Description

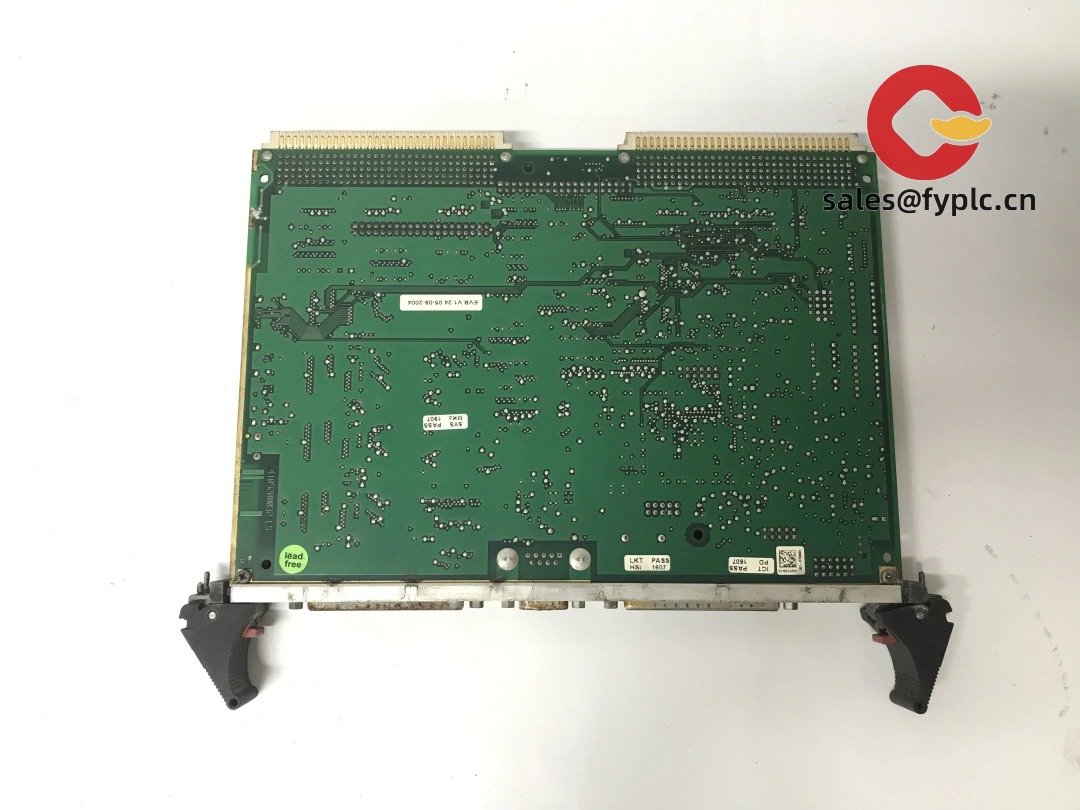

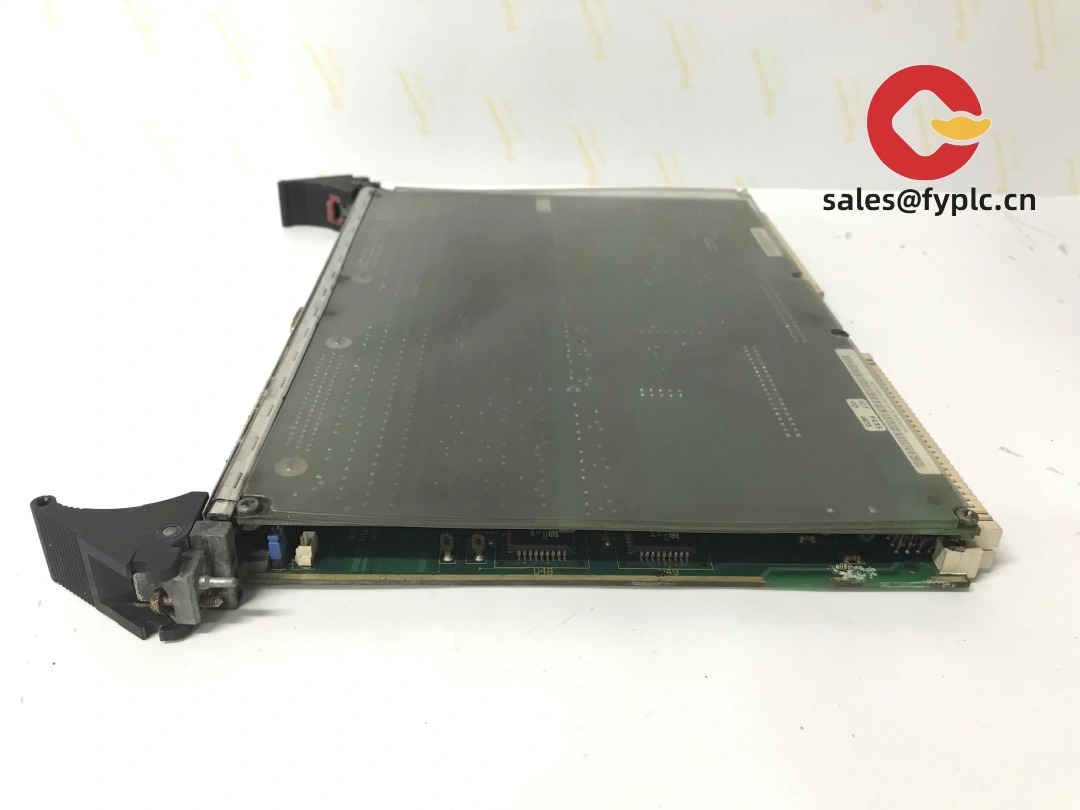

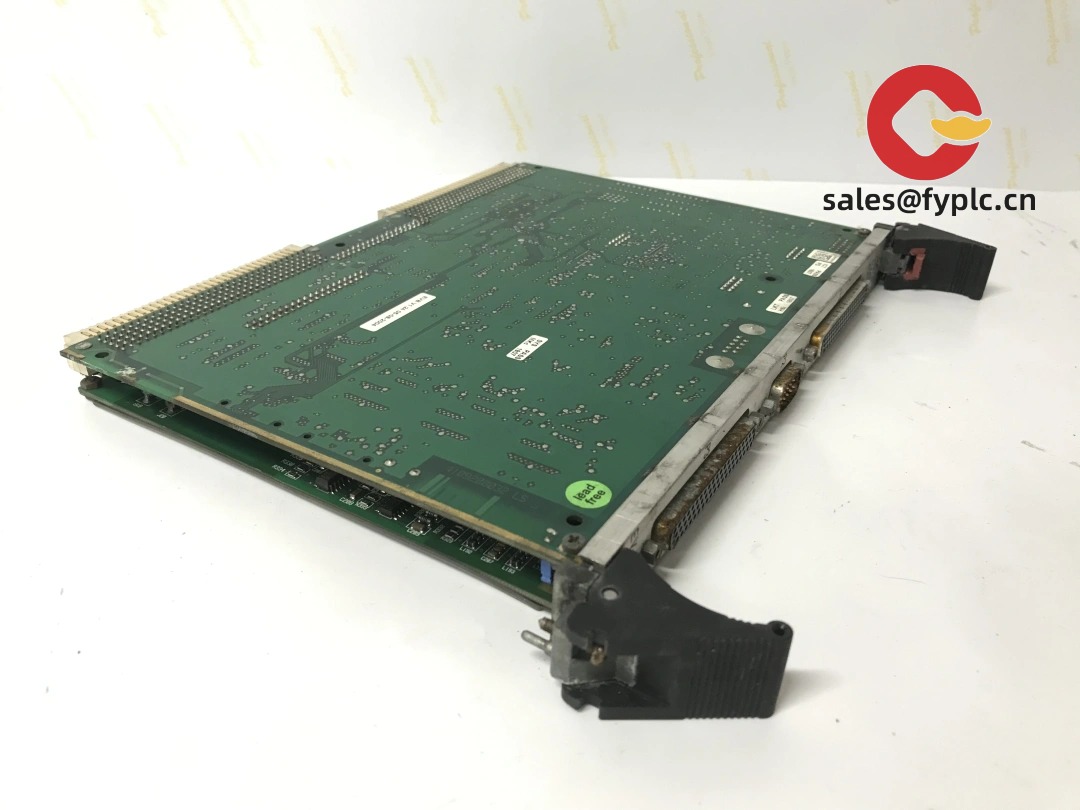

GE ECNTM13 Industrial Terminal Module – Clean Signal Breakout for Encoders and Sensors

The EVM ECNTM13 seems to be a compact terminal module designed to make encoder and sensor wiring straightforward inside a control cabinet. From my experience, modules in this format are typically used to break out multi-core cables (for example, ECN/EQN-style encoder lines or multi-signal sensor harnesses) to clearly labeled screw terminals, with a convenient point to manage shields and drain wires. You might notice that this approach cuts commissioning time and reduces troubleshooting, especially on retrofit jobs or when swapping encoders between machines.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Structured signal breakout – Brings multi-core encoder/sensor wiring to neatly arranged terminals, which typically speeds up installation and checks.

- Shield management – Provides a practical point to bond cable shields for stable signal integrity in noisy cabinets.

- Passive design – No power supply required; integrates easily into existing control panels.

- Cabinet-friendly footprint – Fits standard panel layouts and, in many cases, DIN-rail or backplate mounting.

- Serviceable connections – Screw-terminal approach helps maintenance teams isolate and test individual channels quickly.

- Encoder-ready wiring – Commonly used with incremental/absolute encoders (A/B/Z or data lines), as well as discrete sensor signals.

Technical Specifications

| Brand / Model | GE / ECNTM13 |

| HS Code | 8536.90 (Electrical apparatus for switching/protecting circuits; other – terminal/connector modules) |

| Power Requirements | None (passive breakout terminal module) |

| Operating Temperature | Typically −25°C to +60°C in enclosed control cabinets |

| Signal I/O Types | Screw terminals for multi-core encoder/sensor lines; shield/drain termination point |

| Communication Interfaces | None (signal breakout only) |

| Installation Method | Panel/backplate mounting; DIN-rail mounting in many cases |

Application Fields

Typical use cases include machine tools, packaging lines, conveying equipment, printing machinery, and general factory automation where encoder feedback and sensor bundles need orderly termination inside the cabinet. One thing I appreciate is how modules like ECNTM13 simplify retrofits—technicians can swap encoders, land wires on labeled points, and be back in production faster.

Advantages & Value

- Reliability – Cleaner wiring lowers the chance of intermittent faults from loose cores or poor shielding.

- Compatibility – Works with a wide range of encoder/sensor wiring schemes, so it fits mixed-brand environments.

- Cost Savings – Reduces build and troubleshooting time, which in many cases is the larger cost driver versus the hardware itself.

- Support – We can share wiring diagrams and typical encoder pinouts on request to speed up commissioning.

Installation & Maintenance

- Environment – Mount inside a protected control cabinet (IP-rated enclosure), with adequate ventilation and separation from high-voltage busbars to minimize noise.

- Wiring – Use ferrules where possible; follow torque recommendations for screw terminals; keep encoder pairs twisted and maintain shield continuity to the grounding point.

- Routing – Separate low-level encoder/sensor lines from VFD outputs and contactor wiring; cross at 90° if paths must intersect.

- Routine checks – Periodically re-check terminal tightness, inspect for insulation damage, and verify shield bonds, especially after thermal cycling or maintenance work.

- Documentation – Label each terminal according to your PLC/drive channel list to simplify future service calls.

Quality & Certifications

- Compliance: Typically RoHS; CE documentation available for panel components where applicable

- Manufacturing: Generally produced in ISO 9001–certified environments for consistency

- Warranty: 365 days (exchange or repair per standard terms)

Suggested Supporting Components

- Shielded encoder cables (to maintain signal integrity over longer runs)

- DIN-rail grounding clamps (for reliable shield termination)

- Pre-printed terminal markers and channel labels

If you can share the exact encoder type or a wiring diagram, I can confirm terminal assignments and provide a quick pinout map tailored to your drive/PLC. That usually shortens commissioning by a fair margin.

Reviews

There are no reviews yet.