 °C typical (allow derating above standard range; ensure cabinet ventilation) |

| Signal I/O Types | Analog ±10 V command, step/direction or pulse train, discrete digital I/O (enable, inhibit, fault, home/limits) – varies by configuration |

| Communication Interfaces | RS‑232 for commissioning; optional fieldbus variants exist within the S200 family |

| Feedback Support | Resolver feedback (as indicated by -SRS); other S200 variants may support incremental encoder |

| Installation Method | Panel/cabinet mounting, vertical orientation; shielded motor/feedback cabling and proper earth bonding recommended |

Application Fields

This model is commonly used in multi-axis packaging lines, labeling and print registration, electronics assembly, light machine tools, feeders, pick‑and‑place gantries, and indexing systems. One thing I appreciate is how the S200 handles cyclic profile moves—on cartoners and case packers it tends to produce smooth motion with less tweaking than some generic drives. A plant maintenance lead recently told us it “dropped in seamlessly as a replacement for an older Danaher drive and brought the axis back up within a morning shift.”

Advantages & Value

- Lifecycle continuity – Ideal for replacements in established Danaher Motion/Kollmorgen bases, minimizing re-engineering.

- Reliable resolver feedback – In many cases more tolerant to electrical noise and high temperatures than incremental encoders.

- Commissioning speed – RS‑232 tools and proven auto‑tuning shorten startup and reduce trial‑and‑error.

- Cost control – Keeps your existing motors and mechanics in service; reduces retrofit scope and downtime.

- Support – Access to parameter backups, wiring guidance, and replacement stock to keep lines running.

Installation & Maintenance

- Cabinet environment – Mount vertically in a clean, dry enclosure; maintain clearance for convection; provide forced ventilation if ambient exceeds 40 °C.

- Wiring practices – Use shielded motor and feedback cables with 360° shield termination; separate power and signal runs; bond PE/ground with low impedance.

- EMC & safety – Fit line filtering where required; confirm mains disconnect; wait for DC bus to discharge before servicing (bus LEDs off).

- Routine checks – Inspect connectors for looseness, clean heatsink surfaces, verify fan/airflow if used, and back up parameter sets after changes.

- Firmware & tuning – Keep firmware at approved levels; re‑validate tuning after mechanical changes or payload updates.

Quality & Certifications

- Conforms to CE marking and typically UL/cUL listings for industrial control equipment

- RoHS-compliant construction in most production batches

- Warranty: 365 days from delivery

Reviews

There are no reviews yet.