Description

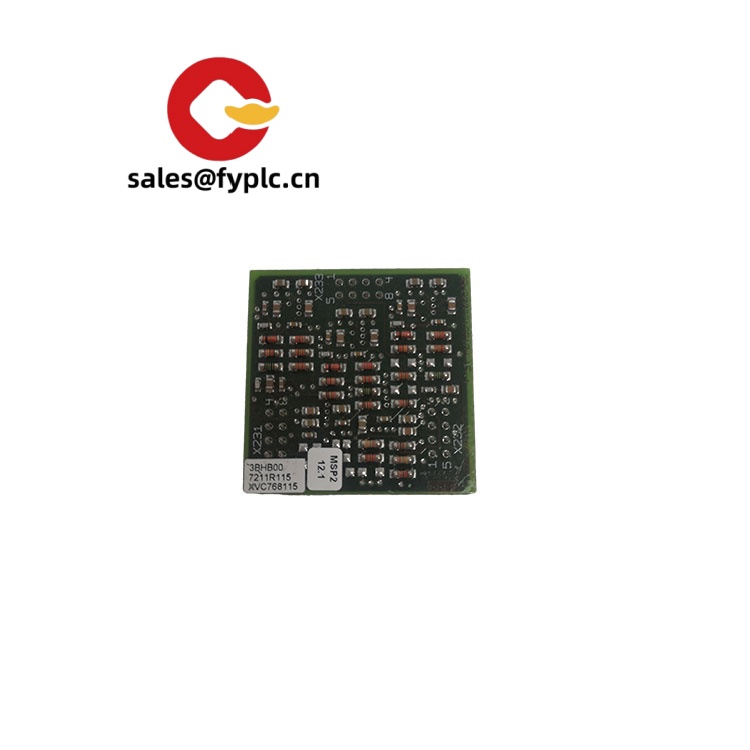

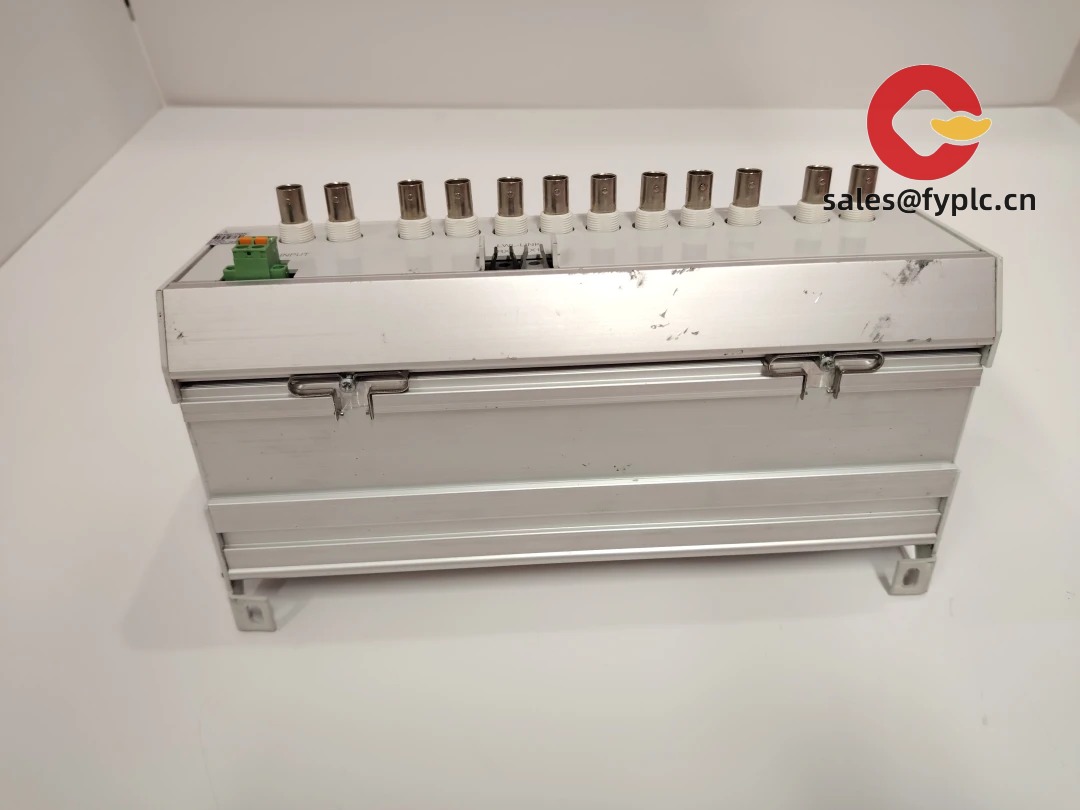

ABB XUD194 / XUD194A (3BHC018137R0001) – Compact control module for ABB automation cabinets and retrofit projects

The ABB XUD194-XUD194A-3BHC018137R0001 is a compact control/expansion module used in ABB automation systems for reliable signal handling and cabinet integration. From my experience, this unit typically serves as a field I/O or interface element in process plants and manufacturing lines where uptime and clean wiring matter. You might notice that it’s often chosen for drop‑in replacements during shutdowns because it fits standard cabinet layouts and plays nicely with existing ABB architecture.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment for delivery

- Express options: FedEx, UPS, DHL

Key Features

- Purpose-built for ABB cabinets – Typically used as a control/interface module within ABB automation racks, easing retrofit work.

- 24 VDC control environment – Designed to run in standard 24 VDC control power systems common in process plants.

- Stable signal handling – Intended for reliable digital/field interfacing where consistent scan and response times are critical.

- Space-efficient hardware – Compact footprint for dense panels; helps keep door depth and cable routing under control.

- Service-friendly design – From my experience, modules in this family are straightforward to swap, minimizing downtime.

- Good compatibility in brownfield sites – Fits into many existing ABB systems without reworking the entire cabinet scheme.

Technical Specifications

| Brand / Model | ABB XUD194 / XUD194A – 3BHC018137R0001 |

| HS Code | 8537.10 (Control panels/PLC modules – typical classification) |

| Power Requirements | 24 VDC nominal; low power module (consumption varies by application) |

| Operating Temperature | 0 to +55 °C (typical control cabinet conditions) |

| Signal I/O Types | Digital/field interface module; exact channel mix depends on system configuration |

| Communication Interfaces | Backplane/system bus integration within ABB control architecture |

| Installation Method | Panel/DIN-rail mounting in an enclosed control cabinet; pluggable wiring typical |

| Dimensions & Weight | Compact module format; commonly used in 100–130 mm height panel slots (contact us for exact data) |

Application Fields

This module is typically deployed in process automation and machinery control where stable digital interfacing is required. You’ll often find it in:

- Oil & gas and chemical plants – panel upgrades and brownfield I/O consolidation

- Power generation – turbine balance-of-plant I/O and interlock panels

- Food & beverage – packaging line control cabinets with tight space constraints

- Metals & mining – ruggedized cabinets near drives and motor control centers

- Water & wastewater – lift station and treatment plant local I/O nodes

A maintenance lead at a packaging facility told us, “The XUD194A swap took under 20 minutes and the line came back clean—no need to re-terminate the whole block,” which, in many cases, is exactly the outcome you want on a tight shutdown window.

Advantages & Value

- Reliability – Designed for continuous-duty environments; helps cut nuisance trips and intermittent signals.

- Compatibility – Seems to be well-matched with existing ABB system buses and cabinet wiring practices.

- Cost Control – Short installation time and minimal rewiring typically reduce shutdown labor costs.

- Lifecycle Support – Ideal for maintaining installed ABB bases while planning phased upgrades.

Installation & Maintenance

- Cabinet environment: Mount in a closed control cabinet with basic ventilation; avoid direct heat sources and moisture.

- Wiring: Use ferruled conductors for screw/pluggable terminals; segregate signal and power cables to limit noise.

- Power: 24 VDC supply with proper grounding; keep ripple within typical control limits.

- Safety: De-energize before handling; follow lockout/tagout; ESD protection during module swaps.

- Routine maintenance: Quarterly dust removal, yearly terminal re-torque; check firmware/parameters where applicable.

- Spare strategy: Keep one on the shelf for critical loops; from my experience, it prevents extended downtime during unplanned events.

Quality & Certifications

- CE compliant for industrial control environments

- UL/cUL recognition is common for ABB control modules (verify per serial and revision)

- RoHS conformity in most cases; documentation available on request

- Manufacturer’s quality system aligned with ISO standards

- Warranty: 365 days

Need a matched terminal base, 24 VDC cabinet power supply, or spare wiring kits for ABB XUD194/XUD194A integration? We can recommend compatible accessories to streamline installation and reduce on-site time.

Reviews

There are no reviews yet.