Description

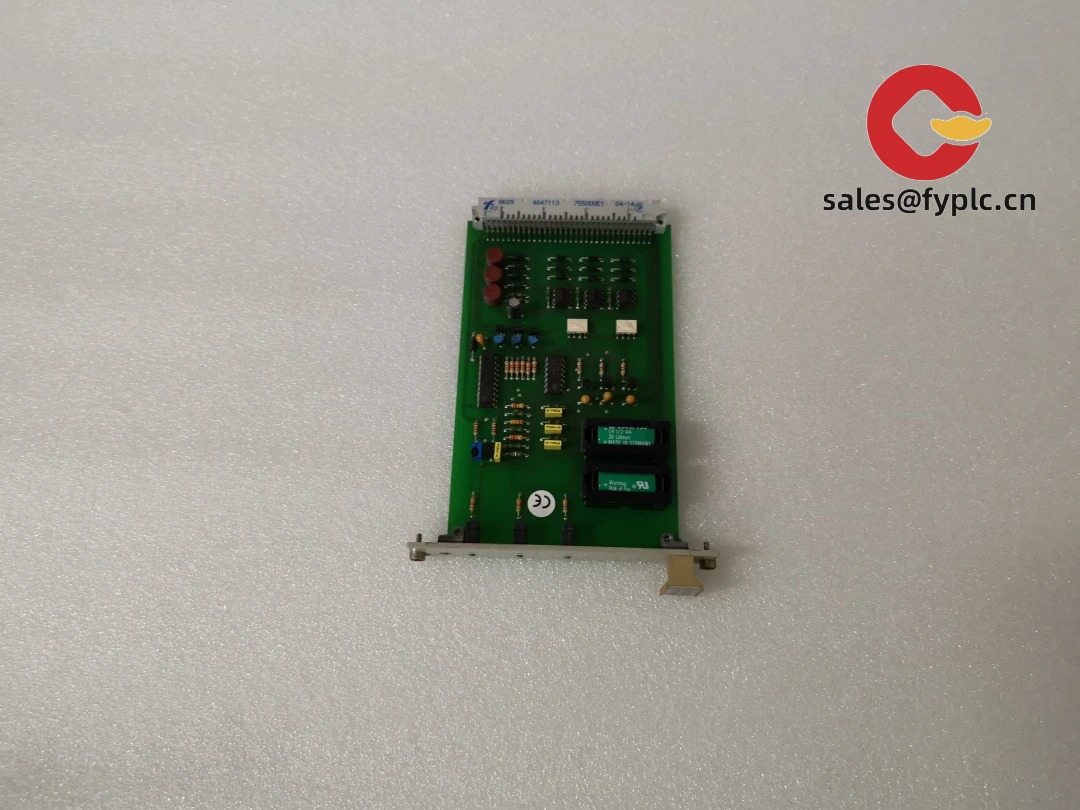

HIMI F7131 Digital Output Module – Reliable digital switching for industrial control

The HIMI F7131 is a digital output module designed for stable, repeatable switching of field devices in PLC and safety-adjacent control systems. From my experience, it suits applications where you need clean 24 VDC output signals to drive solenoids, interposing relays, signal lamps, and compact actuators—without babysitting nuisance trips. You might notice that users pick this model when they want straightforward wiring, system-level diagnostics, and long-term availability in brownfield upgrades.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Industrial digital outputs – Typically 24 VDC sourcing outputs for driving solenoids, indicators, and small relays.

- Channel isolation and protection – It usually includes galvanic isolation from logic and short-circuit/overload protection to safeguard the controller.

- Backplane integration – Designed to slot into the HIMI system base/backplane for fast installation and deterministic bus communication.

- Diagnostic feedback – In many cases supports per-channel fault/health indication, which helps reduce troubleshooting time on site.

- Detachable terminal connectors – Field wiring is typically simplified with plug-in terminals for tidy cabinet layouts.

- Lifecycle-friendly choice – Commonly used in brownfield upgrades where drop-in compatibility and stable firmware matter.

Technical Specifications

| Brand / Model | HIMI F7131 |

| HS Code | 8538.90 (Parts for switching/protective apparatus) |

| Power Requirements | 24 VDC system supply via backplane (module consumption typically < 5 W) |

| Signal Output Type | Digital Output, 24 VDC sourcing (typical); channel count varies by sub-variant |

| Communication Interfaces | System backplane bus (no external fieldbus on the module itself) |

| Installation Method | Rack/backplane mounting in control cabinet; plug-in terminal blocks for field wiring |

| Operating Temperature | 0 to +60 °C (typical industrial range) |

| Dimensions & Weight | Approx. 128 × 22 × 120 mm; ~0.20–0.25 kg (varies by terminal option) |

Application Fields

You’ll typically see the F7131 in discrete and process environments where dependable 24 VDC output switching is required:

- Oil & Gas skids (valve actuation, permissive lamps, ESD outputs)

- Chemical and pharma (batch equipment, dosing skid outputs)

- Power generation (aux pumps, dampers, trip relays via interposing)

- Water & wastewater (blower/valve control, status indications)

- Factory automation (safety-related signaling, machine I/O expansion)

A packaging OEM told us their maintenance crew liked that “channel diagnostics saved us a Saturday shift” after a wiring short—seems to be a common theme with this family.

Advantages & Value

- Reliability – Solid-state design with isolation tends to reduce nuisance trips and module damage from field faults.

- Compatibility – Fits HIMI rack/backplane systems; easy drop-in for expansions or replacements in many cases.

- Cost control – Diagnostics and modular wiring help cut downtime and technician hours.

- Technical support – We assist with cross-checking sub-variants, wiring pinouts, and migration notes.

Installation & Maintenance

- Cabinet & environment – Install in a clean, ventilated control cabinet; avoid condensation and corrosive gasses. Keep ambient within the stated operating range.

- Mounting – Seat the module firmly on the designated HIMI backplane slot. Ensure locking tabs are engaged before powering the system.

- Wiring – Use correctly sized wires for the output current rating; separate high-inductive loads from signal wiring; add flyback diodes across DC coils when applicable.

- Grounding – Maintain a low-impedance reference ground; follow cabinet bonding best practices to minimize transient stress.

- Safety – Isolate power before inserting or removing modules unless the system explicitly supports online replacement for this variant.

- Routine checks – Periodically retighten terminals, verify LED/channel diagnostics, and keep firmware/configuration backups if the platform supports them.

Quality & Certifications

- CE compliant; RoHS alignment typical for this family

- UL/cUL availability may vary by series and production batch

- Manufacturer quality systems commonly aligned with ISO-based processes

- Warranty: 365 days (repair/replace as applicable)

Suggested Complementary Components

- HIMI system backplane/base unit (F7xxx series) – required slot interface and power distribution.

- HIMI CPU/Controller module – central processor for the I/O stack.

- HIMI F712x Digital Input Module – matched DI module for sensors/contacts.

- 24 VDC power supply with adequate hold-up time – sized for module plus field load.

- Interposing relay terminal blocks – for driving higher-power or AC loads safely.

One thing I appreciate is how the F7131 fits neatly into brownfield panels—wiring usually lines up, and the diagnostics make commissioning less painful. If you’re standardizing on a lean bill of materials, this module tends to keep the stockroom happy.

Reviews

There are no reviews yet.