Description

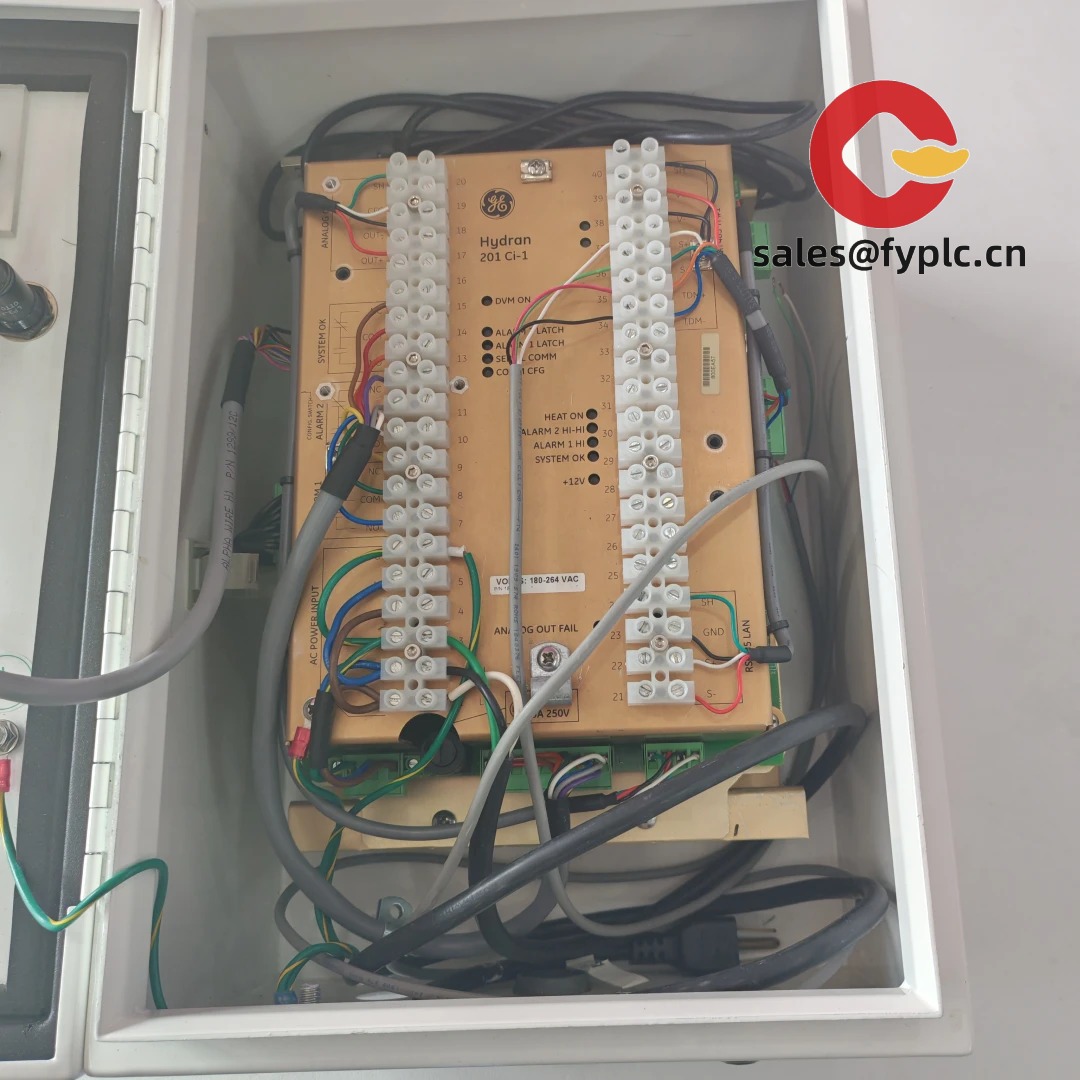

GE Grid Solutions HYDRAN H201Ci-1 – Online Composite Gas Monitor for Power Transformers

The HYDRAN H201Ci-1 is a practical, field-proven online DGA monitor designed for continuous detection of dissolved combustible gases in transformer oil. From my experience, utilities use it as an early-warning layer—especially on high-value distribution and transmission transformers—where you want something dependable watching gas trends without the cost and complexity of full multi-gas analyzers. You might notice that it also typically includes moisture-in-oil and oil temperature measurement, which makes day-to-day condition assessment faster and more consistent.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Real-time composite gas monitoring – Tracks total dissolved combustible gases (TDCG proxy) to flag fault development early, typically faster than periodic lab sampling.

- Built-in moisture and temperature sensing – Gives a clearer picture of insulation health and loading conditions without extra probes.

- Simple outputs for SCADA – 4–20 mA analog channels and dry-contact relays make integration straightforward in most cases.

- Modbus RTU over RS‑485 – A reliable, widely supported protocol for trending and alarm data retrieval.

- Valve-mounted installation – Designed to fit standard transformer oil valves with an isolation valve, minimizing outage time during installation.

- Rugged outdoor enclosure – Typically weatherproof (utility-grade), suitable for substation environments with dust, UV, and temperature swings.

- Trend and alarm management – Thresholds are usually settable so protection and maintenance teams can align alarms with fleet policies.

Technical Specifications

| Parameter | Details |

|---|---|

| Brand / Model | GE Grid Solutions – HYDRAN H201Ci-1 |

| HS Code | 9027.80 (Instruments for physical or chemical analysis – other) |

| Power Requirements | 100–240 VAC, 50/60 Hz (typical); power draw is low for continuous operation |

| Dimensions & Weight | Compact valve-mounted assembly; approx. 5–8 kg depending on valve kit and options |

| Operating Temperature | Typically −40 to +55 °C for outdoor substation environments |

| Signal Input/Output Types | Internal composite gas sensor; moisture-in-oil and oil temperature; 4–20 mA outputs; alarm/warning dry-contact relays |

| Communication Interfaces | RS‑485 (Modbus RTU) for SCADA/DCS trending and configuration |

| Installation Method | Direct transformer oil valve mounting with isolation valve; outdoor-rated enclosure |

Application Fields

This model is used on medium-to-large power and distribution transformers where continuous trending of dissolved gases has a strong ROI. It’s commonly deployed by:

- Transmission and distribution utilities watching critical substations and remote renewable interconnects

- Industrial plants (steel, mining, chemicals) seeking condition-based maintenance for main step-down transformers

- Independent power producers and data center operators needing early fault visibility to avoid forced outages

- Wind and solar collector substations where site access is limited and online monitoring saves crew time

A substation engineer told us, “We use H201 units to flag gassing trends before they hit our alarm curves; it’s not overcomplicated and it keeps our lab sampling focused.”

Advantages & Value

- Proven reliability – HYDRAN monitors have been on fleets for years; it appears that long-term drift is predictable and manageable with routine checks.

- Lower total cost – In many cases, a composite gas monitor is enough to trigger timely investigations without the price tag of full multi-gas systems.

- Easy integration – RS‑485 Modbus and analog outputs slot into existing substation RTUs or bay controllers with minimal programming.

- Compatibility – Valve-mounted design and isolation valve make installation faster on typical NPT/DIN transformer valves.

- Supportability – Straightforward firmware and parameter setup helps maintenance teams standardize across sites.

Installation & Maintenance

- Cabinet/environment – Mount on a stable transformer valve location with proper sun/rain shielding; maintain ventilation around the electronics.

- Wiring – Use shielded twisted pair for RS‑485; segregate signal and power; bond the chassis to the station earth grid.

- Oil handling – Fit with an isolation valve; purge carefully to remove air; follow site oil-handling procedures to avoid contamination.

- Safety – De-energize circuits before wiring; lock-out/tag-out; observe arc-flash boundaries and site PPE rules.

- Routine maintenance – Check trend baselines quarterly; verify analog scaling; inspect cable glands and seals annually; apply firmware updates when available.

- Calibration/validation – Compare readings with periodic lab DGA and moisture tests; adjust alarm thresholds to fleet policies if needed.

Recommended Accessories & Supporting Components

- Isolation valve kit – Enables safe removal or service without draining the transformer.

- Valve adapters – NPT/DIN adapter rings to match 1.5″ or 2″ transformer valves.

- Sun shield / rain hood – Reduces thermal swings and UV exposure in harsh yards.

- RS‑485 surge protection – Adds resilience against lightning and switching transients.

- SCADA gateway – Modbus RTU to Ethernet gateway when an IP interface is preferred.

Quality & Certifications

- Certifications – CE marked; RoHS compliant (typical for this product class)

- Enclosure – Utility-grade weatherproof construction suitable for outdoor substations

- Manufacturer’s warranty – Backed by the original manufacturer; sales warranty from us is 365 days as noted above

Reviews

There are no reviews yet.