Description

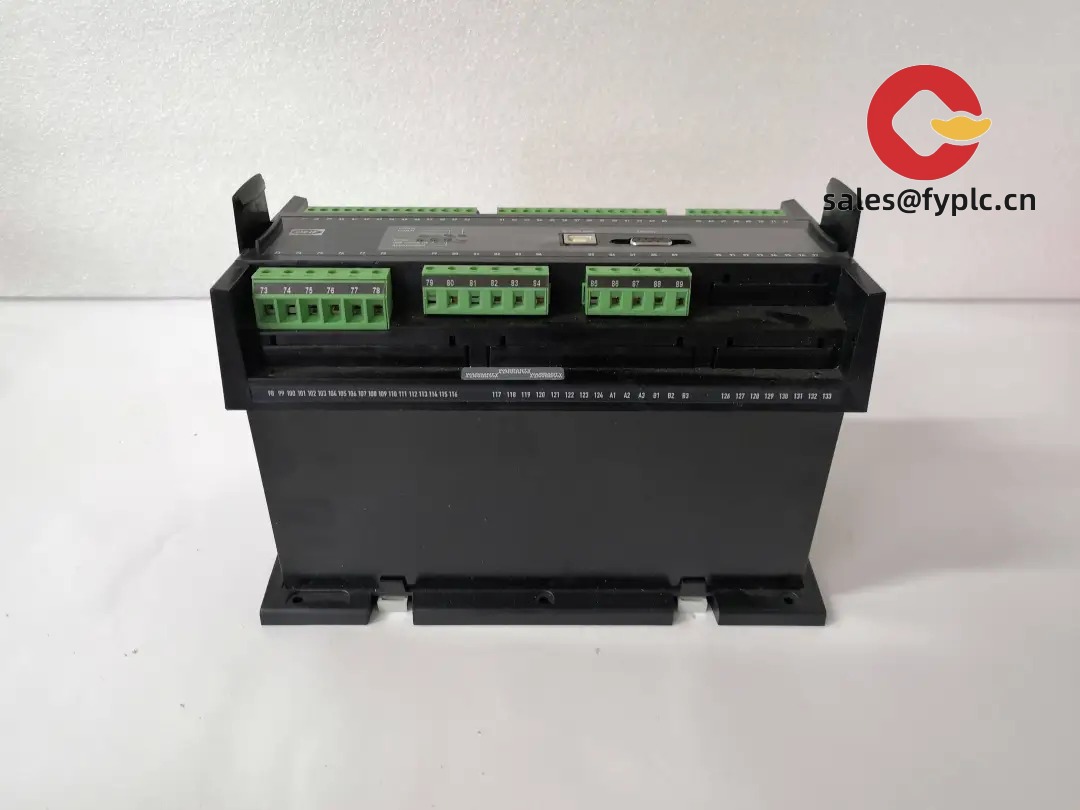

DEIF PPU-3 – Generator Paralleling & Protection Unit for Reliable Switchboard Control

DEIF’s PPU-3 is a compact protection and synchronising controller designed for generator sets and mains-parallel applications. From my experience, it’s a solid choice when you need dependable automatic synchronising, breaker control, and a well-rounded protection suite without building a big relay panel from scratch. You might notice that it reduces wiring complexity, makes commissioning predictable, and typically plays nicely with existing CT/VT measurement and standard breaker coils.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Automatic synchronising & sync-check: Handles live bus and dead-bus conditions with precise breaker close commands.

- Integrated generator protection: Typically includes over/under voltage and frequency, reverse power, and overcurrent functions for safe operation.

- 3‑phase measurement via CT/VT: Direct connection to current transformers and potential transformers for accurate metering and protection.

- Flexible I/O and relay outputs: Digital inputs for status and permissives; form‑C relay outputs for breaker control and alarms.

- Modbus connectivity: RS‑485 (Modbus RTU) for SCADA/BMS integration—handy for remote supervision and trending.

- Panel‑mounted HMI: Clear front panel with indicators/keys, making local setup and status checks straightforward.

- Rugged 24 VDC supply: Suited for switchboard environments with stable operation across typical control voltages.

Technical Specifications

| Brand / Model | DEIF PPU-3 |

| HS Code | 8537.10 (Boards, panels, consoles for electric control, ≤1000 V) |

| Power Requirements | 24 VDC nominal (typically 8–36 VDC input), power < 15 W |

| Dimensions & Weight | Front 144 × 144 mm; panel cut‑out approx. 138 × 138 mm; depth ~200 mm; weight ~1.5 kg (typ.) |

| Operating Temperature | -20 to +55 °C (typical for switchboard installation) |

| Signal Input/Output Types | 3‑phase AC voltage (VT) & current (CT) inputs; binary inputs; form‑C relay outputs; optional analog 4–20 mA |

| Communication Interfaces | RS‑485 (Modbus RTU); optional CAN or service port depending on variant |

| Installation Method | Panel/flush mount in switchboard; rear terminal blocks; CT/VT wiring per polarity and burden specs |

Application Fields

The PPU-3 fits well in generator switchboards where safe paralleling and robust protection are non‑negotiable. Typical scenarios include:

- Diesel and gas genset paralleling (island mode and mains parallel)

- Prime power plants and IPP rental fleets needing quick setup

- Hospitals, data centers, and airports with stringent switching sequences

- CHP and microgrid projects with utility tie-in

- Marine and offshore switchboards (approvals vary by variant)

A utilities client told us they swapped it in for an aging relay set and had commissioning wrapped up in under a day—no surprises on CT ratios or sync logic, which tends to be where time goes.

Advantages & Value

- Reliability you can measure: Integrated protection and sync logic reduce interwiring errors versus discrete relays.

- Compatibility: Works with standard CTs/VTs and common breaker coils, so retrofit risk is lower in many cases.

- Cost‑effective panels: Fewer devices and smaller door cut‑outs mean leaner switchboard layouts.

- Data visibility: Modbus integration gives your SCADA or BMS direct access to measurements and alarms.

- Support & lifecycle: Stable firmware and a clear parameter structure make future changes less painful.

Installation & Maintenance

From my experience, most issues come from wiring and earthing rather than the controller itself. A few practical guidelines:

- Panel standards: Install in a ventilated, dry switchboard (typ. IP54 or better for harsh sites). Keep control wiring segregated from power cabling.

- CT/VT wiring: Observe polarity (P1/P2, S1/S2) and short CT secondaries before handling. Verify burden is within the device’s limits.

- Grounding & EMC: Use a single‑point reference ground and shielded twisted pairs for comms. Route cables away from VFDs where possible.

- Breaker control: Confirm closing/ tripping coil voltage and interlock signals. Test sync‑check permissives at low risk first.

- Routine maintenance: Annual function test of protections (UV/OF/RP/OC), clean the front panel, back up parameters, and apply firmware updates when qualified.

Common supporting components: suitably rated CTs/VTs, motorised breakers (A/AR), RS‑485 gateway or converter, and governor/AVR interface leads.

Quality & Certifications

- CE marking and RoHS compliance are typically provided by the manufacturer

- Designed in line with relevant IEC protection standards (e.g., IEC 60255 family)

- UL/Marine approvals may be available on specific variants; documentation can be supplied upon request

- Manufacturer quality management commonly certified to ISO 9001

- Warranty: 365 days

If you’re consolidating older protection relays and a separate synchroscope/synchroniser, the DEIF PPU-3 seems to be a practical step up—cleaner wiring, quicker FAT, and easier remote supervision. We can help size the CT/VT ratios and set the sync window based on your breaker timing and grid code.

Reviews

There are no reviews yet.