Description

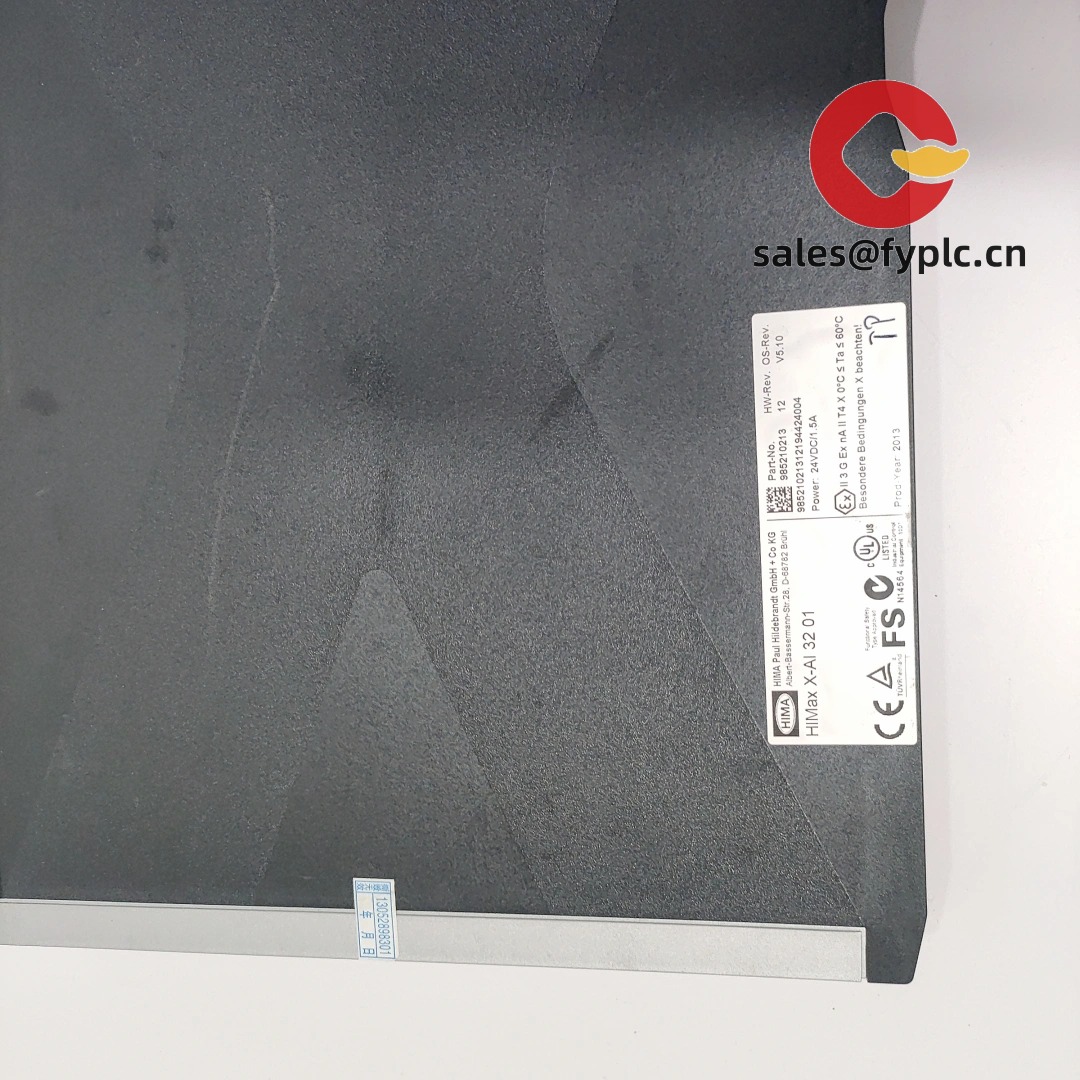

HIMI X-AI3201-985210213 – High‑Density Analog Input Module for PLC/HMI Data Acquisition

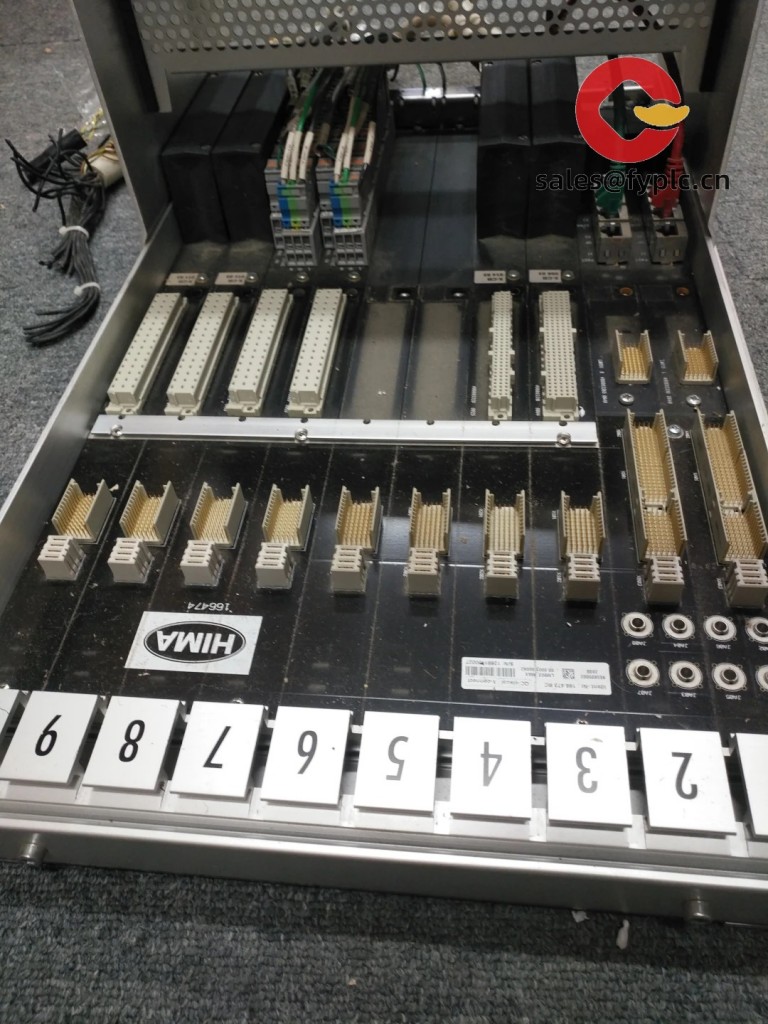

The HIMI X-AI3201-985210213 seems to be built for projects that need lots of reliable analog inputs in a compact footprint. From my experience, models with “AI3201” typically indicate a 32‑channel analog input design that works smoothly with PLCs, SCADA, and HMI-based control panels. You might notice that it prioritizes clean signal handling and easy wiring, which is exactly what maintenance teams ask for on brownfield upgrades and space-limited panels.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock, no more than 1 month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- High channel density (32 AI channels): Ideal for process skids, test benches, and multi-loop monitoring where panel space is tight.

- Voltage or current input support: Typically supports 0–10 V and 4–20 mA signals, letting you standardize on one module for most field instruments.

- Stable, low‑noise acquisition: Designed for steady readings from transmitters, load cells, and positioners in many cases.

- RS‑485 Modbus RTU integration: Simple drop‑in to existing PLC/HMI networks; addressable for multi‑node wiring.

- 24 VDC cabinet-friendly power: Common industrial supply range for quick retrofit without adding special PSUs.

- DIN‑rail mounting: Quick install and easy module replacement during maintenance windows.

- Status LEDs and labeled terminals: Faster commissioning and fault isolation on site.

Technical Specifications

| Brand / Model | HIMI X-AI3201-985210213 |

| HS Code | 8538.90 (Parts suitable for apparatus of heading 8537; reference for customs classification) |

| Power Requirements | 24 VDC nominal (typically 19–30 VDC), consumption ≈ 3–4 W |

| Dimensions & Weight | Approx. 120 × 100 × 35 mm; ~0.25 kg (module only) |

| Operating Temperature | -10 to +55 °C; 5–95% RH, non‑condensing (typical industrial environment) |

| Signal Input/Output Types | 32 analog inputs; configurable per channel for 0–10 V or 4–20 mA (common process ranges); 16‑bit resolution typical |

| Communication Interfaces | RS‑485 (Modbus RTU), up to 115.2 kbps; node address via DIP/soft setup (varies by batch) |

| Isolation & Protection | Channel-to-bus isolation (typical), input over‑range protection, reverse‑polarity power protection |

| Installation Method | 35 mm DIN‑rail (EN 60715); pluggable terminal blocks for field wiring |

Application Fields

This module fits right into multi-sensor data acquisition and slow-to-medium speed process monitoring. Typical deployments include:

- Water & wastewater SCADA – 4–20 mA pressure, level, and flow transmitters across multiple wells or chambers.

- HVAC and building utilities – reading temperature loops, valve positions, and energy meters with 0–10 V outputs.

- Food & beverage lines – batching, CIP skids, and tank farms where lots of analog loops live in one cabinet.

- Machine retrofits – adding extra AI capacity to existing PLC/HMI systems without redesigning the main rack.

- Laboratory/test stands – consolidating many analog sensors into one compact, Modbus-accessible device.

Advantages & Value

- Panel efficiency: High channel density cuts rail space and terminal clutter, which, in many cases, reduces total panel cost.

- Compatibility: Modbus RTU over RS‑485 means it plays well with most PLCs/HMIs and industrial gateways.

- Lower installed cost: One module for mixed voltage/current signals helps standardize spares and simplify wiring kits.

- Maintainability: Clear labeling and status LEDs make diagnostics faster during shutdowns.

- Service & availability: Practical lead times and a straightforward warranty reduce project risk.

Customer feedback from a recent retrofit project: “We replaced two older 16‑channel cards with one X‑AI3201. Commissioning was quicker than expected, and the Modbus mapping was predictable.”

Installation & Maintenance

- Panel environment: Mount in a ventilated enclosure (IP54 or better recommended) away from high‑EMI devices and high‑voltage cabling.

- Power & grounding: Use a clean 24 VDC supply and a solid earth reference; segregate analog, digital, and power wiring.

- Wiring practice: Shielded twisted pair for analog inputs; terminate shields at one side to avoid loops. Label every loop for maintenance.

- RS‑485 layout: Daisy‑chain topology with end‑of‑line termination (≈120 Ω) and biasing as required by the host controller.

- Routine checks: Verify zero/span against a known reference annually (or per site SOP); inspect terminals and clean dust from the vents.

- Spare strategy: Keep one spare module per cabinet cluster in critical lines to shorten recovery time.

Quality & Certifications

- CE and RoHS compliance are typically available for HIMI industrial modules.

- UL/cUL listing may vary by production lot and regional approvals; confirm per project documentation.

- Manufacturing quality aligned with ISO‑style process controls in most cases.

- Warranty: 12 months (365 days).

Common Supporting Components

- 24 VDC power supply (30–60 W): For clean and stable powering of the module and loop devices.

- RS‑485 to USB converter: Handy for bench configuration and troubleshooting with a laptop.

- DIN‑rail end clamps & wire markers: Keeps the rail tidy and improves serviceability.

- 120 Ω RS‑485 terminators: For long bus runs to maintain signal integrity.

- Shielded twisted pair cable (analog grade): Reduces noise pickup on low‑level voltage inputs.

If you need the exact channel pinout or Modbus register map for your PLC, share the host model and we’ll match a register template. One thing I appreciate is how predictable the addressing usually is on HIMI AI modules, which saves time during FAT/SAT.

Reviews

There are no reviews yet.