Description

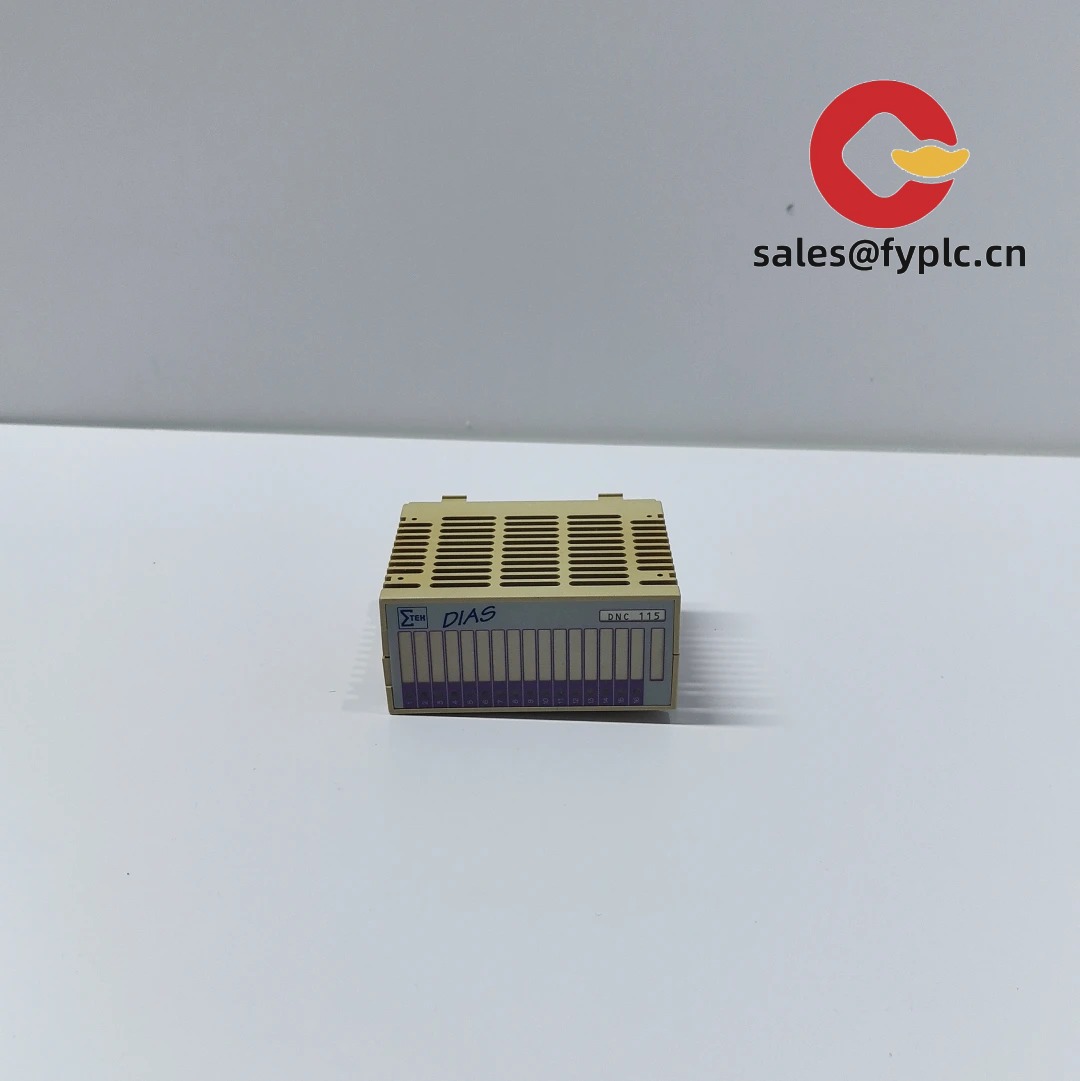

DNC115 Industrial Serial Device Server – Connect RS‑232/422/485 Equipment to Ethernet Networks

From my experience, the DNC115 is aimed at one job: getting legacy serial devices talking reliably over modern Ethernet. You might notice that it’s built for control cabinets and shop floors where PLCs, HMIs, barcode readers, meters, and drives still speak RS‑232/422/485. The DNC115 acts as a compact serial‑to‑Ethernet gateway, typically used for SCADA integration, remote diagnostics, or centralized data collection.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Multi‑protocol serial support – Typically configurable for RS‑232, RS‑422, or RS‑485, so you can connect a wide range of PLCs, drives, and sensors without additional converters.

- Ethernet enablement – Bridges serial devices to TCP/IP networks for SCADA/Historian access, remote monitoring, and data logging.

- Flexible operating modes – In many cases supports TCP Server/Client and UDP; that’s handy for both point‑to‑point links and multi‑client supervisory systems.

- DIN‑rail mounting – Compact housing designed for EN 60715 rails, which keeps panel installations neat and serviceable.

- Industrial power input – Wide‑range DC input is common on this model, simplifying power wiring from existing 24 VDC control supplies.

- Setup that doesn’t waste time – Web‑based configuration is typically available; engineers can bring a unit online in minutes.

Technical Specifications

| Brand / Model | DNC115 |

| HS Code | 851762 (Data transmission/communication apparatus) |

| Power Requirements | Typically 12–48 VDC input (reverse‑polarity protection in many cases) |

| Operating Temperature | Commonly −10 to +60 °C; wide‑temp variants may be available |

| Signal Input/Output Types | 1× Serial port (RS‑232/RS‑422/RS‑485, software‑selectable) |

| Communication Interfaces | 1× 10/100BASE‑TX Ethernet (RJ45); TCP Server/Client and UDP modes are typical |

| Installation Method | DIN‑rail (EN 60715); panel/wall mounting via optional brackets |

| Enclosure | Compact industrial housing suitable for control cabinets |

Note: Exact port count and temperature grade can vary by sub‑revision. If you’re matching a specific PLC or SCADA requirement, share your serial mode, baud rate, and cabinet power so we can validate the variant before shipping.

Application Fields

- PLC/SCADA connectivity for brownfield equipment (Modbus/RTU devices bridged to Ethernet networks)

- Machine tool retrofits where CNC controllers still use RS‑232 for program transfer and diagnostics

- Utilities and energy metering (serial meters, IEDs) aggregated to data concentrators

- Material handling systems (barcode/RFID readers, weigh scales) integrated into MES

- Process automation skids needing remote access without replacing installed serial instruments

Advantages & Value

- Low upgrade cost – Extend the useful life of serial devices instead of replacing them.

- Time‑saving commissioning – Web‑config and standard networking modes reduce on‑site setup time.

- Broad compatibility – Works with most PLC brands that support TCP/UDP redirection or virtual COM mapping.

- Serviceability – DIN‑rail form factor and DC power fit neatly into existing control cabinets.

- Risk reduction – Typically supports watchdogs and connection keep‑alive to help keep data links stable.

Installation & Maintenance

- Cabinet & environment – Install on EN 60715 DIN rails in a ventilated cabinet; avoid heat sources and high EMI areas; allow space for airflow.

- Power & wiring – Use a regulated DC supply (commonly 24 VDC). Keep serial lines shielded and grounded at one end to minimize noise on RS‑485 runs.

- Network setup – Assign static IPs for SCADA; validate TCP/UDP ports and firewall rules. For RS‑485, terminate and bias the bus as per topology.

- Safety – De‑energize circuits before wiring. Verify polarity to avoid damage. Use surge protection in harsh industrial zones.

- Maintenance – Periodically check terminal tightness, clean dust from vents, back up config files, and apply firmware updates after staging tests.

Quality & Certifications

- CE and RoHS compliance are typically available for this class of device

- Designed for industrial EMC immunity; Ethernet ESD protection is common

- Manufacturer warranty: 12 months (365 days)

Related Accessories (Optional)

- 24 VDC DIN‑rail power supply (30–60 W) to feed the DNC115 and small peripheral loads

- RS‑485 termination and surge protection kit for long serial runs

- Shielded RJ45 patch cords for noisy environments

- Panel adapter brackets if DIN‑rail space is limited

One thing I appreciate is how the DNC115 simplifies brownfield integration. A plant electrician told us they swapped a legacy modem for this unit and had their RS‑485 flow meter trending in the historian within an hour—no PLC code changes, just a port redirect. If you can share your serial mode and network scheme, we can validate compatibility and ship the right variant on the first try.

Reviews

There are no reviews yet.